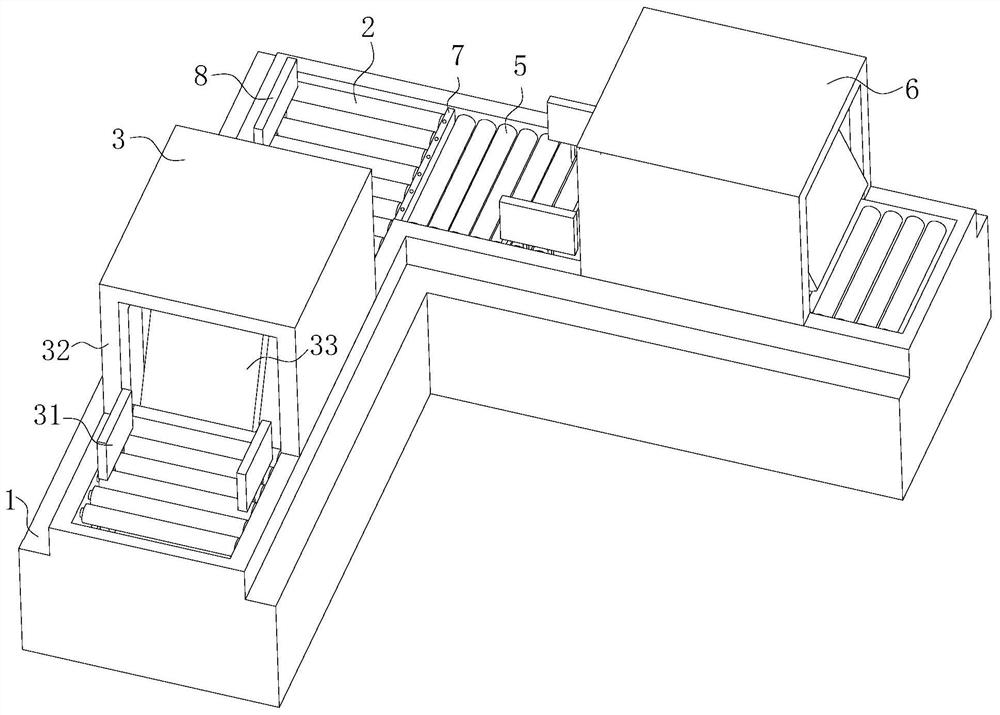

Carton packing machine

A baler and carton technology, applied in the field of balers, can solve problems such as affecting the baling effect of the baler, the packing parts of the carton are not firm enough, and the stacks of cartons are not neat enough, so as to save labor processing time, improve the packaging effect, and not easily loosen. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

