Engineering machinery shock absorber and shock absorption method thereof

A technology for construction machinery and shock absorbers, which is applied in the direction of shock absorbers, springs/shock absorbers, chemical instruments and methods, etc., and can solve the problems of easy shock absorption and failure of shock absorbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

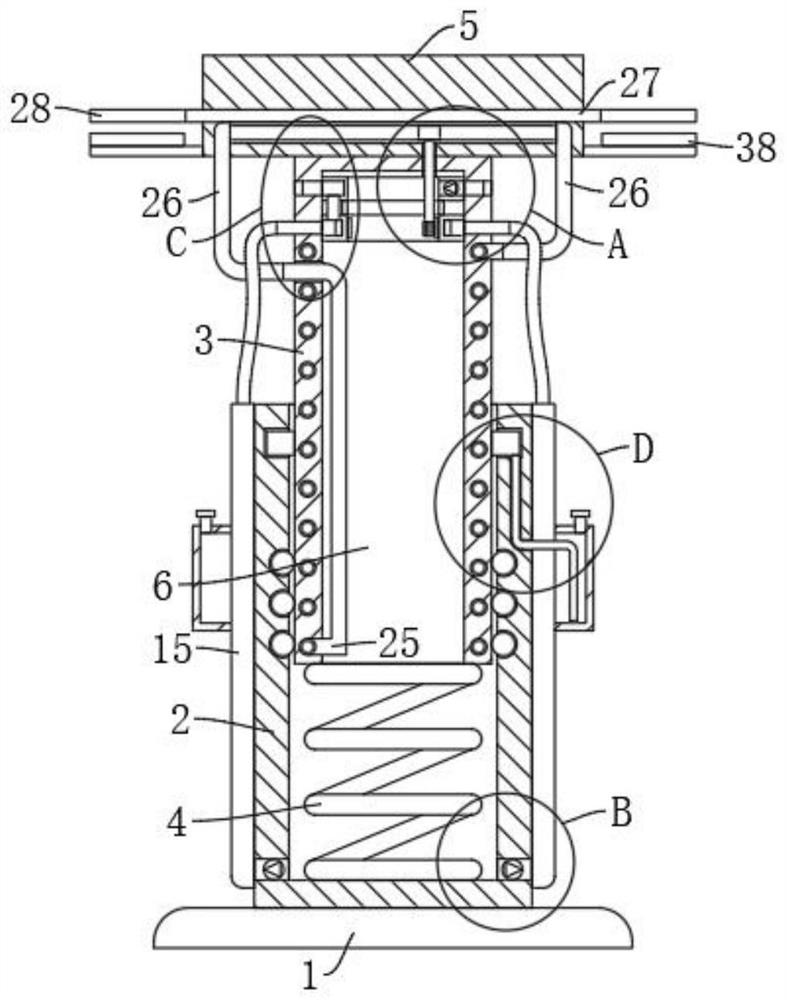

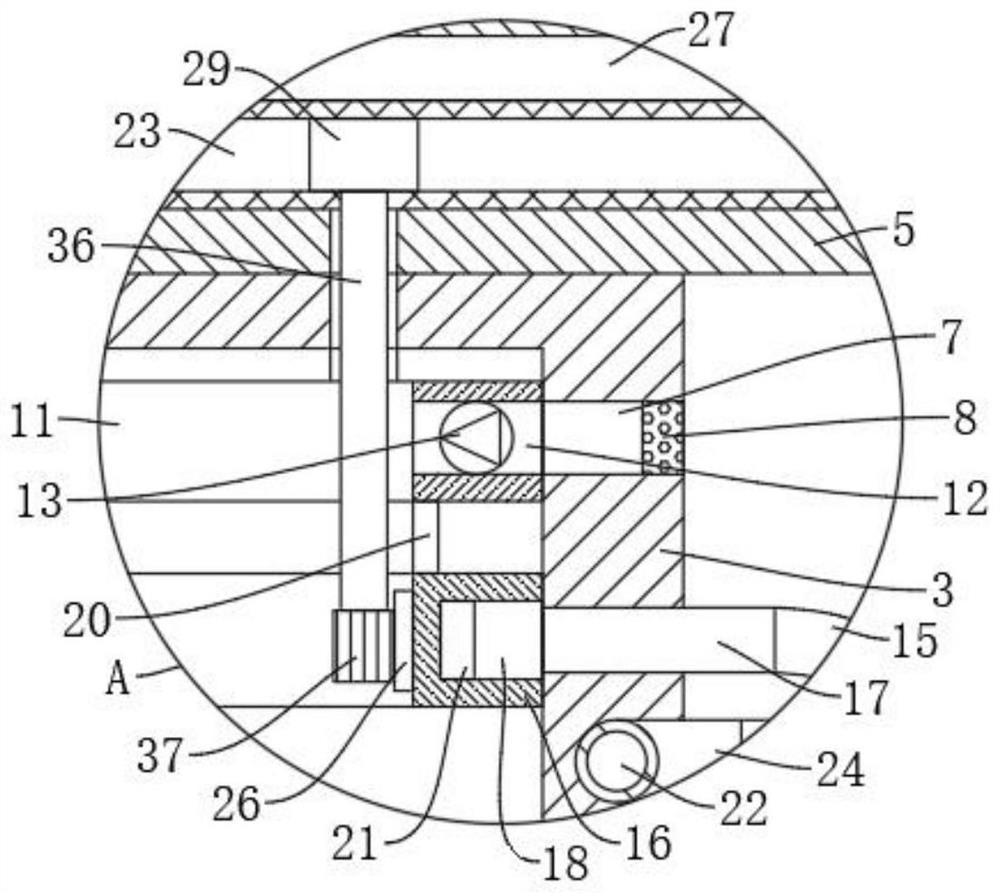

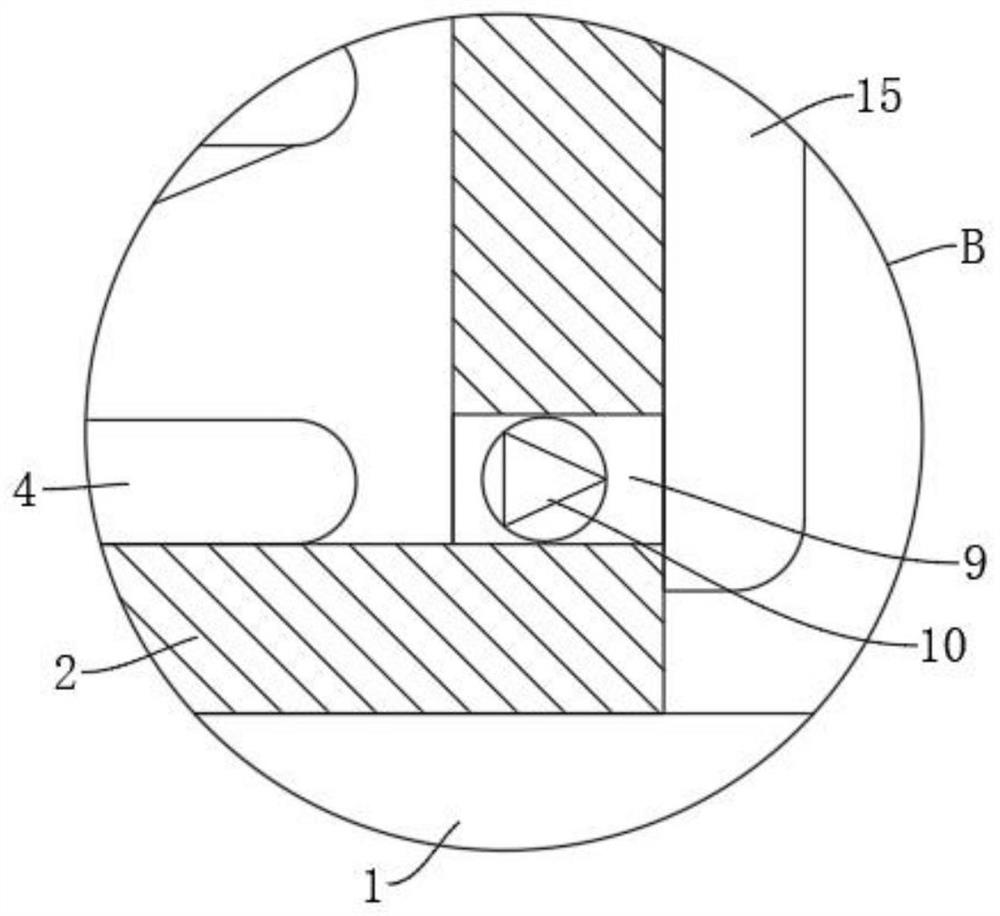

[0040] refer to Figure 1-8 , a shock absorber for construction machinery, comprising a base 1, the upper end of the base 1 is fixedly connected with a buffer sleeve 2, the inner top of the buffer sleeve 2 is provided with a damping slide bar 3 slidingly connected with it, and the damping slide bar 3 is connected with the buffer The inner bottom of the sleeve 2 is elastically connected by a damping spring 4, the upper end of the damping slide bar 3 is fixedly connected with a support plate 5, the lower end of the damping slide bar 3 is provided with a cooling groove 6, and the upper end outer wall of the cooling groove 6 is provided with There are a plurality of suction ports 7 distributed in a circle, dust-proof nets 8 are fixedly installed in the entrances of the plurality of suction ports 7, and the outer wall of the lower end of the buffer sleeve 2 is provided with a plurality of exhaust ports 9 distributed in a circle. The first one-way valve 10 is fixedly installed in ea...

Embodiment 2

