Wood deburring and mortise and tenon hole forming device

A technology for deburring and deburring mechanisms, which is applied in the direction of grinding drive devices, grinding machines, fixed drilling machines, etc. It can solve the problems that cannot be spliced with mortise and tenon structures, and achieve the effect of saving manpower and consistent moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

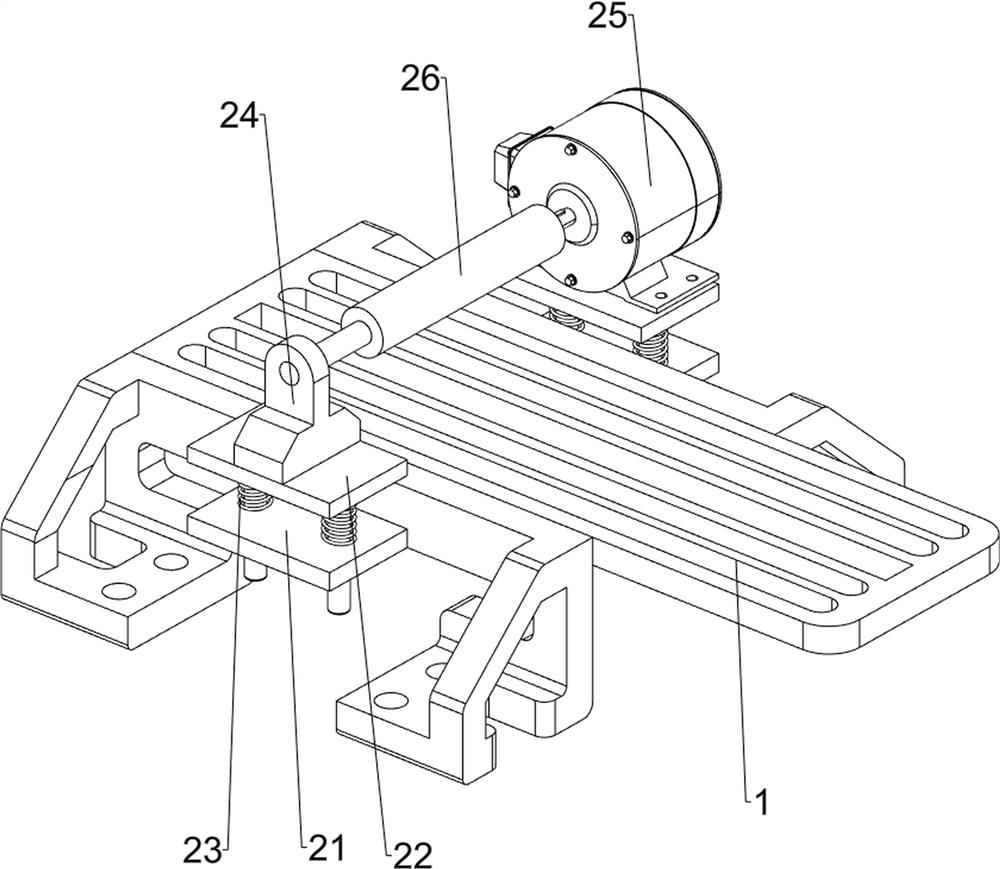

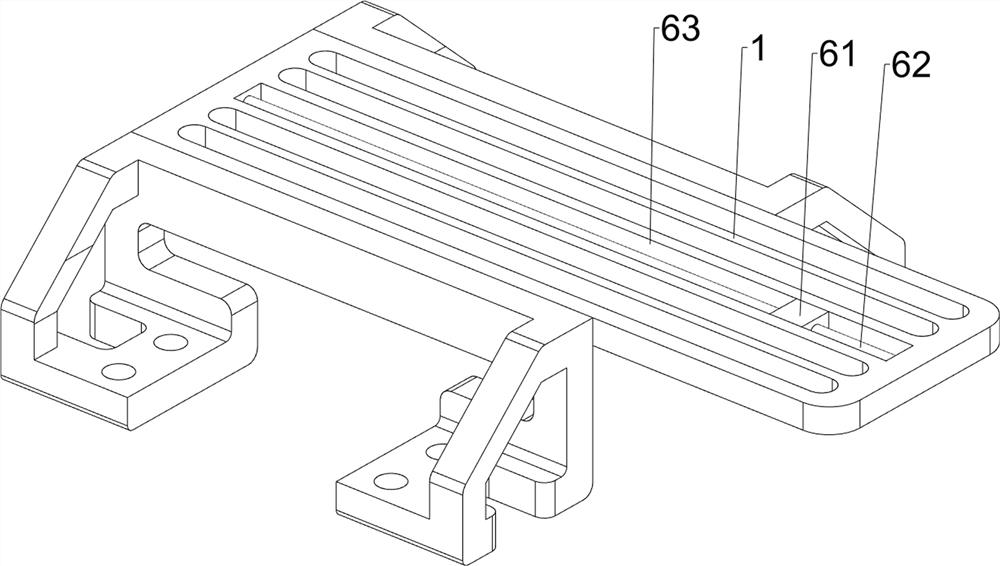

[0058] A wood deburring device for opening tenon and tenon holes, such as figure 1 As shown, it includes a mounting frame 1 , a deburring mechanism 2 and a punching mechanism 3 , the top of the mounting frame 1 is provided with a deburring mechanism 2 , and the deburring mechanism 2 is provided with a punching mechanism 3 .

