Turbine shell laryngeal structure

A turbine shell and mouthpiece technology, applied to engine components, machines/engines, internal combustion piston engines, etc., can solve the problems of turbocharger speed increase, turbine efficiency reduction, turbine flow capacity reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

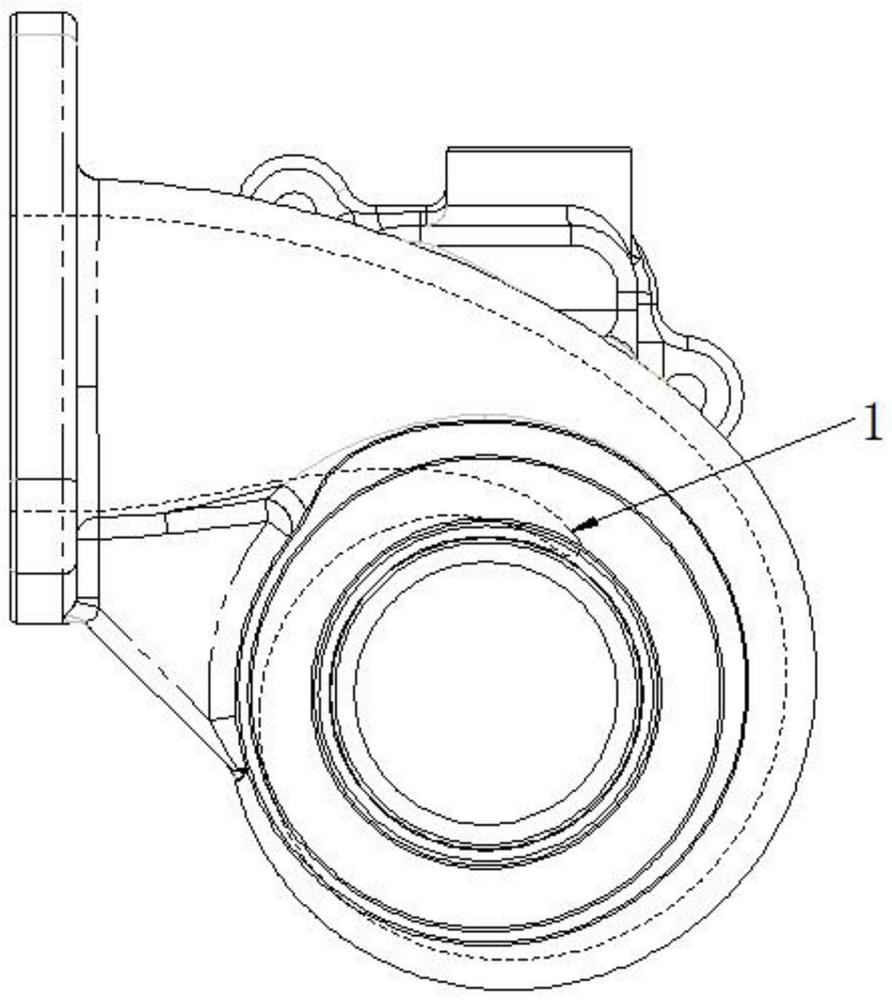

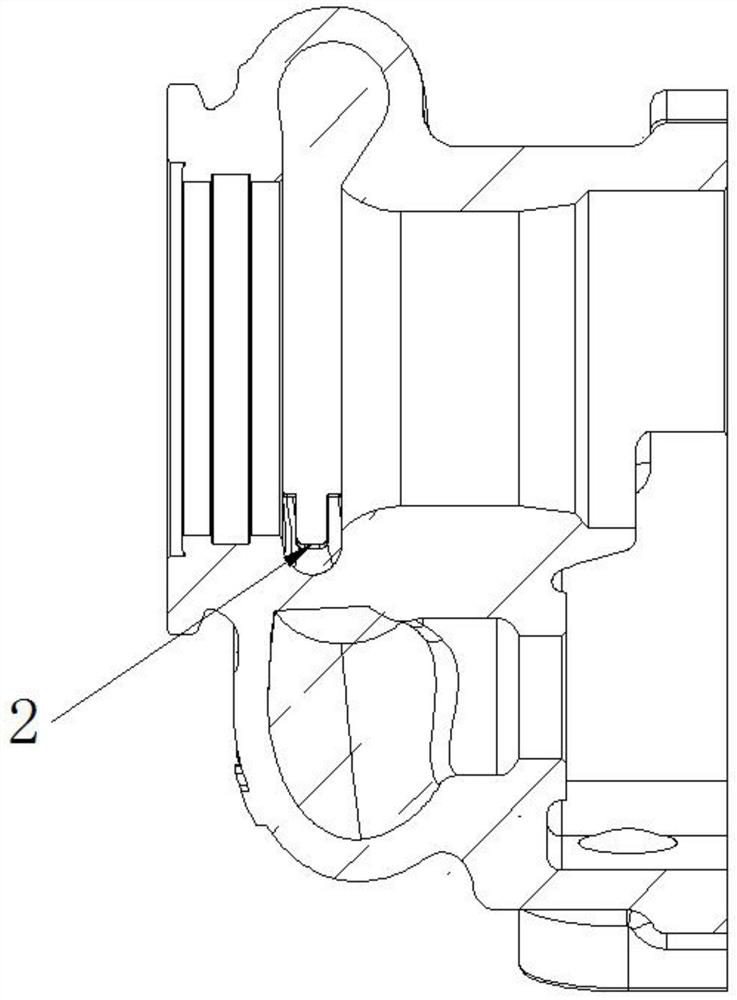

[0049] Such as figure 1 and figure 2 As shown, the mouthpiece structure of the turbine casing includes the mouthpiece, and a diversion groove is opened at the mouthpiece.

[0050] The guide slot includes an intermediate groove structure, which is suitable for large turbochargers.

[0051] The groove width of the middle groove structure is 2-6mm, and the groove depth is 1-15mm.

Embodiment 2

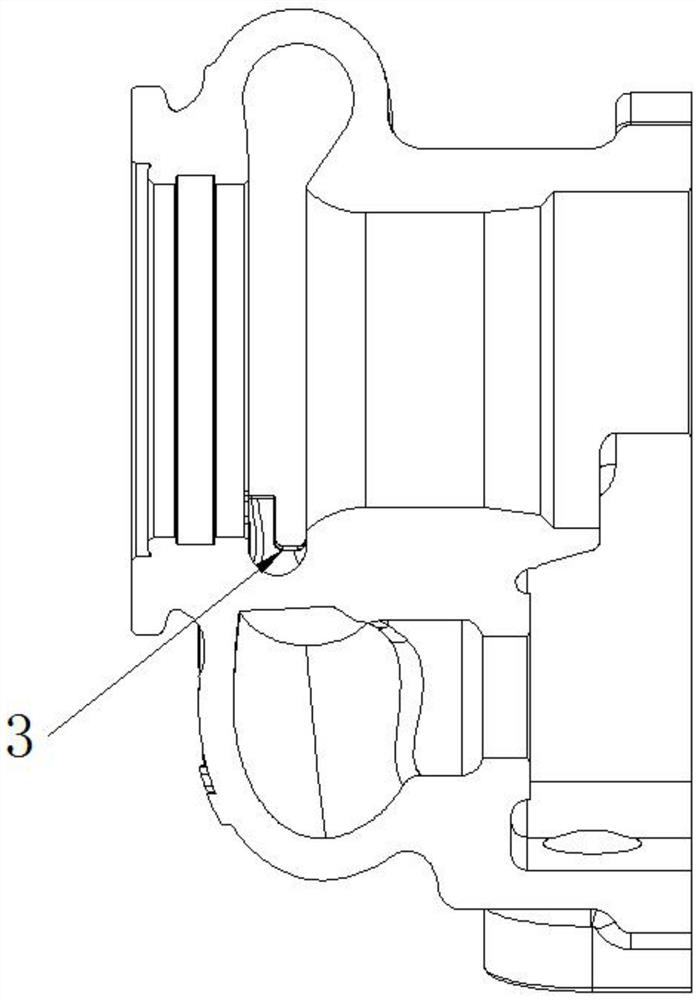

[0053] Such as image 3 and Figure 4 as shown,

[0054] The diversion groove includes a lower groove structure, which is suitable for medium and small turbochargers; the static pressure value of the turbine inlet with the side groove scheme is reduced by about 0.2kPa as a whole, and is improved by about 2.5%; the excitation force of the turbine shell with the original mouthpiece structure is 1700Pa , After optimizing the structure of the mouthpiece, the exciting force of the turbine shell is 1430Pa, and the exciting force of the turbine shell is improved by 15.9%; after optimizing the structure of the mouthpiece, the efficiency of the turbine is increased by about 2%;

[0055] The groove bottom of the lower groove structure is gradually expanded from one side of the groove wall to the other groove wall.

[0056] The groove width of the lower groove structure is 2-6mm, and the groove depth is 1-15mm.

Embodiment 3

[0058] Such as Figure 5 as shown,

[0059] The guide slots include oblique groove structures, which are especially suitable for small turbochargers.

[0060] The inclined groove structure is arranged obliquely on one side of the groove wall near the gas outlet end of the turbine casing.

[0061] The groove depth of the oblique groove structure is 1-15mm, and the slope is 10-60°.

[0062] Such as Figure 7-9 as shown,

[0063] The middle groove structure, the lower groove structure, and the oblique groove structure can obviously improve the BPF noise of the turbine.

[0064] Such as Figure 10-12 as shown,

[0065] The relationship between the pressure amplitude and frequency can be obtained by taking the average value of the turbine inlet static pressure and performing Fourier transform. The pressure amplitude represents the excitation of the airflow to the turbine. The lower the pressure amplitude, the smaller the force of the airflow on the turbine blades, which is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com