Stacking and conveying device for coal gangue hollow bricks

A technology for conveying devices and hollow bricks, applied in the direction of conveyor objects, transportation and packaging, object stacking, etc., can solve the problems of tilting and collapsing, poor effect, waste of manpower and time, etc., to avoid tilting and collapsing, good flexibility , high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

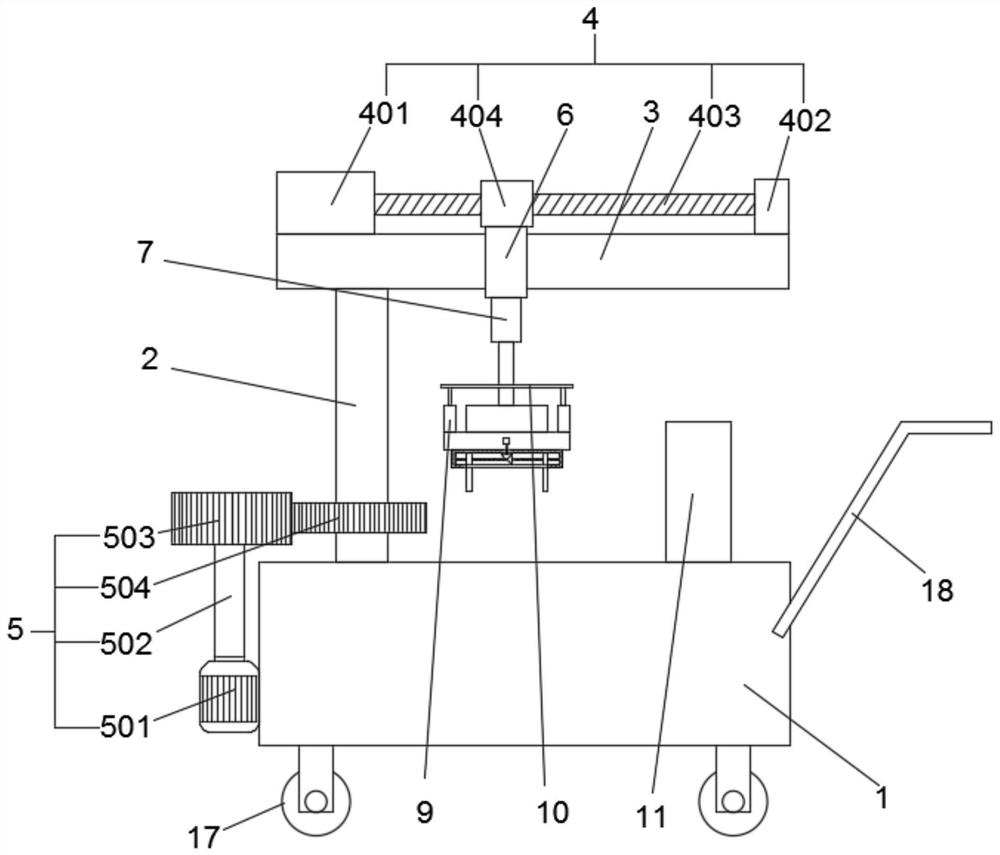

[0029] Embodiment 1: as Figure 1-5 Shown; a coal gangue hollow brick palletizing and conveying device, comprising a transport vehicle 1, the middle part of the left end of the transport vehicle 1 is rotatably equipped with a steering column 2, and the top of the steering column 2 is fixedly equipped with a bearing plate 3, and the bearing plate 3 A bracket 6 is sleeved on the outside, a cylinder 7 is fixedly installed at the bottom of the bracket 6, and a handling device is fixedly installed at the telescopic end of the cylinder 7;