[0059] Such as figure 2 As shown, the deburring mechanism 2 includes a first mounting plate 21, a second mounting plate 22, a first spring 23, a mounting block 24, a motor 25 and a grinding wheel 26, and the middle part of the front and rear sides of the mounting frame 1 is provided with a first mounting plate 21. A second mounting plate 22 is slidingly provided on the first mounting plate 21. Two first springs 23 are connected between the bottom of the second mounting plate 22 on the front and rear sides and the first mounting plate 21. Two mounting plate 22 tops are provided with mounting block 24, and mounting block 24 upper side rotations are provid...

Embodiment 2

[0063] On the basis of Example 1, such as Figure 4 As shown, a clamping mechanism 4 is also included, and the clamping mechanism 4 includes a placement plate 42, a first clamping plate 43, a second clamping plate 44, a first guide rod 45, a second spring 46 and a screw rod 47, and the mounting bracket 1 The top is placed with a placement plate 42, the left and right sides of the top of the placement plate 42 are provided with a first clamp 43, the first clamp 43 is provided with a first guide rod 45 on both sides, the first guide rod 45 on the left and right sides A second clamping plate 44 is slidably connected between them, two second springs 46 are connected between the second clamping plate 44 and the first clamping plate 43 , and a screw rod 47 is screwed on the right first clamping plate 43 .

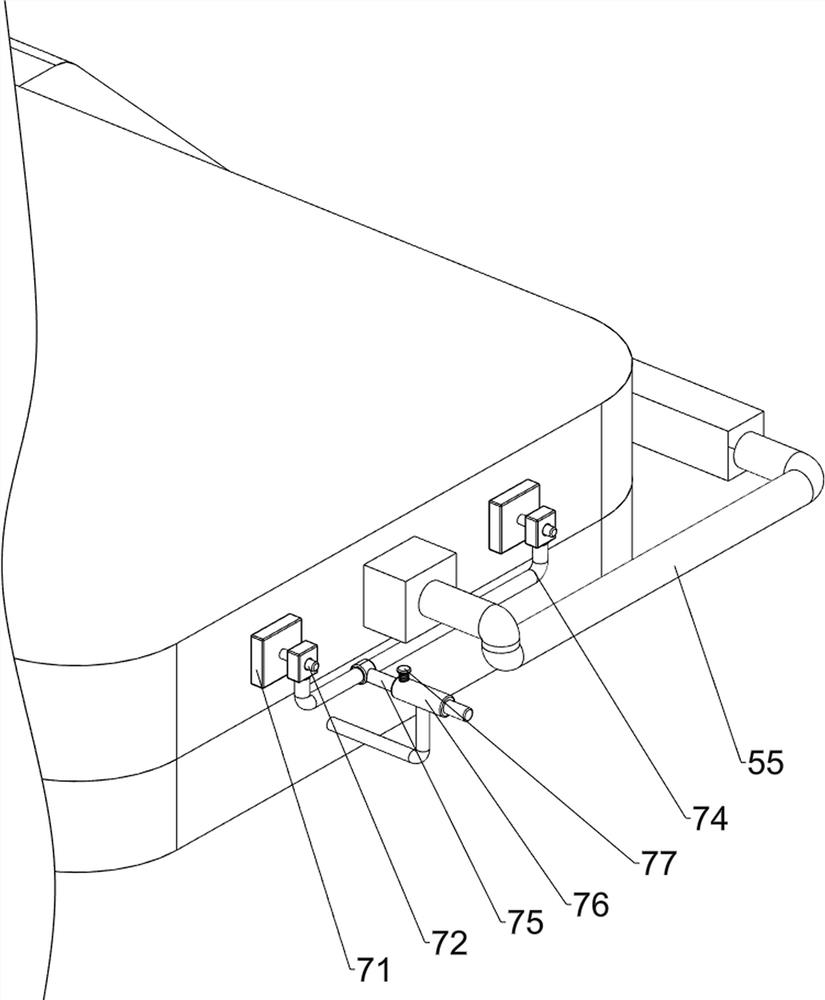

[0064] Such as Figure 5 As shown, a driving mechanism 5 is also included, and the driving mechanism 5 includes a guide rail 51, a second rack 52, a second guide rod 53, a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com