A Direct Contact Heat Dissipation Method for Vibrating Devices Based on Microarray Structure

A technology of microarray structure and vibration device, which is applied in the construction parts of electrical equipment, nanotechnology for materials and surface science, electrical components, etc., can solve the fretting wear of piezoelectric transformer electrode surface contact and reduce the service life of transformer and performance, affecting the performance of the piezoelectric transformer and other issues, to ensure the direct contact area, improve the service life, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The following takes carbon nanotube microarray as an example of thermal interface material to explain its application in heat dissipation of piezoelectric transformer in detail:

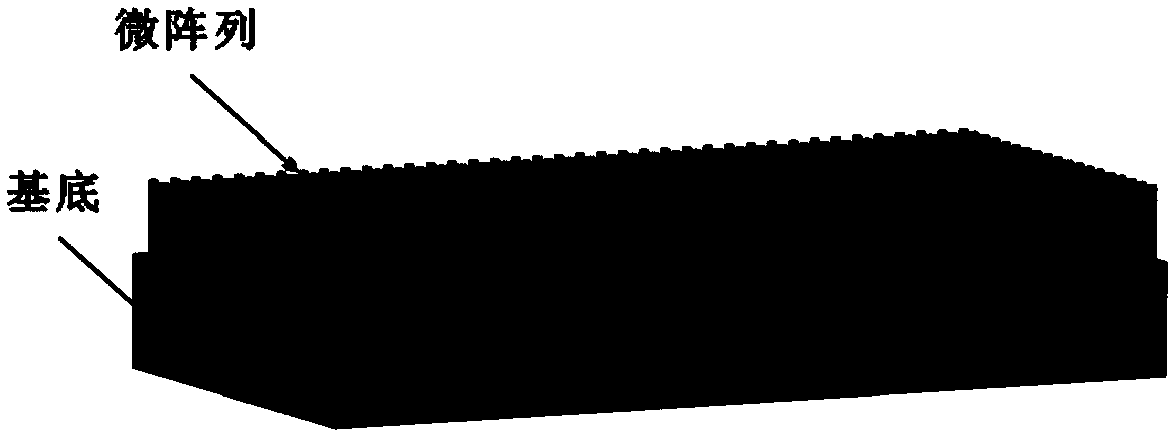

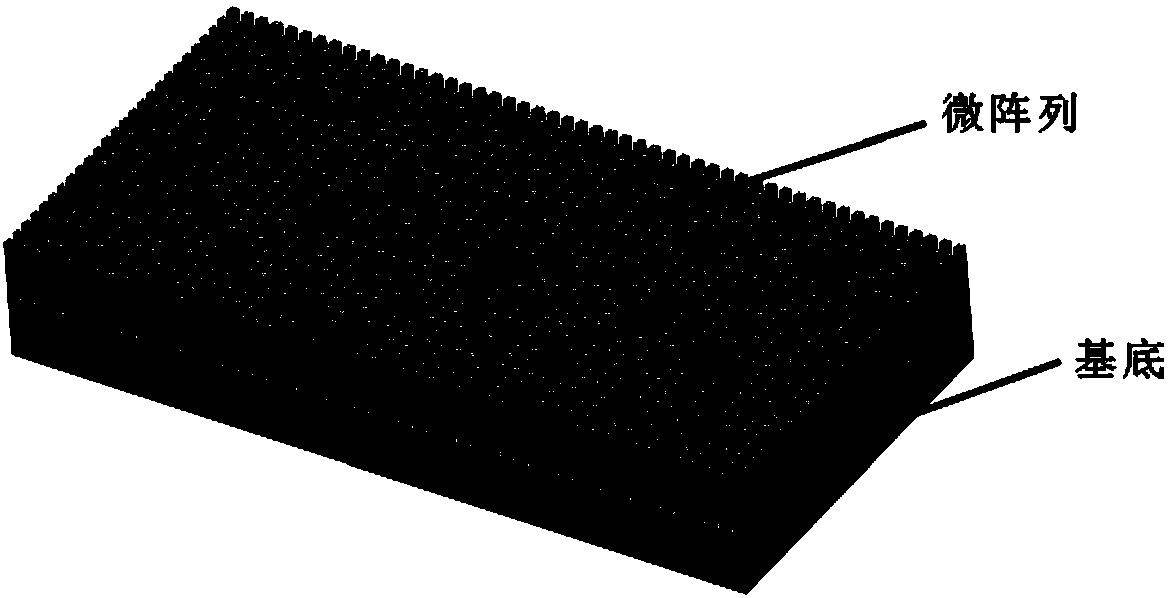

[0031] Figure 1a It shows the microarray structure of carbon nanotubes grown on a rectangular silicon wafer substrate. The carbon nanotubes are vertically arranged and distributed on the substrate. The thermal conductivity measured by laser interferometry is 10-20W / m·K.

