Leather tanning machine

A tanning and leather technology, applied in the field of clothing, can solve the problems of large tanning dose, leather immersion, excessive tanning, etc., and achieve the effects of ensuring processing quality, promoting absorption, and saving use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

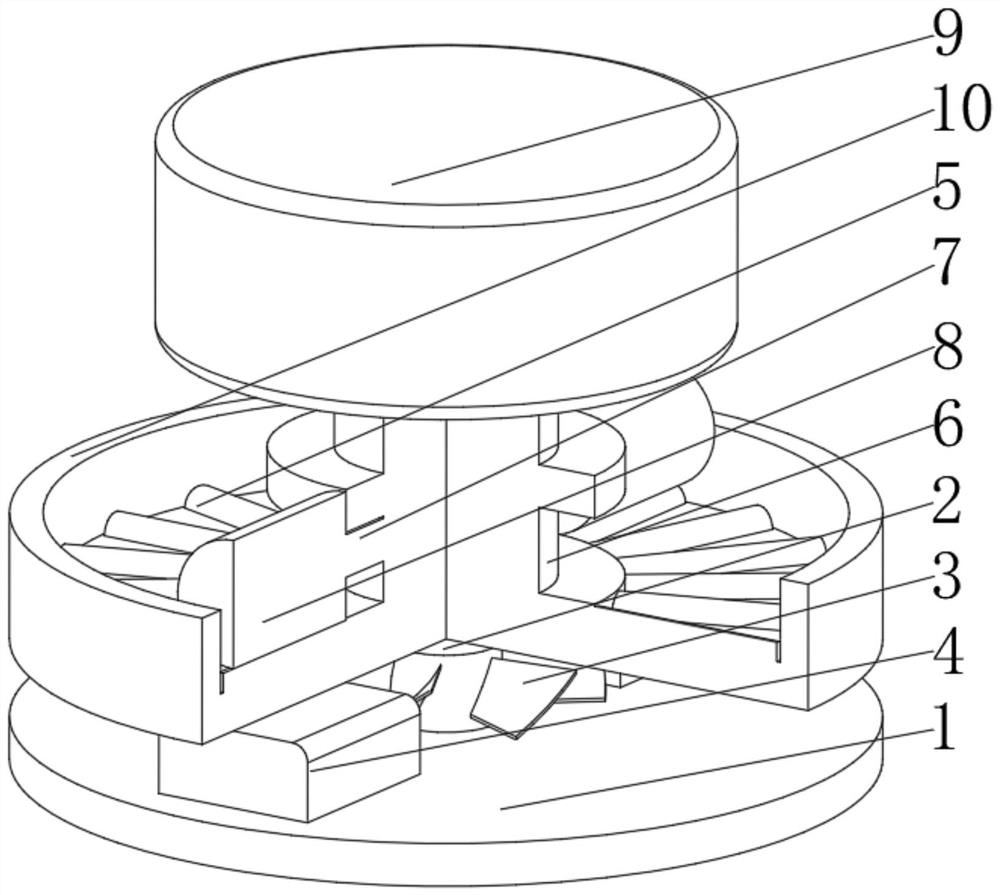

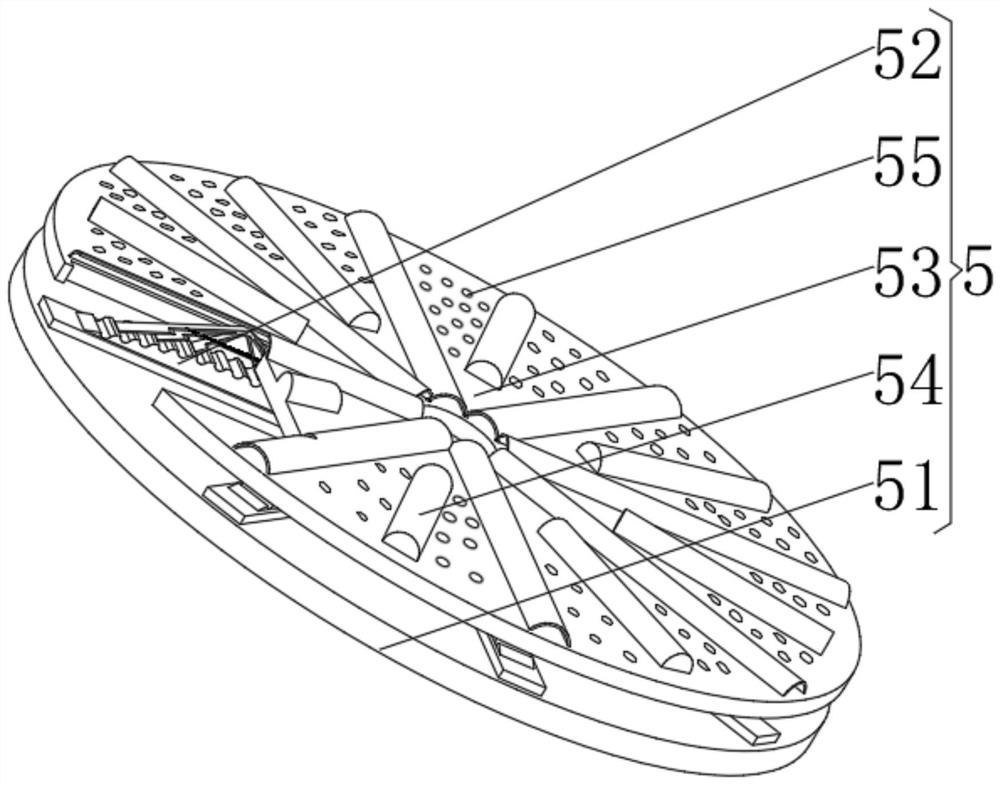

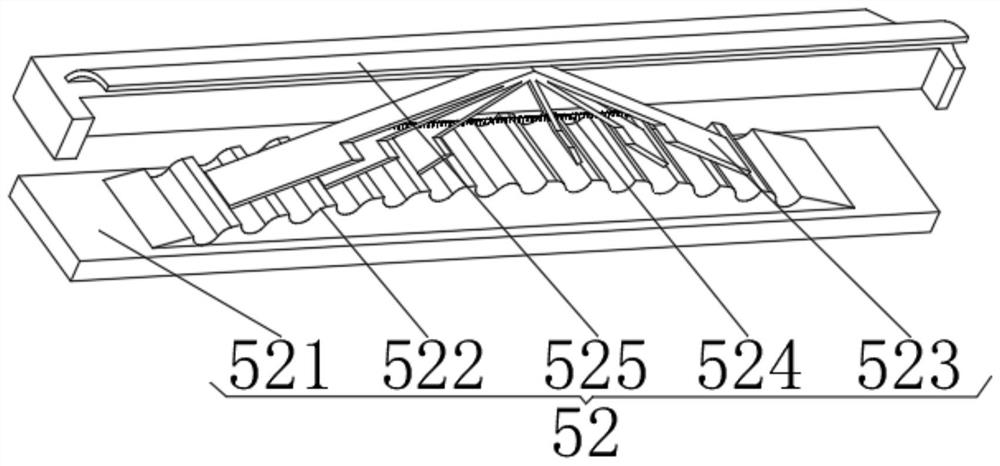

[0036] Such as Figure 1-5 As shown, a leather tanning machine proposed by the present invention includes a protection base 1, an adapter shaft 2 is fixedly connected to the middle position of the top of the protection base 1, and a power fan blade 3 is fixedly connected to the outer surface of the adapter shaft 2, and the top of the protection base 1 The side of the power fan blade 3 away from the transfer shaft 2 is fixedly connected with a magnetic block 4, the outer surface of the transfer shaft 2 is located above the power fan blade 3 and is movably connected with a tanning disc 5, and the top of the transfer shaft 2 is fixedly connected with a motor column 6 , the output ends of the front and back of the motor column 6 are connected to the tanning wheel 8 through the transmission shaft 7, the motor column 6 is away from the transfer shaft 2 and the top is fixedly connected to the tanning agent mechanism 9, and the outer surface of the tanning disc 5 is fixedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com