[0043] refer to Figure 1-4 and Image 6 , is basically the same as Embodiment 1, furthermore: the self-cleaning mechanism includes a plurality of air inlets 17 arranged on the outer wall of the shock absorbing slide bar 3, and the plurality of air inlets 17 are respectively connected to the plurality of air inlets through the first hose 15. Two exhaust ports 9 are fixedly connected and communicated, and the inner circumference of the cooling groove 6 is connected to the lower ring 16 by rotation, and the lower ring 16 is fixedly connected to the upper ring 11 through the connecting rod 20, and the outer wall of the lower ring 16 is provided with The annular groove 18 that air hole 17 communicates, the inner top of annular groove 18 is provided with the connecting pipe 19 that extends to the upper end of lower ring 16, the end of connecting pipe 19 is fixedly connected and communicated with blind hole 14, and the inner wall of annular groove 18 is fixedly connected with A plu...

Embodiment 3

[0045] refer to figure 1 , figure 2 , Figure 7 and Figure 8 , which is basically the same as that of Embodiment 1, furthermore: the circulation cooling mechanism includes a helical tube 22 fixedly connected to the inner wall of the shock absorbing slide bar 3, and the two ends of the helical tube 22 are respectively provided with a first inlet 24 and a second inlet 25, The inside of the support plate 5 is fixedly equipped with a curved tube 23, both ends of the curved tube 23 are fixedly connected to the first inlet 24 and the second inlet 25 respectively through the second hose 39, and the upper end of the curved tube 23 is fixedly connected to a The heat dissipation plate 27 on the outer wall of the plate 5, the inner wall of the lower ring 16 is fixedly equipped with a ring gear 26, the inner top of the cooling groove 6 is rotatably connected with a rotating shaft 36, and the lower end of the rotating shaft 36 is fixedly connected with a driven gear 37 meshing with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com