Integrated straw processing system suitable for straw recycling

A processing system and straw technology, applied in the field of straw processing, can solve the problems of easy dispersal, simple structure, unable to form an integrated processing system, etc., and achieve the effects of convenient transportation, convenient sorting and handling, and realizing integrated processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

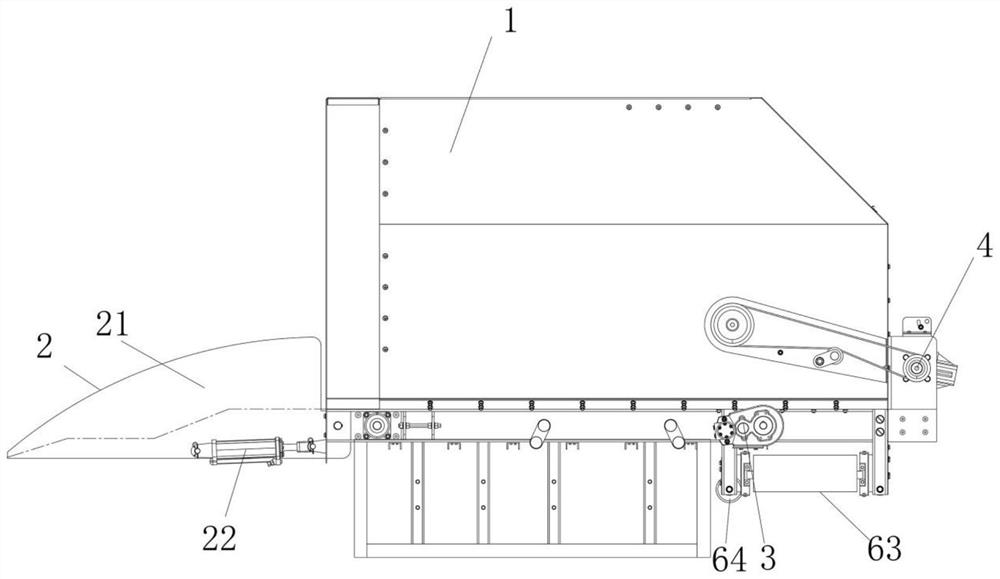

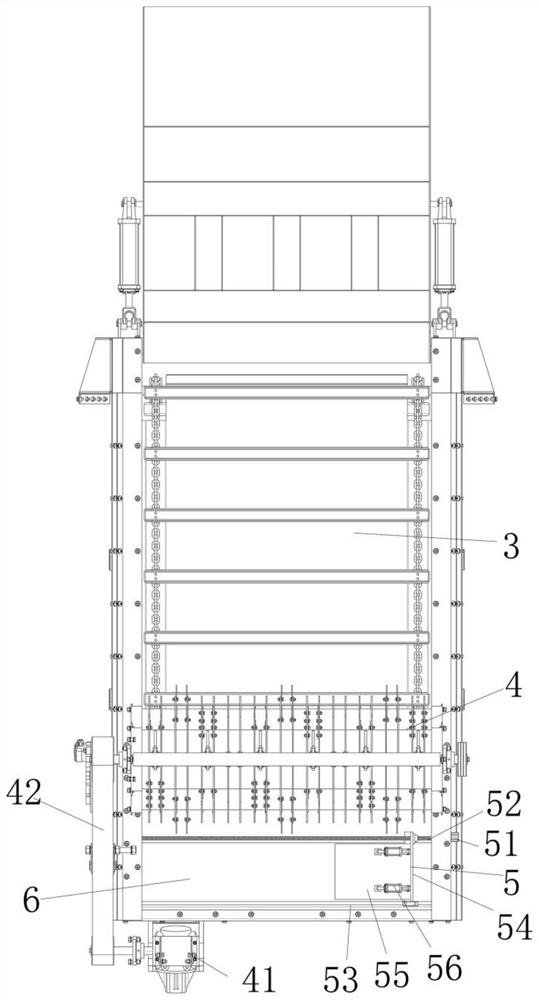

[0030] Such as figure 1 As shown, an integrated straw processing system suitable for straw reuse includes:

[0031] The frame includes a base, two side panels arranged on the base, and a back panel connecting the two side panels;

[0032] The feeding module is arranged at the front end of the frame and is used to feed the straw into the frame;