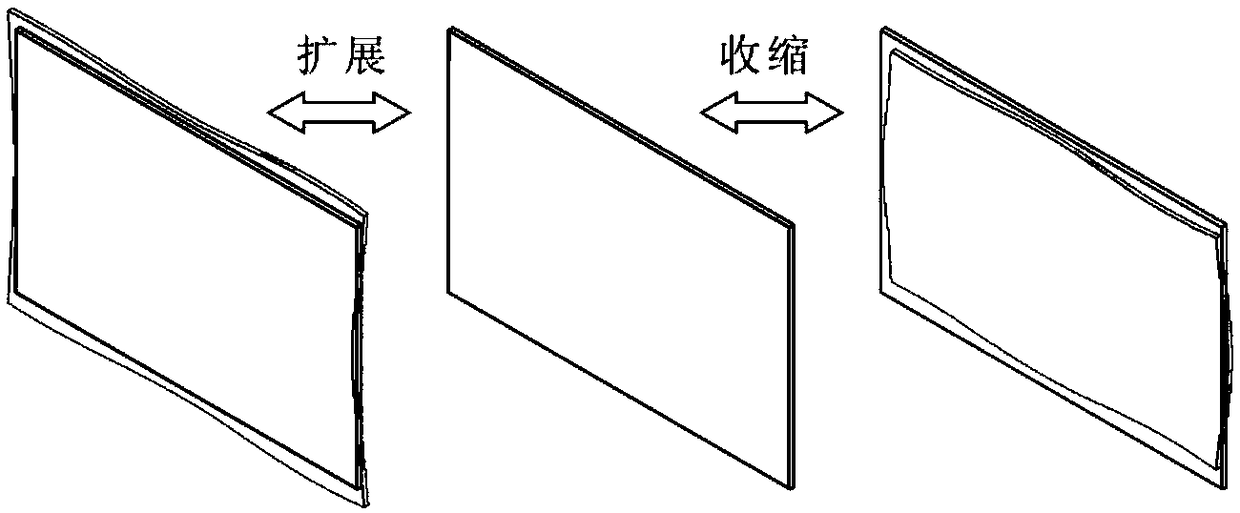

[0032] figure 2 A schematic diagram of the rectangular piezoelectric transformer to be subjected to heat dissipation treatment and its plane expansion mode shape is shown in this embodiment. The piezoelectric transformer is in a state of high-frequency vibration in the lateral direction. If a rigid radiator is directly used for contact heat dissipation, there will be relative sliding between the stationary radiator and the transformer, which will affect the vibration performance of the transformer; at the same time, contac...

Embodiment 2

[0037] Carbon nanotube microarray structure heat dissipation application technical scheme in columnar vibration devices:

[0038] Figure 5 Figure a in Fig. 1 shows a schematic diagram of the torsional vibration mode of the piezoelectric ceramic tube. For this kind of circular vibration device, because it is not in a normal plane motion state, it is usually inconvenient to manage its heat dissipation.

[0039] Figure 5 Figure b in is a schematic diagram of a carbon nanotube microarray structure grown radially on the inner wall of a circular substrate. Based on the high thermal conductivity and high flexibility of the above-mentioned carbon nanotube array, it can reduce the thermal resistance of the contact surface in the application of contact heat dissipation, and there is no relative sliding and no contact wear, so it can be used for thermal management applications of circular vibration devices.

[0040] Figure 6 It is a schematic diagram of the application of the radi...

Embodiment 3

[0042] The following takes copper nanowire microarray as an example of thermal interface material to explain its application in heat dissipation of piezoelectric transformer in detail:

[0043] Figure 1b It shows a copper nanowire microarray structure processed by laser etching or photolithography on a rectangular copper substrate. The copper nanowires are vertically arranged and distributed on the substrate. The unit is a cuboid with a cross-sectional size of about 100 nanometers. The height is in the order of microns, and the array density is about 1%.

[0044] For the piezoelectric transformer in the planar expansion working mode, the copper nanowire microarray structure is used for the embodiment of contact heat dissipation, which can also be used image 3 A schematic diagram showing the heat dissipation structure of the scheme. The piezoelectric transformer is directly in contact with the copper nanowire arrays vertically arranged and distributed on the substrate. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com