Battery temperature control method and device for new energy vehicle

A new energy vehicle and battery technology, applied in battery temperature control, secondary batteries, circuits, etc., can solve the problems of poor battery temperature control, affecting battery working efficiency, etc., and achieve fast control response, low cost, and accurate temperature control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

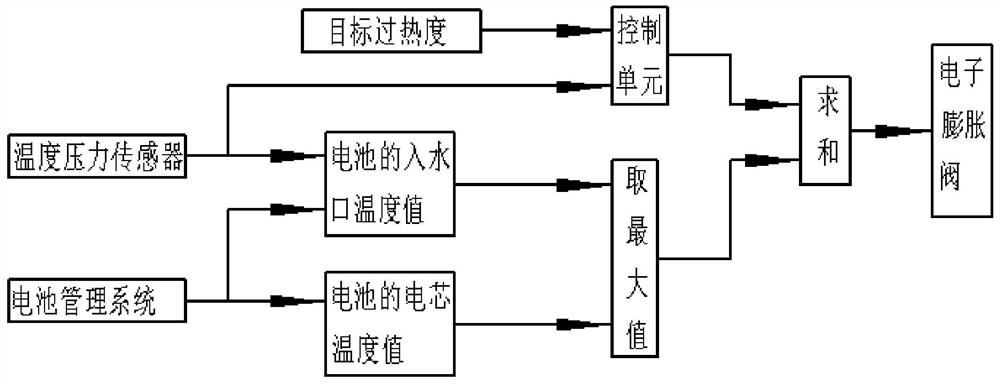

[0073] Such as figure 1 with figure 2 As shown, the present invention provides a battery temperature control method for a new energy vehicle, including:

[0074] Obtain the refrigerant flow base value of the battery cooler according to the water inlet temperature value of the battery and the cell temperature value of the battery;

[0075] Obtain the refrigerant flow correction value of the battery cooler according to the superheat degree of the refrigerant outlet of the battery cooler;

[0076] The final value of the refrigerant flow of the battery cooler is obtained according to the basic value of the refrigerant flow and the correction value of the refrigerant flow.

[0077] In this embodiment, the basic value of the refrigerant flow rate of the battery cooler is obtained according to the temperature value of the water inlet of the battery and the temperature value of the battery cell, including:

[0078] Use the larger temperature value of the water inlet temperature va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com