Dust collector with wind dust raising device and using method

A technology for vacuum cleaners and dust collectors, applied in the directions of vacuum cleaners, suction nozzles, applications, etc., can solve the problems of dust accumulation that cannot be sucked up by airflow, unable to clean up dust accumulation, and increase repetitive labor, so as to increase efficiency and improve Wind speed, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

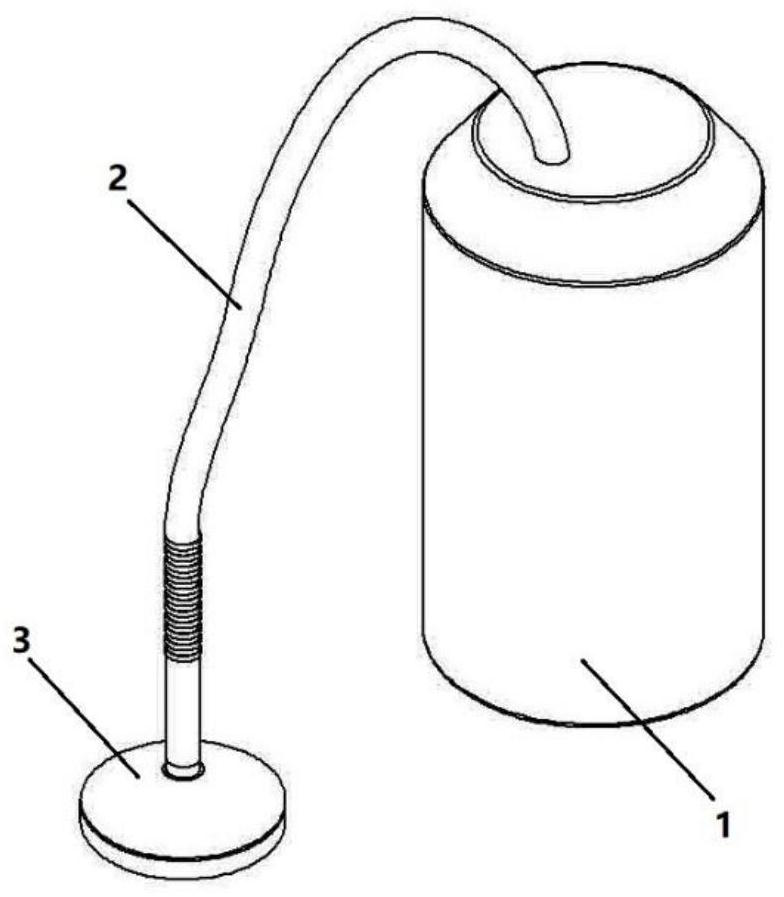

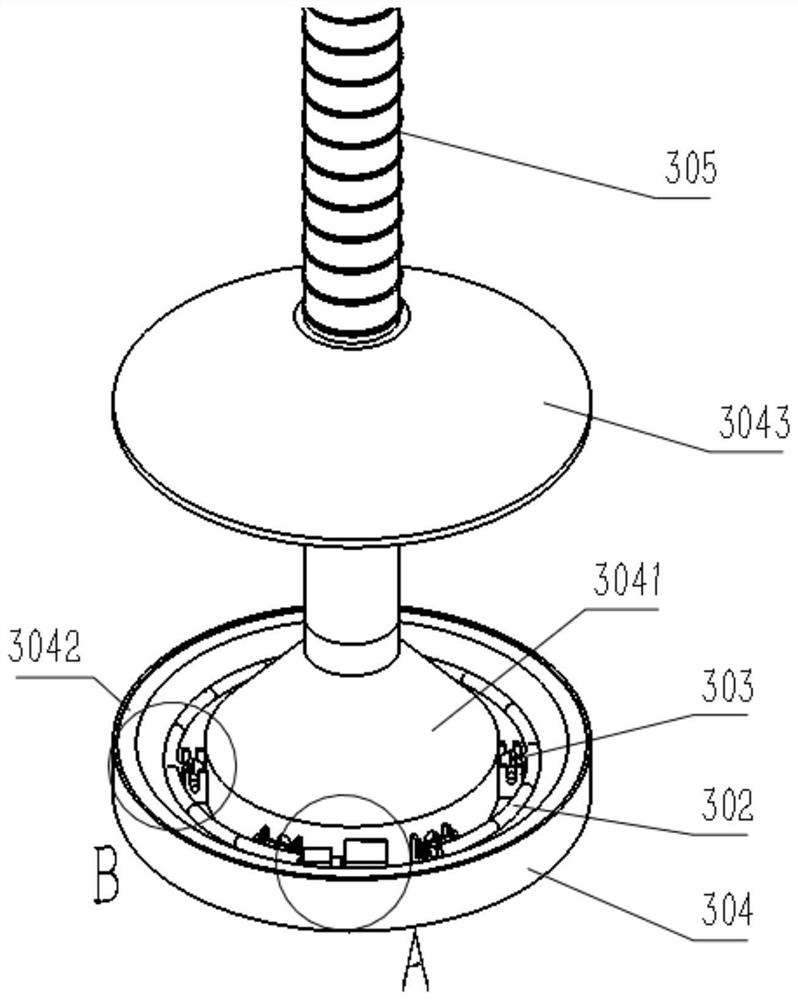

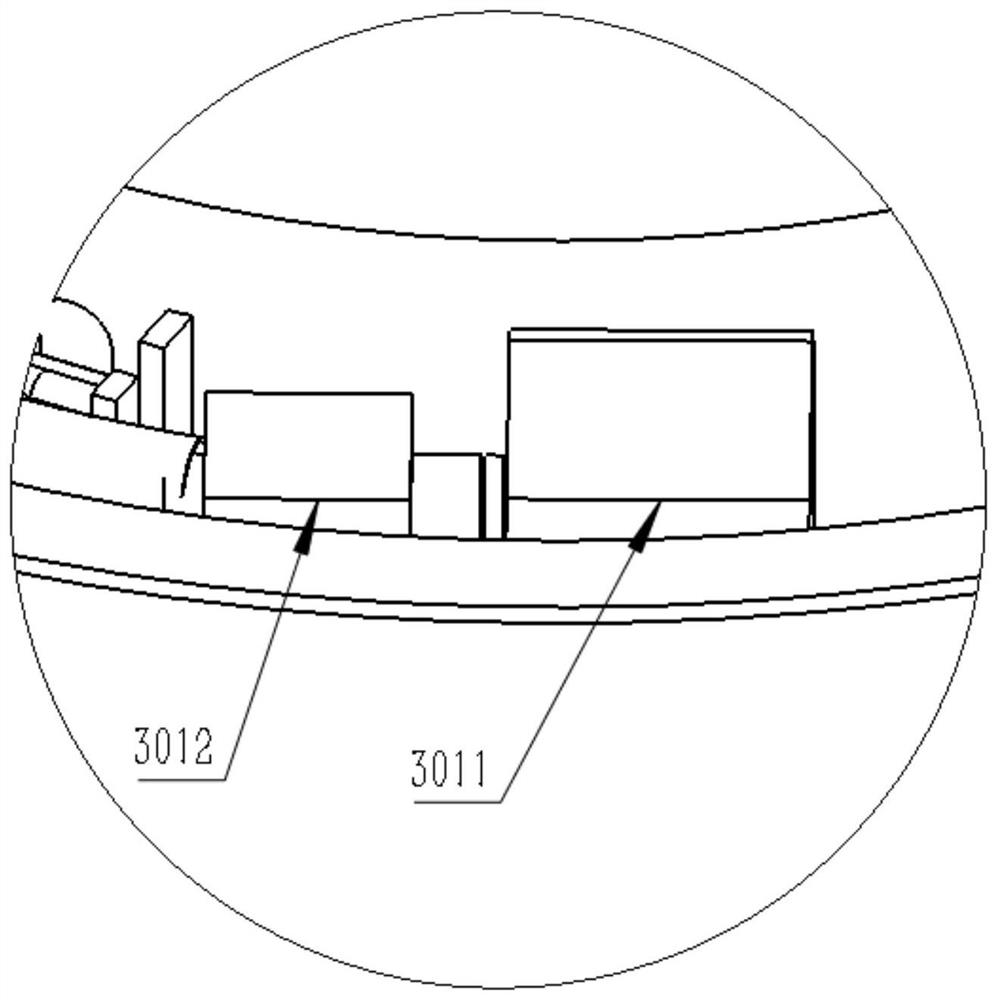

[0033]Embodiment: ReferenceFigures 1 to 7A vacuum cleaner with a fan, including a vacuum cleaner body 1 and a vacuum cleaner 2, and the vacuum cleaner conduit 2 is connected to the vacuum cleaner body 1, and the vacuum cleaner pipe 2 is connected to the dust collector 3, the dust collector 3, the dust collector 3 Contains the air supply vehicle 301, the wind line 302, and the jet mechanism 303, the air supply mechanism 301 includes a fan 3011 and a main pipeline valve 3012 connected to the fan 3011, the wind line 302 comprising The duct 3021 and the conduit connector 3022, the conduit connector 3022 is disposed at both ends of the duct 3021, the injection mechanism 303 including nozzle 3031, and the main pipeline valve 3012 is connected to the conduit connector 3022, the nozzle 3031 The pipe connector 3022 is connected to the duct 3021; the diameter of the nozzle 3031 is smaller than the inlet diameter.

[0034]Further, the fan 3011 is a centrifugal pressure fan.

[0035]Further, the ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com