Optimization method of pressure flow path of cooling jacket in thrust chamber of full flow afterburning cycle engine

An optimization method and thrust chamber technology, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of high pressure bearing of cooling jacket and unsatisfactory heat exchange requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

[0016] The method for optimizing the pressurized flow path of the thrust chamber cooling jacket of the full-flow afterburning cycle engine provided by the present invention comprises the following steps:

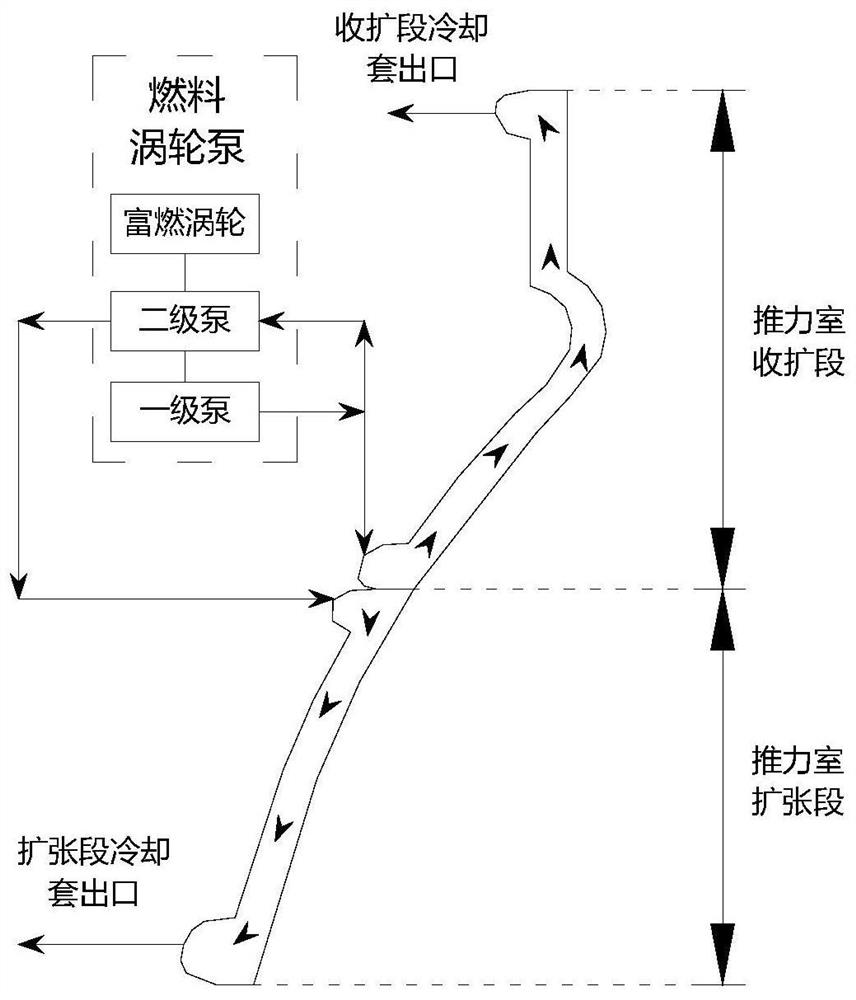

[0017] Firstly, the pump in the fuel turbine pump is designed as a two-stage cascade type composed of a primary pump and a secondary pump, both of which are driven by a fuel-rich turbine;

[0018] Then, the outlet of the first-stage pump is divided into two paths, one of which is connected to the inlet of the cooling jacket of the retraction and expansion section of the thrust chamber, and the other outlet is connected to the inlet of the second-stage pump, and the outlet of the second-stage pump is connected to the cooling jacket of the expansion section of the thrust chamber The inlet leads the outlet of the cooling jacket of the thrust chamber expansion section to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com