Mining machinery auxiliary conveying device

A mechanical auxiliary and transmission device technology, applied in the field of mining machinery, can solve problems such as slipping and fixing cannot be switched well, and achieve the effects of high degree of automation, easy movement and fixing, and various functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

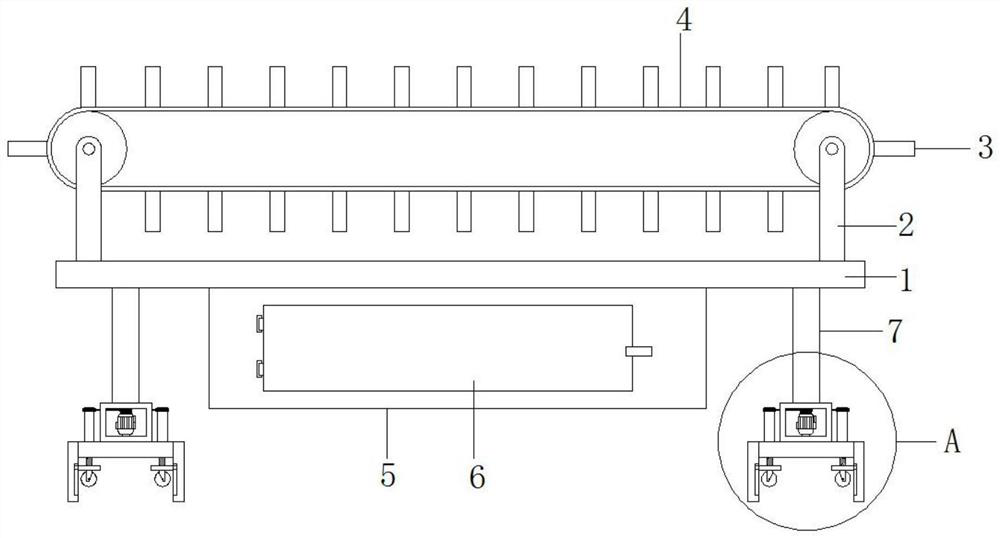

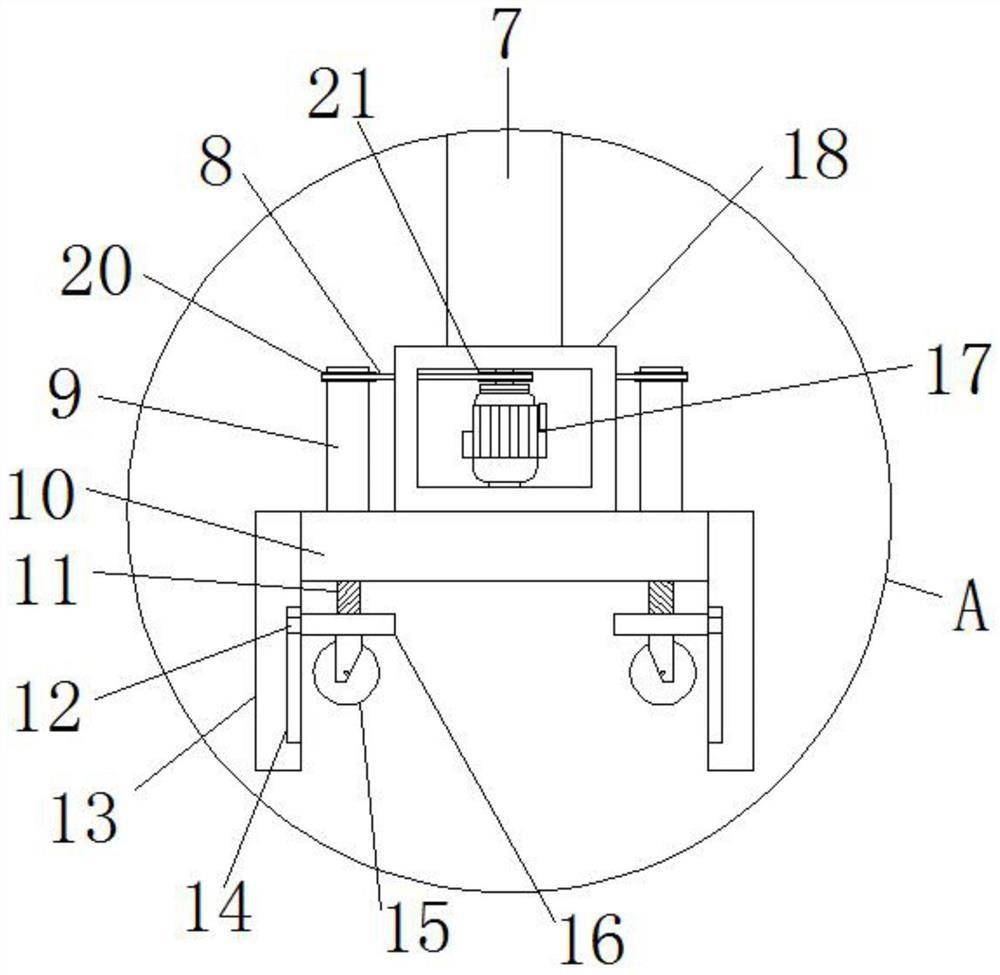

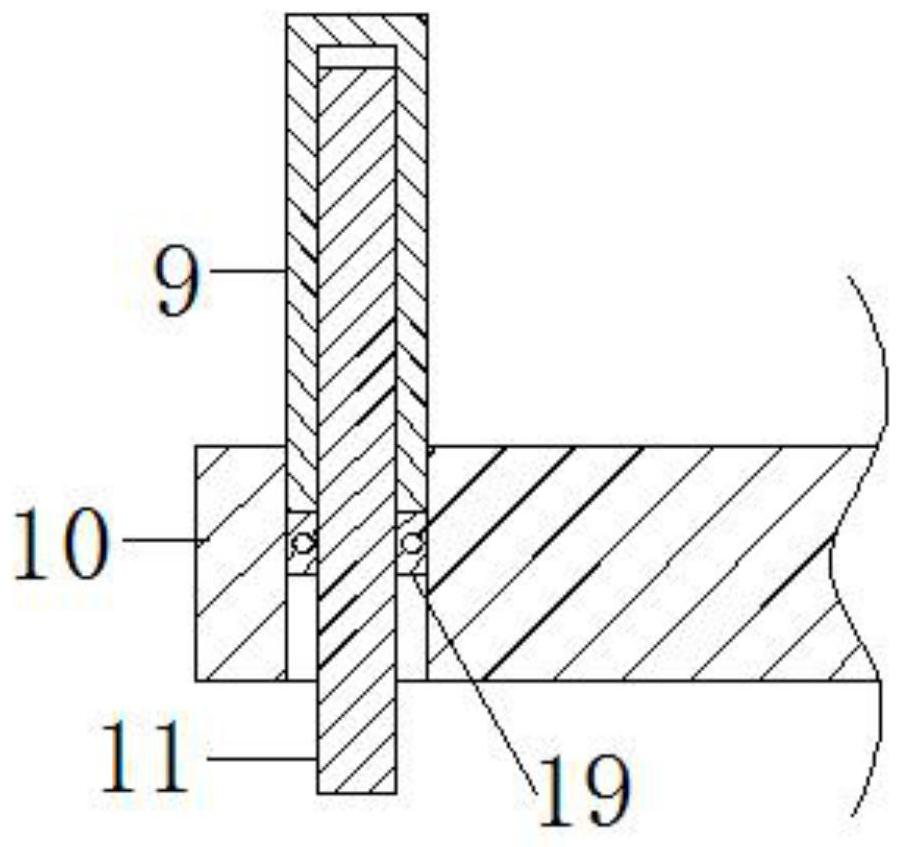

[0027] Embodiment: The present invention can be fixedly supported by the supporting side plate 13. When the present invention needs to be moved, the driving motor 17 can be started, and the driving motor 17 is driven by the first transmission wheel 20, the second transmission wheel 21 and the transmission belt 8. When the transmission shaft cylinder 9 rotates, the inner wall of the transmission shaft cylinder 9 meshes with the support screw 11, and the connecting plate 16 slides in the vertical direction through the guide slider 12 and the support side plate 13, so that the support screw 11 moves in the vertical direction, The supporting screw rod 11 moves down to drive the connecting plate 16 to move down, and then drives the universal wheel 15 to move down, and the universal wheel 15 moves down to the joint with the ground. The present invention is moved to the wheel 15. By starting the belt conveyor 4, the belt conveyor 4 works to transport the minerals put into its upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com