Method for manufacturing a motor vehicle servo drive

A servo drive device and motor vehicle technology, applied in the direction of electromechanical devices, transmission device parts, control mechanical energy, etc., can solve the problems of high cost and high cost, and achieve the effects of reducing switching noise, simplifying installation, and improving transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

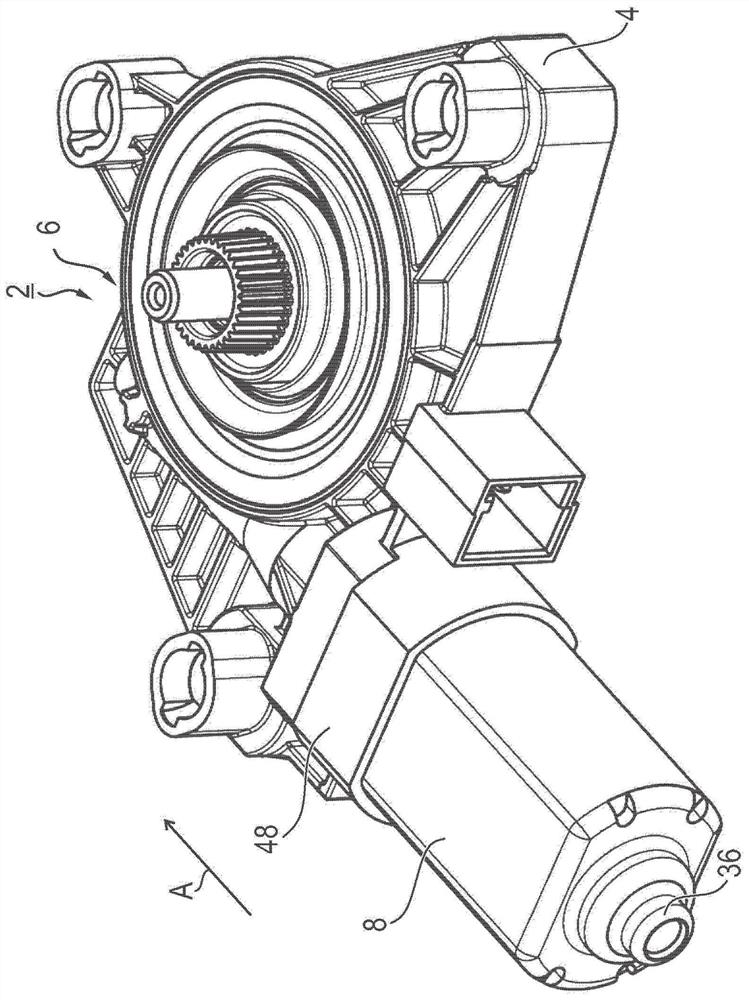

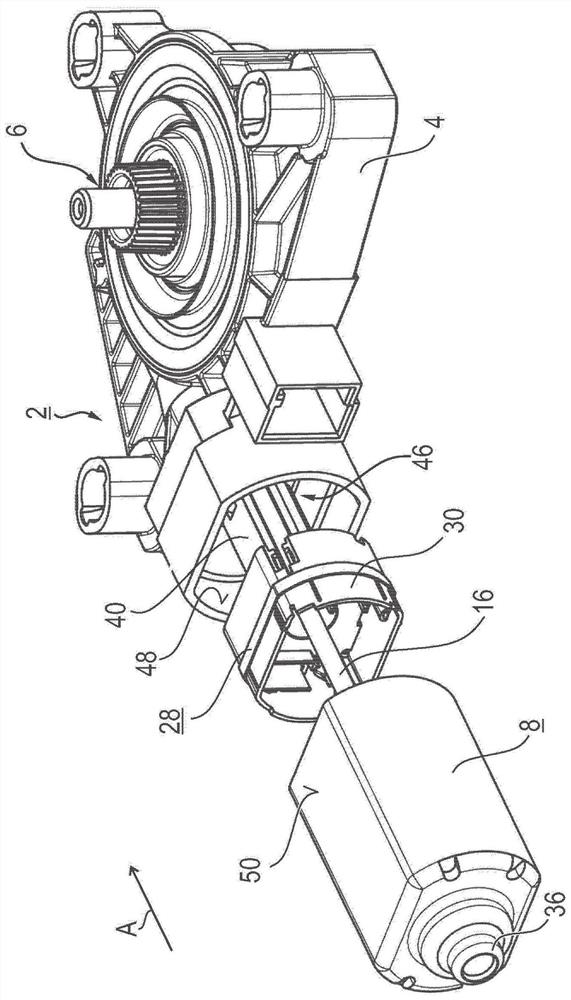

[0034] figure 1 A motor vehicle actuating drive 2 is shown, which comprises a transmission unit 6 with a transmission housing 4 and a motor unit 10 with a motor housing 8 . In the present embodiment, the motor vehicle actuating drive 2 is, for example, a window lift drive, a seat adjustment drive or a sunroof drive.

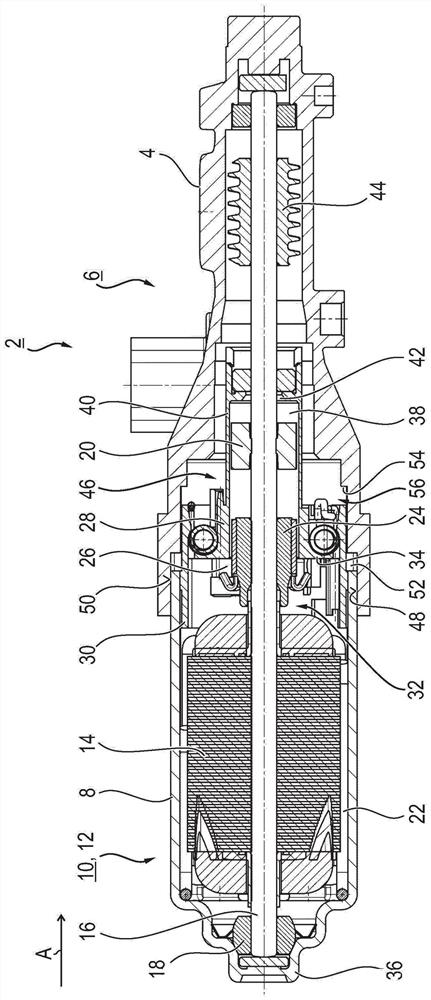

[0035] The motor housing 8 is, for example, a metal pole pot that is deep-drawn from sheet material. feels like figure 2 and image 3 As can be seen in , the motor unit 10 arranged inside the motor housing 8 comprises an electric motor 12 having a motor shaft 16 carrying a rotor or mover 14 , which is rotatably supported on a rotor-side spherical bearing 18 and in the plain bearing or sintered bearing (Sinterlager) 20 on the transmission side. Permanent magnets 22 held in a fixed position in motor housing 8 form the stator of electric motor 12 .

[0036] Between the rotor 14 and the sliding bearing 20 , a commutator with a commutator shaft (not shown in det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com