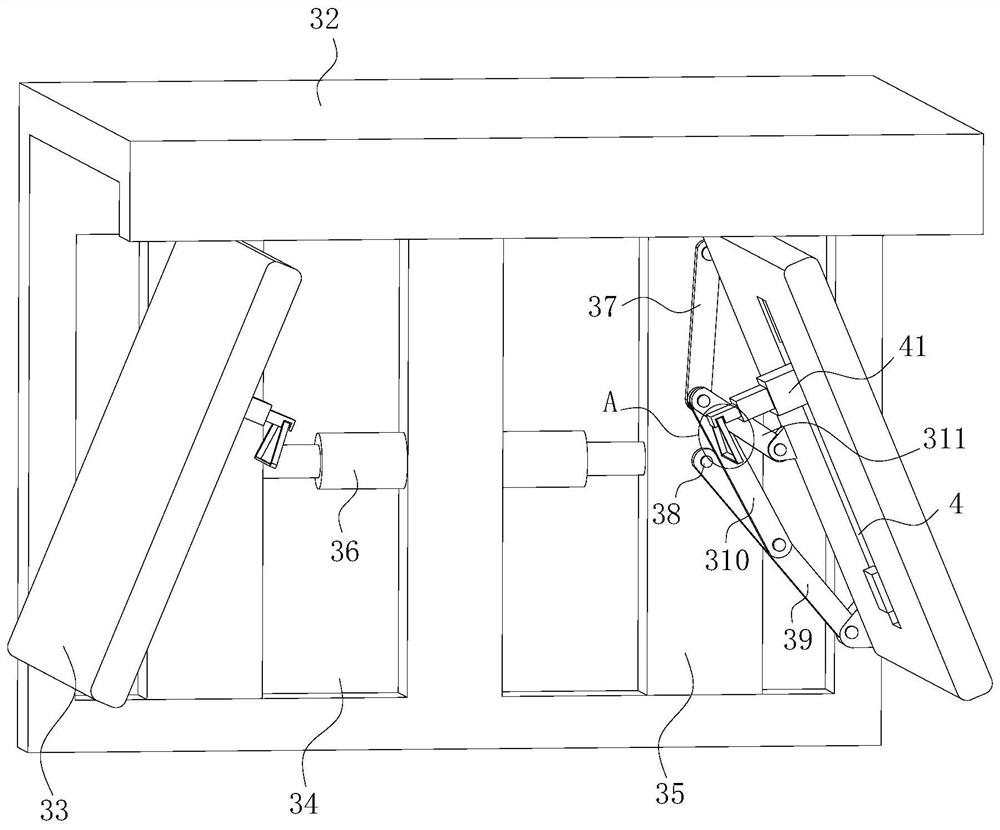

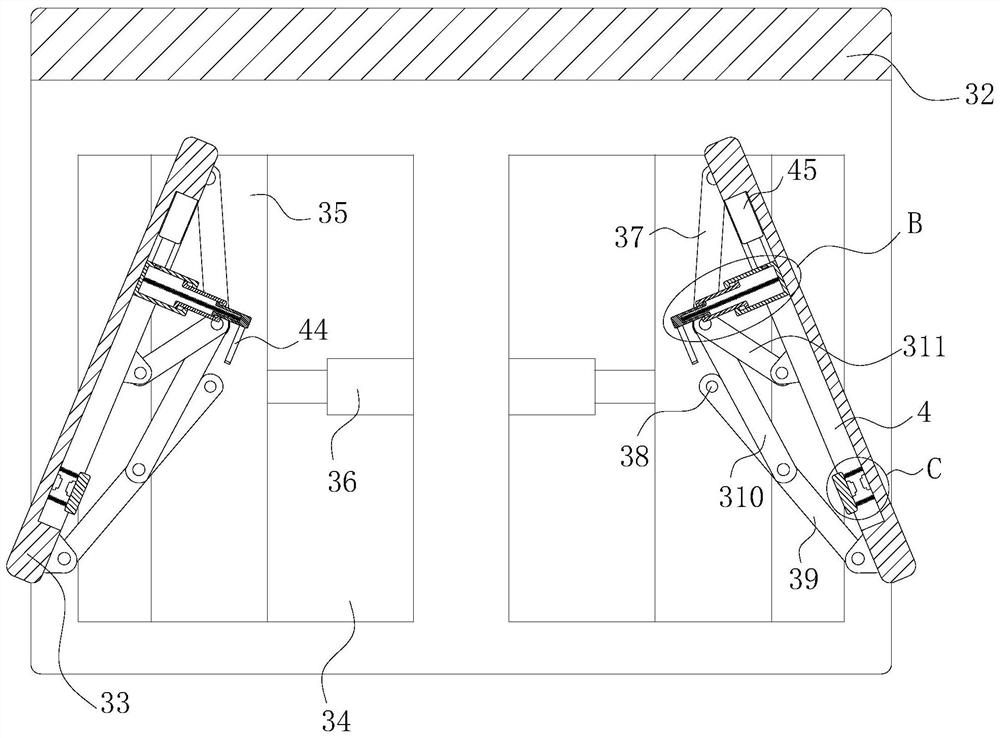

[0028] As an embodiment of the present invention, a sliding groove 4 is opened in the middle of the side of the second clapper 33 relative to the central axis of the first housing 32, and a main sleeve rod 41 is slidably connected to the sliding groove 4. , the inside of the main sleeve rod 41 is a hollow structure, a plurality of sub-set rods 42 are slidably connected to the inside of the main sleeve rod 41, and a first spring 43 is arranged between the inside of the main sleeve rod 41 and the sub-set rods 42, and One end of the separating rod 42 away from the second clapper 33 is provided with a pressing device 44; the upper surface of the main sleeve rod 41 and the inner wall of the upper end of the sliding groove 4 are fixedly connected with a second telescopic cylinder 45, and the upper surface of the main sleeve rod 41 Opening 46 is opened, and described opening 46 communicates with the inside of the second telescopic cylinder 45 and main sleeve rod 41, and control valve ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap