Detachable deformable gear shifting handle

A shift handle and detachable technology, which is applied in the field of detachable deformable shift handles, can solve the problems of the shift handle not having disassembly and hammering functions, unable to achieve quick disassembly, and poor overall effect, etc. The arm, the overall function is perfect, the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

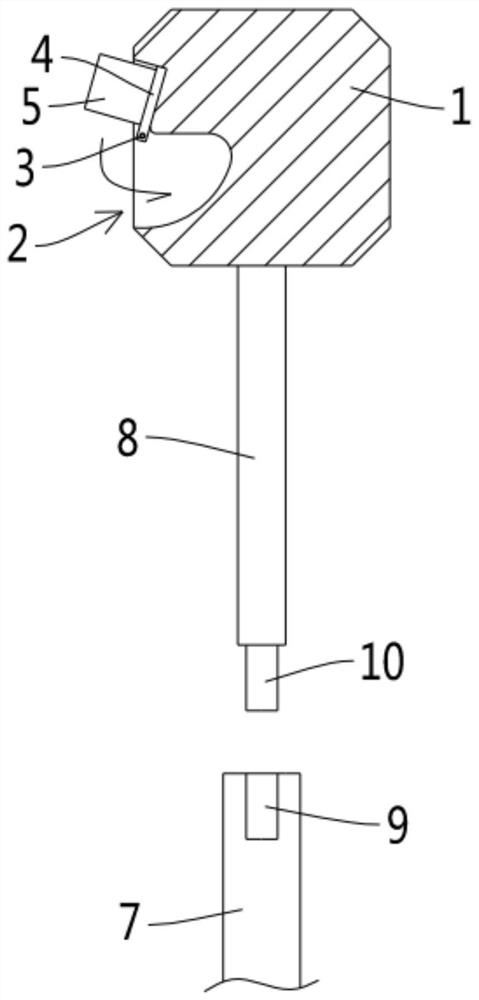

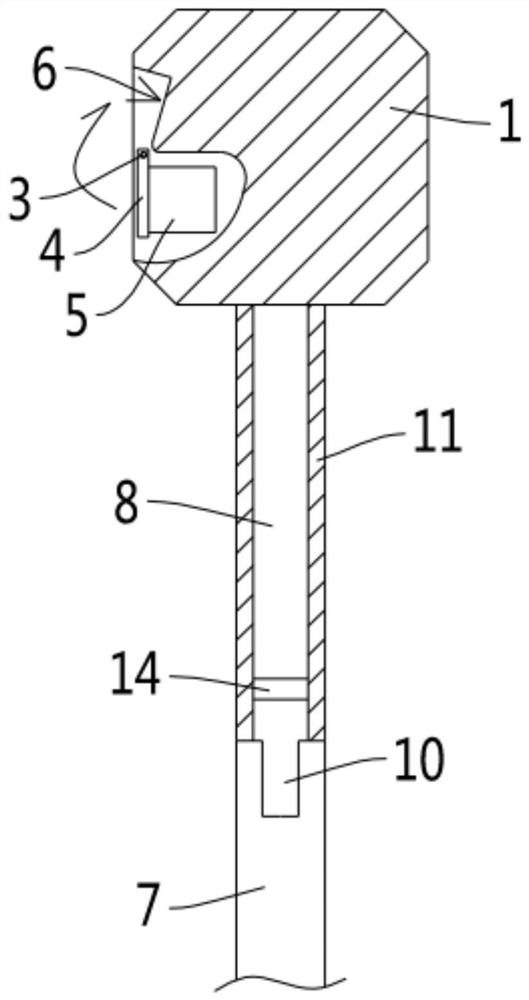

[0018] see figure 1 with figure 2 As shown, a detachable deformable shift handle involved in this embodiment includes a shift lever. One end of the shift lever is connected to the main body of the shifter, and the other end is provided with a shift handle 1 for gripping. The side of described shifting handball 1 is dug with hammerhead groove 2, is connected with rotating shaft 3 on the groove wall of hammerhead groove 2, and rotating shaft 3 is provided with the hammerhead seat 4 that rotates with it, and hammerhead seat 4 is provided with Hammer head 5, the shifting hand ball 1 is provided with a supporting platform 6 located in the hammer head groove 2, when the hammer head 5 rotates outside the hammer head groove 2, the hammer head seat 4 is against the bearing Stand 6; the shift lever is composed of a fixed lower rod 7 and a movable upper rod 8, the end surface of the fixed lower rod 7 facing the movable upper rod 8 is provided with a threaded hole 9, and the movable upp...

Embodiment 2

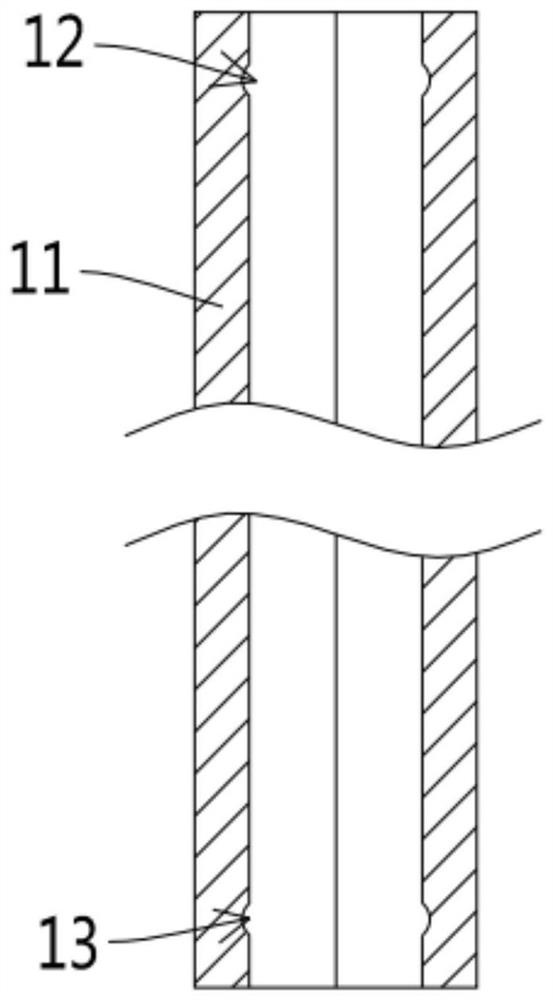

[0023] see Figures 1 to 5 As shown, a detachable deformable shift handle involved in this embodiment is further set on the basis of Embodiment 1, and the movable upper rod 8 is slidably connected with an extension sleeve 11, and the extension sleeve The inner pipe wall of the pipe 11 is dug with an upper limit groove 12 near one end and a lower limit groove 13 near the other end; the movable upper rod 8 is provided with side holes 14 at both ends communicating with the outside world, and the side holes 14 The axis of the shaft is perpendicular to the extending direction of the length of the movable upper rod 8, the steel ball 15 partially exposed in the side hole 14 is provided, and one end of the steel ball 15 is provided with a limiter that restricts it from rolling out of the side hole 14 completely. The other end of the position ring 16 has an elastic body 17 against the steel ball 15 , and the steel ball 15 partially exposed from the opening is embedded in the upper limi...

Embodiment 3

[0027] see Figures 1 to 5 As shown, a detachable deformable shift handle involved in this embodiment, on the basis of Embodiment 2, is further set as follows: a guide groove 18 is opened on the movable upper rod 8, and a guide groove 18 is opened on the guide groove 18 The length extension direction is the same as the length extension direction of the movable upper rod 8 , and a guide rail 19 arranged on the inner wall of the extension sleeve 11 is slidably connected to the guide groove 18 .

[0028] Preferably, the cross-sectional shape of the movable upper rod 8 is a regular hexagon; the inner hole of the extension sleeve 11 matches the movable upper rod 8 .

[0029] In this embodiment, the arrangement of the guide groove 18 and the guide rail 19 plays a role of sliding guide.

[0030] The detachable deformable shift handle involved in the present invention can be used as a hammer to strike the shift handle by removing the shift handle from the shifter main body and turnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com