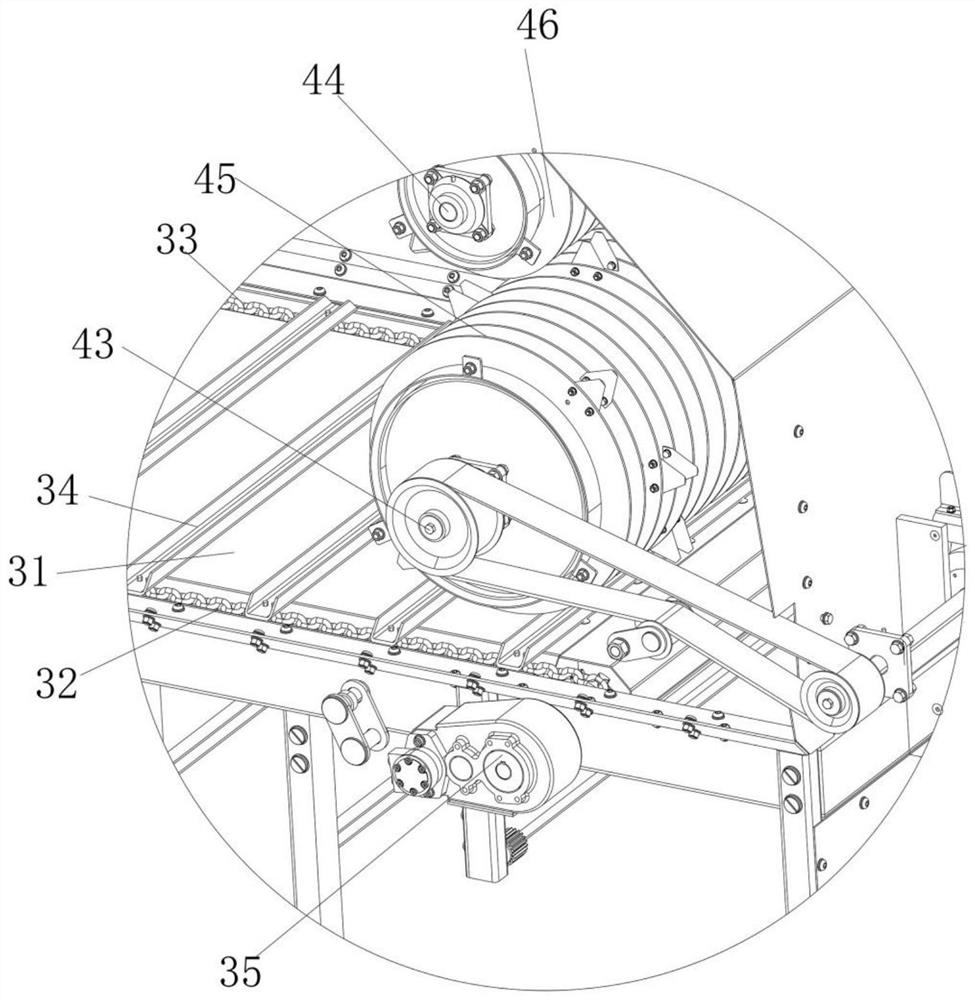

[0033] The conveying module is arranged at the bottom of the two side plates, and is used to transport the straw to the cutting module;

[0034] The cutting module is arranged in the frame and is used for chopping the straw;

[0035] The baling module is arranged on the rear side of the cutting module, and is used for pressing the chopped straw into bales;

[0036] The discharging module is arranged under the baling module, and is used to send out the baled straw;

[0037] The feed module includes a swash plate and a first telescopic cylinder, the swash plate is rotatably arranged at the rear bottom of the frame, one end of the fir...

Embodiment 2

[0043] Embodiment 2. This embodiment is a further description of the above-mentioned embodiment. It should be understood that this embodiment includes all the above-mentioned technical features and further detailed description:

[0044] The traditional way of straw recycling is mainly incineration, which not only pollutes the air environment, but also affects traffic safety. With the emphasis on and development of green planting, the use of mechanized methods to pick up and bale straw can not only greatly reduce the labor intensity of farmers and save labor, but also can be used for household and large-scale breeding, papermaking, straw power generation and Alcohol production provides more feed and production raw materials, and is also convenient for transportation and storage. The straw has been comprehensively utilized and the environment has been effectively protected.

[0045] An integrated straw processing system suitable for straw reuse, including:

[0046] The frame in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com