A heat exchange device and working method for condensing vocs gas

A heat exchange device and gas technology, applied in separation methods, gas treatment, indirect heat exchangers, etc., can solve problems such as dead ends of oil return, influence heat exchange effect, etc., and achieve the effect of reducing resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

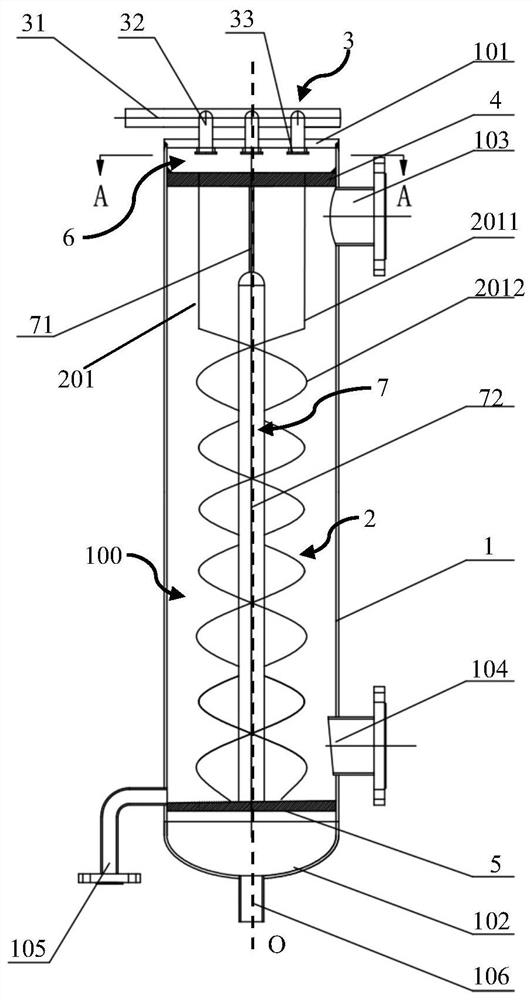

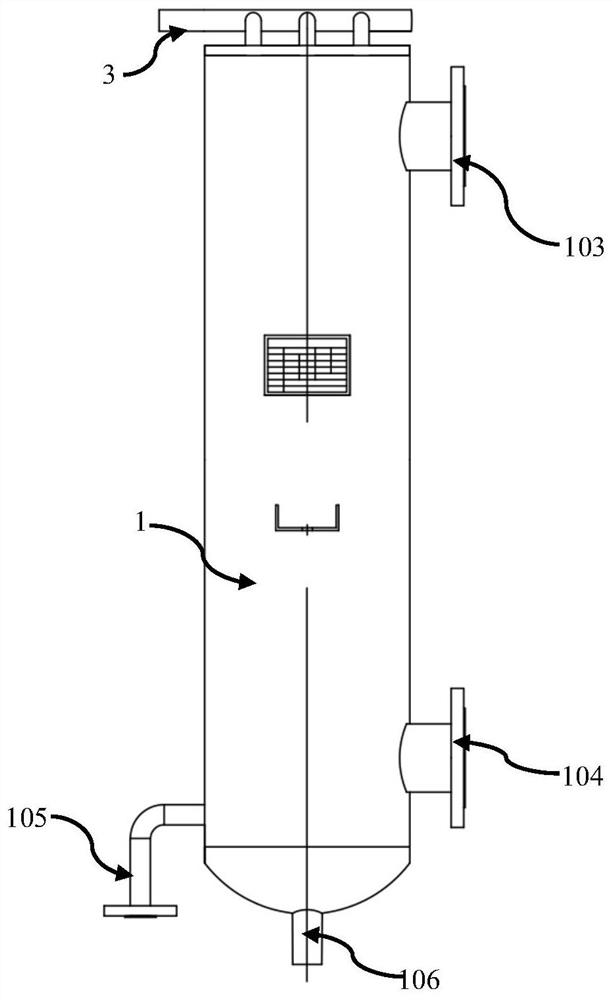

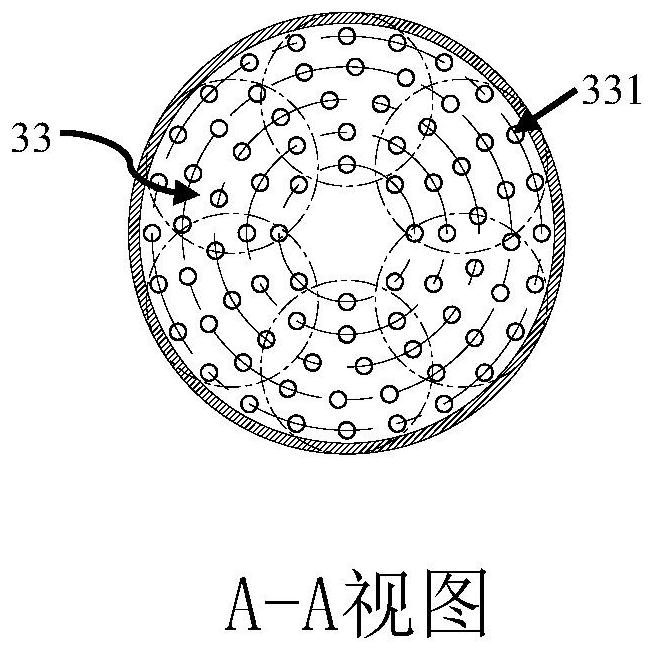

[0027] Embodiment 1: as Figure 1-3 As shown, the heat exchange device for condensing VOCs gas according to the present invention includes a vertically arranged shell 1 and a heat exchange mechanism 2 arranged in the shell 1, and the heat exchange mechanism 2 is in the shell 1 along the Extending in the direction of the longitudinal center line O; the upper end of the shell 1 is provided with a flow equalizer 3 for evenly feeding the refrigerant into the heat exchange tube 2, and the upper tube plate 4 and the lower tube plate 4 for fixing the heat exchange tube 2 are provided in the shell 1 A heat exchange chamber 100 is formed between the tube sheet 5 , the upper tube sheet 4 and the lower tube sheet 5 .

[0028] The casing 1 is a cylindrical structure in this embodiment. For example, in a specific application, the casing 1 is made of stainless steel 316L. The heat exchange mechanism 2 is located inside the shell, and the two ends of the heat exchange mechanism 2 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com