Goods shelf point rivet automatic welding device

An automatic welding and shelf technology, which is applied in the field of automatic welding equipment for shelf point rivets and welding equipment for bicycle shelves, can solve the problems of low welding efficiency, high labor intensity, and low product standardization, so as to increase production capacity, increase welding speed, Avoid the effect of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

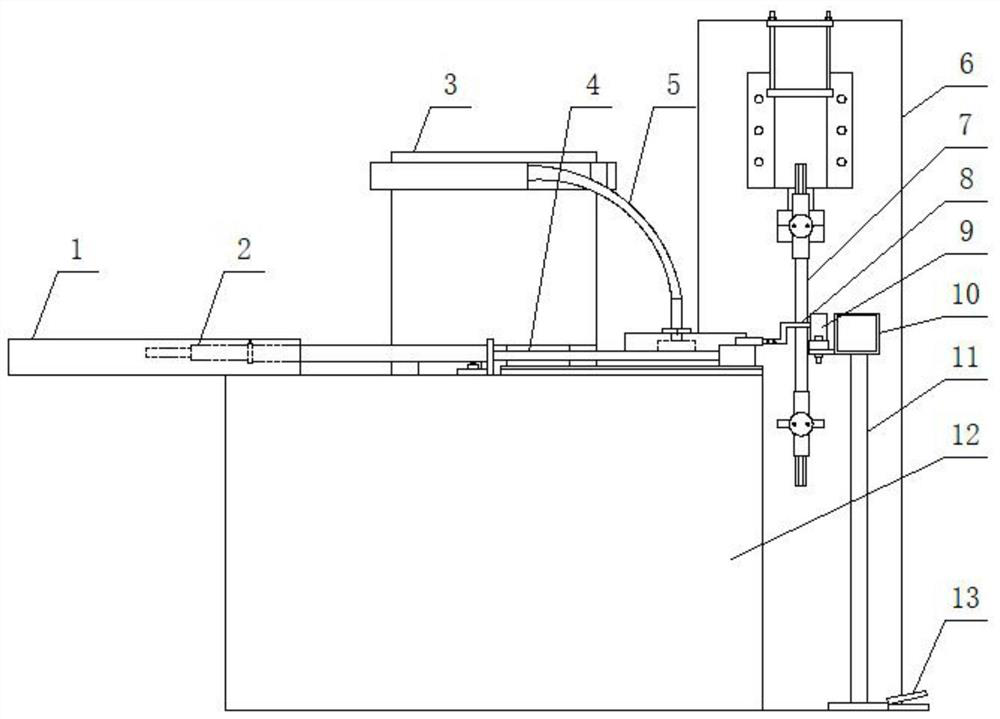

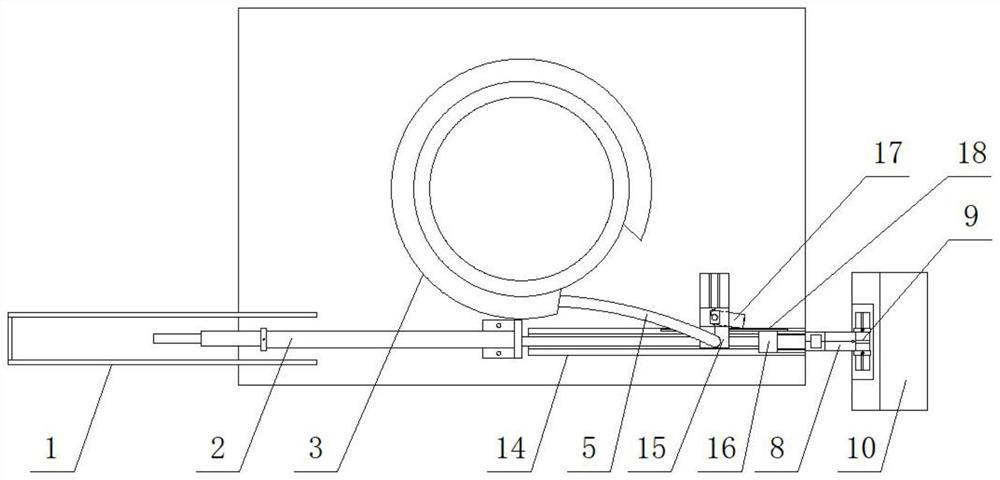

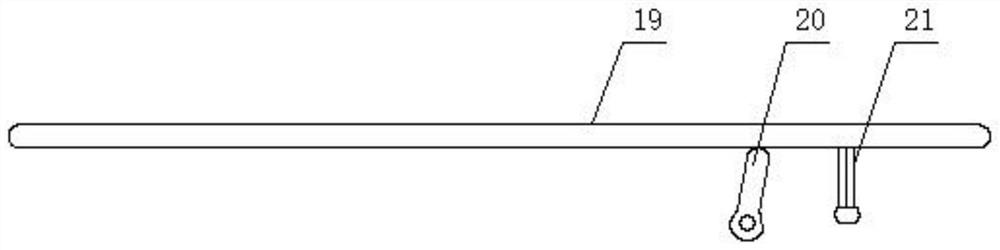

[0024] An automatic welding device for shelf point rivets, including a spot welding machine 6 controlled by a pedal 13, and its innovation is that it also includes an automatic feeding unit and a shelf limit unit, and the automatic feeding unit consists of a workbench 12, The feeding mechanism, the first pneumatic gripper 15 and the pushing and feeding mechanism are composed, the feeding mechanism is installed on the workbench, the first pneumatic gripper is arranged at the lower end of the conduit mouth of the feeding mechanism, and the described pushing and feeding mechanism Set on the front end of the feeding mechanism on the workbench, push the cylinder 2 on the feeding mechanism to push the second pneumatic gripper 8 to do telescopic mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com