High-frequency-response damping-adjustable semi-active shock absorber

A semi-active shock absorber, high-frequency technology, applied in the direction of shock absorber, liquid shock absorber, spring/shock absorber functional characteristics, etc., can solve the problem of passive hydraulic shock absorber adjustment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

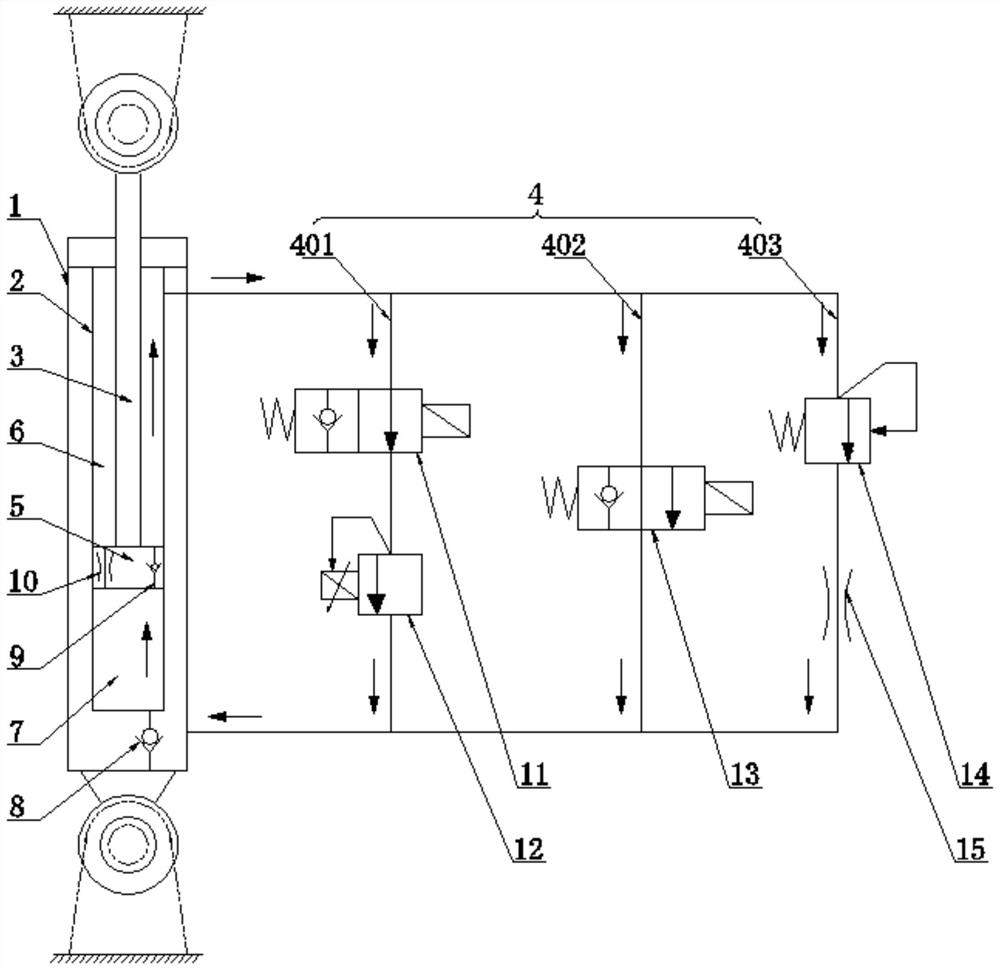

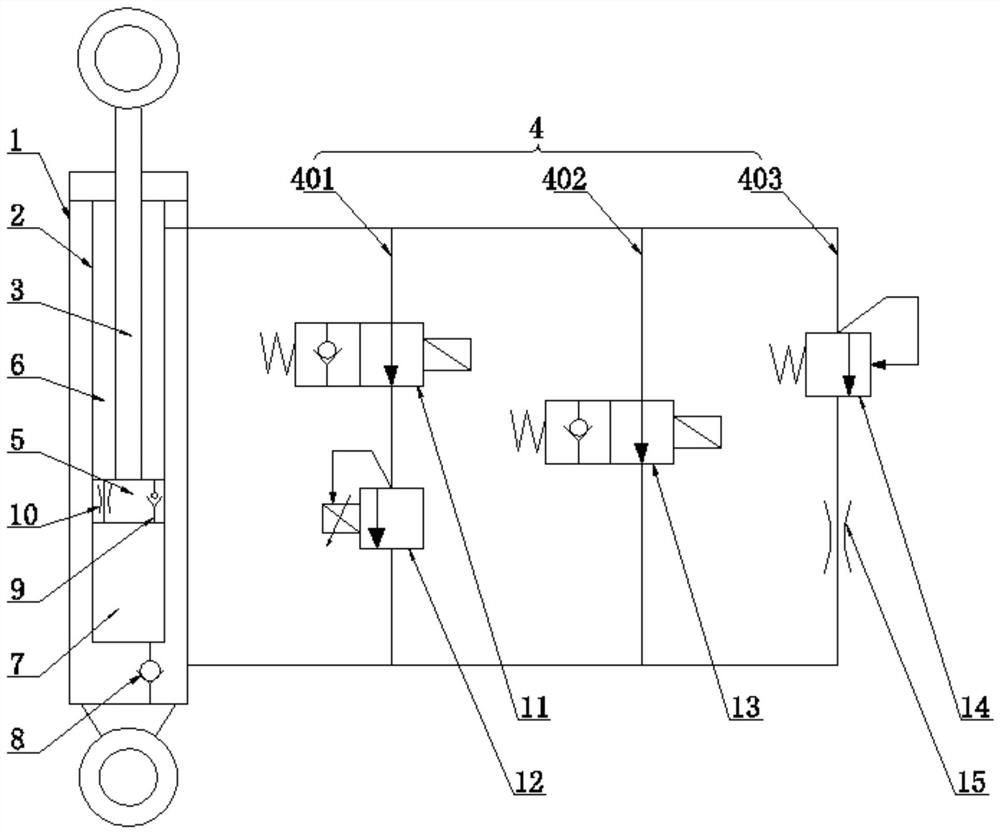

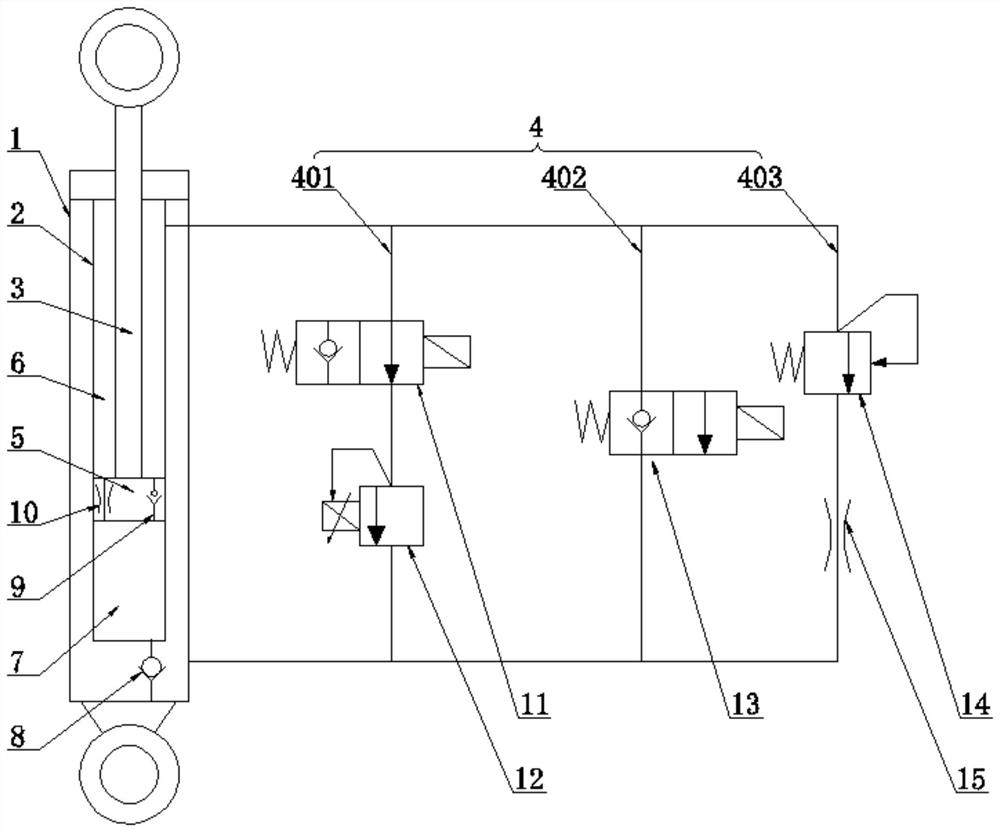

[0029] like Figure 1-9 As shown, a high-frequency response damping adjustable semi-active shock absorber includes an oil storage cylinder 1, a working cylinder 2, a piston rod 3 and a bypass oil circuit 4. The working cylinder 2 is sealed and fixed in the oil storage cylinder 1, and the piston The lower end of the rod 3 is located in the working cylinder 2 and is fixedly provided with a piston body 5. The piston body 5 is sealed and longitudinally slidably sleeved in the working cylinder 2. The piston body 5 divides the working cylinder 2 into an upper cavity 6 and a lower cavity 7. Bypass oil One end of the passage 4 is connected to the lower part of the oil storage cylinder 1, and the other end is connected to the upper part of the working cylinder 2 and is located above the piston body 5. The flow direction of the bypass oil passage 4 is that the working cylinder 2 flows to the oil storage cylinder 1, and the working cylinder 2 and the oil storage cylinder 1. A conducting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com