Double turret turning center with high precision and stable angle control

A technology of angle control and turning center, which is applied in the direction of manufacturing tools, tool holders, metal processing machinery parts, etc., can solve the problems of difficult control of the operating range, large error range of monitoring results, and uncontrollable accuracy, so as to save manual monitoring and replacement. The steps of the knife, the highly precise control of the adjustment angle, and the effect of improving the efficiency and quality of turning processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

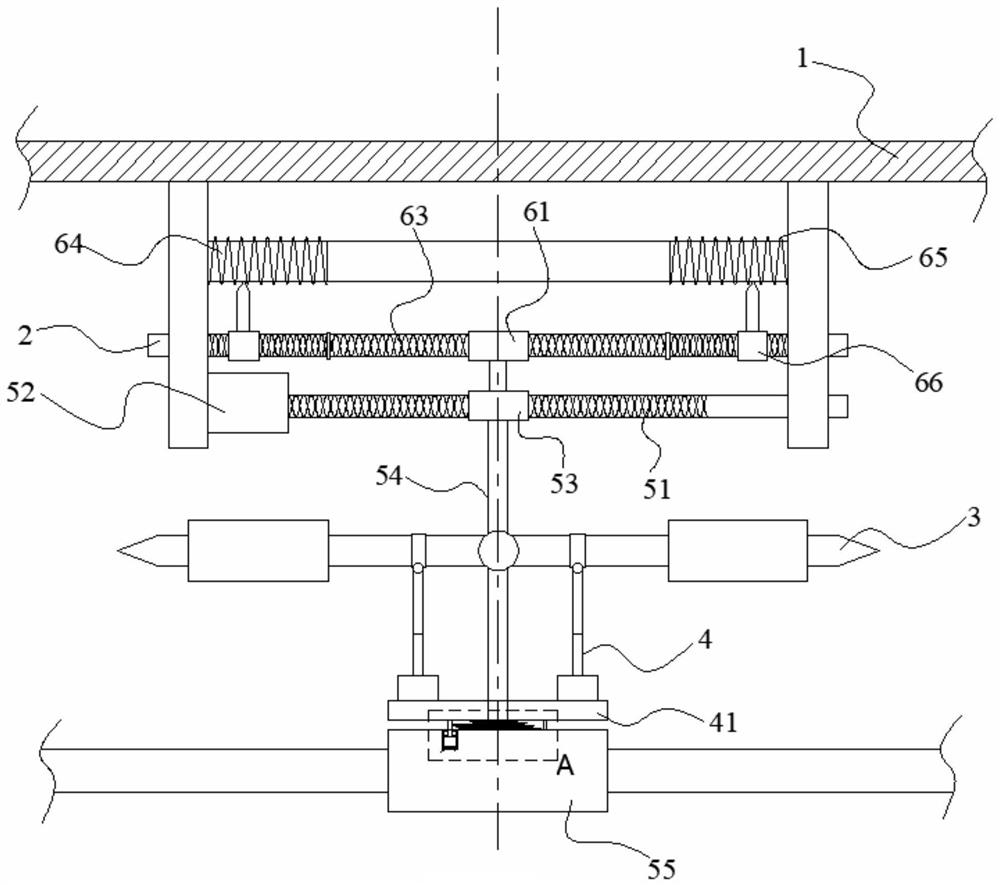

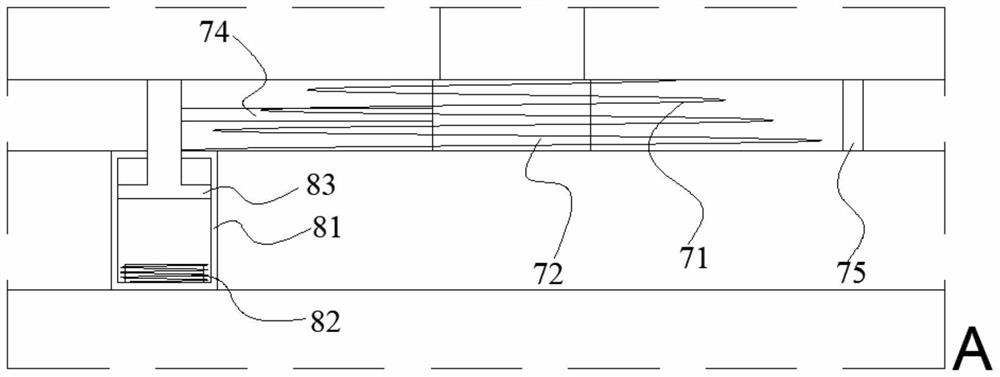

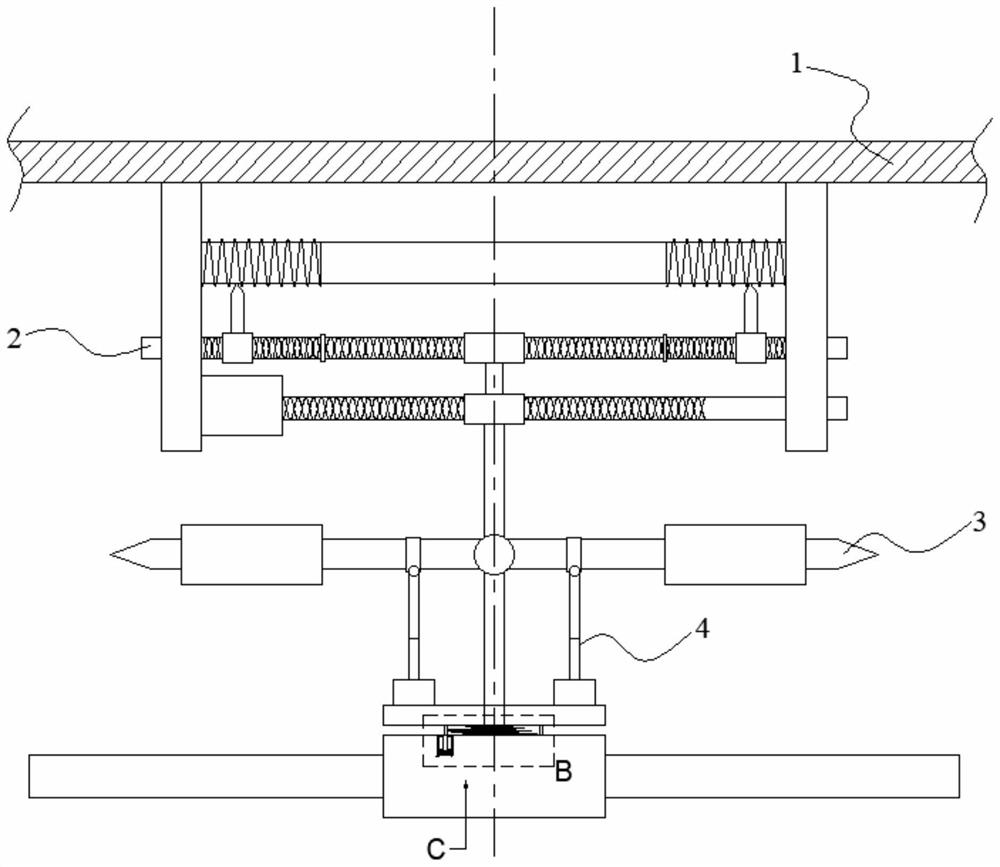

[0033] See Figure 1-10 , The present invention provides a technical solution: a high-precision steady angle controlled double-knife tower wheel, a frame 1, a mold mechanism 2, a tool 3, and an angle control mechanism 4, the feed mechanism 2 is fitted to the rack 1, One end of the knife mechanism 2 is fixedly connected to the frame 1, and the other end of the feed mechanism 2 is slidably connected to the frame 1, the one end of the tool 3 is connected to the feed mechanism 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com