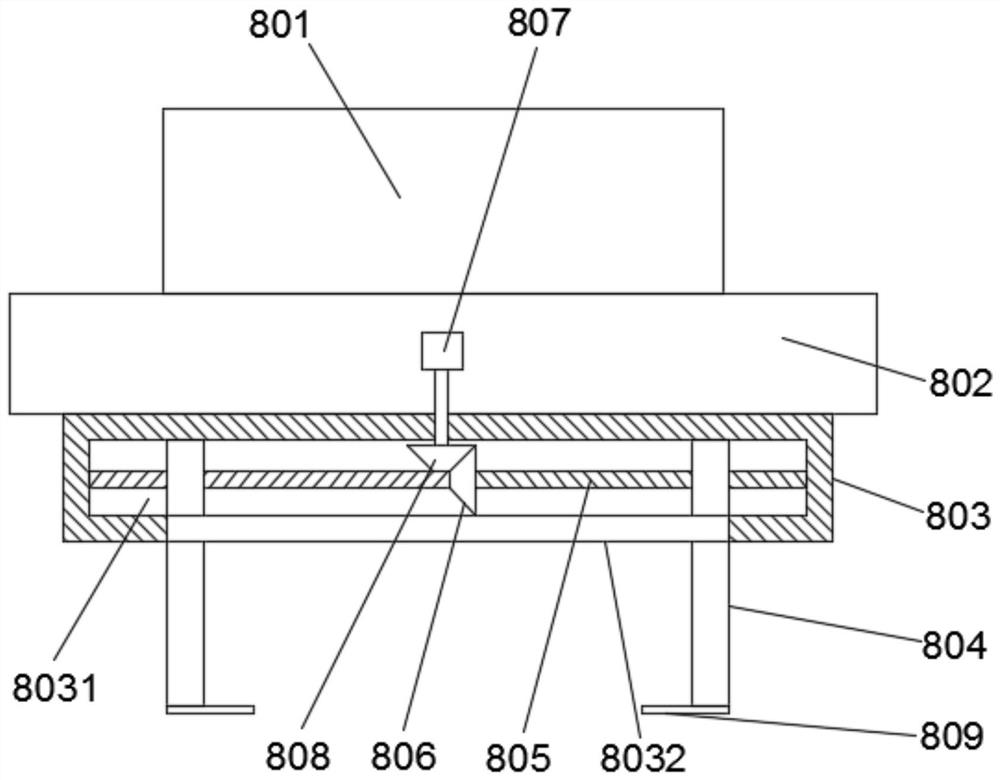

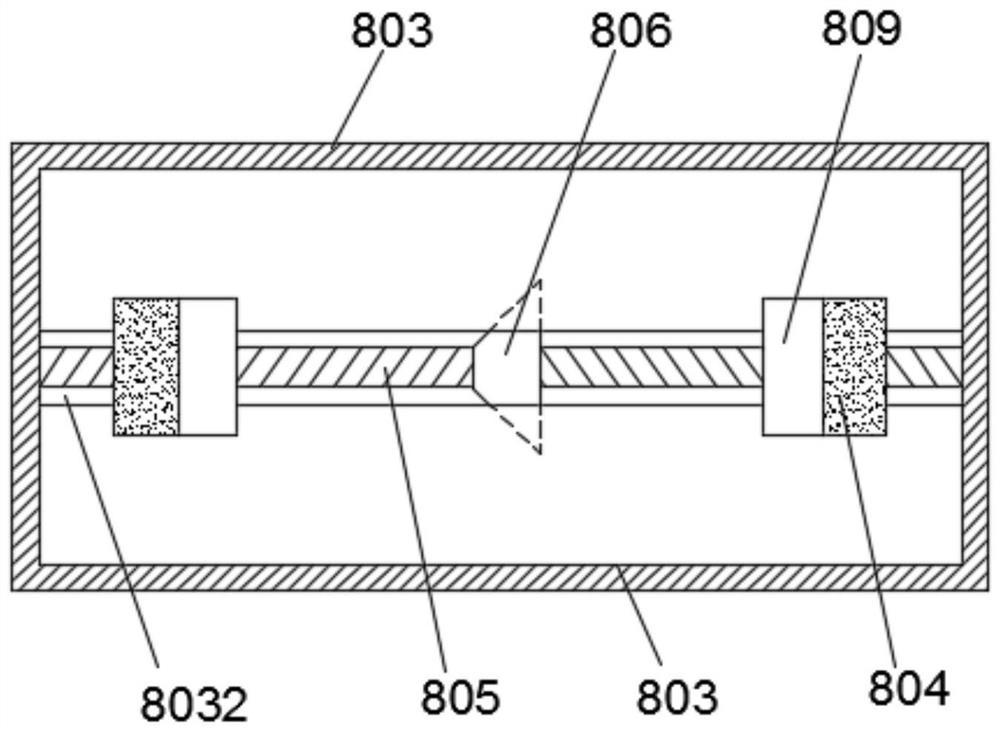

[0030] The handling device includes a connection block 801, which is fixedly installed on the telescopic end of the cylinder 7, a mounting platform 802 is fixedly installed at the bottom of the connection block 801, and an adjusting block 803 is fixedly installed at the bottom of the installation platform 802, The inside of the adjustment block 803 is provided with a cavity 8031, the bottom of the adjustment block 803 is provided with a guide gro...

Embodiment 2

[0037] Embodiment 2: as Figure 1-7 Shown; a coal gangue hollow brick palletizing and conveying device, comprising a transport vehicle 1, the middle part of the left end of the transport vehicle 1 is rotatably equipped with a steering column 2, and the top of the steering column 2 is fixedly equipped with a bearing plate 3, and the bearing plate 3 A bracket 6 is sleeved on the outside, a cylinder 7 is fixedly installed at the bottom of the bracket 6, and a handling device is fixedly installed at the telescopic end of the cylinder 7;

[0038] The handling device includes a connection block 801, which is fixedly installed on the telescopic end of the cylinder 7, a mounting platform 802 is fixedly installed at the bottom of the connection block 801, and an adjusting block 803 is fixedly installed at the bottom of the installation platform 802, The inside of the adjustment block 803 is provided with a cavity 8031, the bottom of the adjustment block 803 is provided with a guide gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com