Totally-enclosed battery dismounting equipment and method thereof

A fully enclosed, battery technology, applied in manipulators, manufacturing tools, etc., can solve problems such as reducing work efficiency, and achieve the effect of improving work efficiency, reducing operating steps, and reducing the possibility of explosion or fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

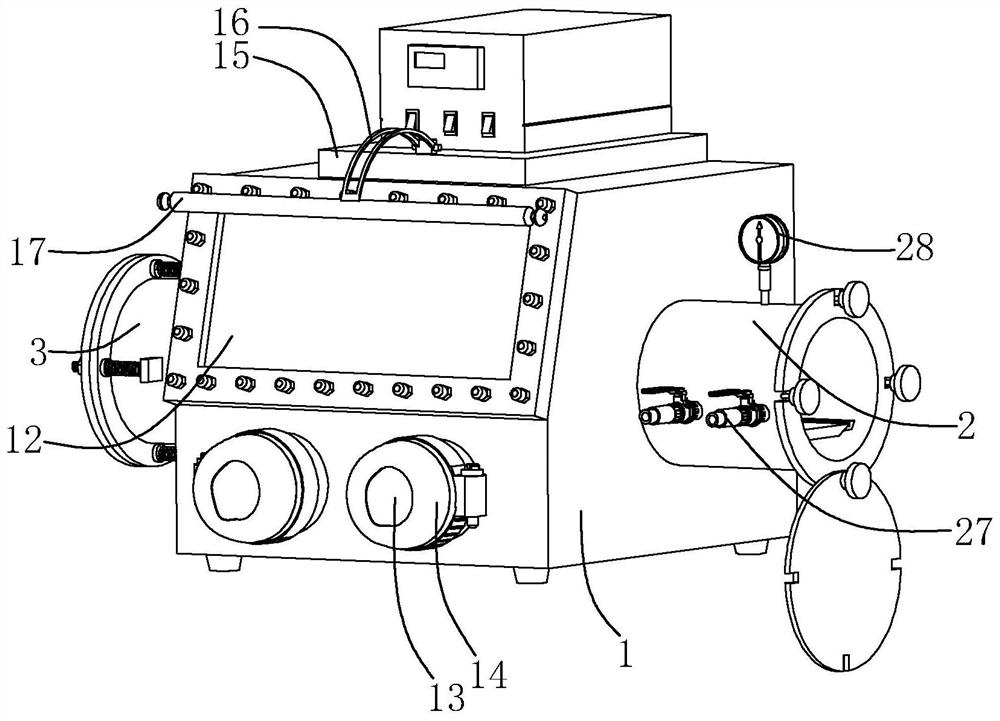

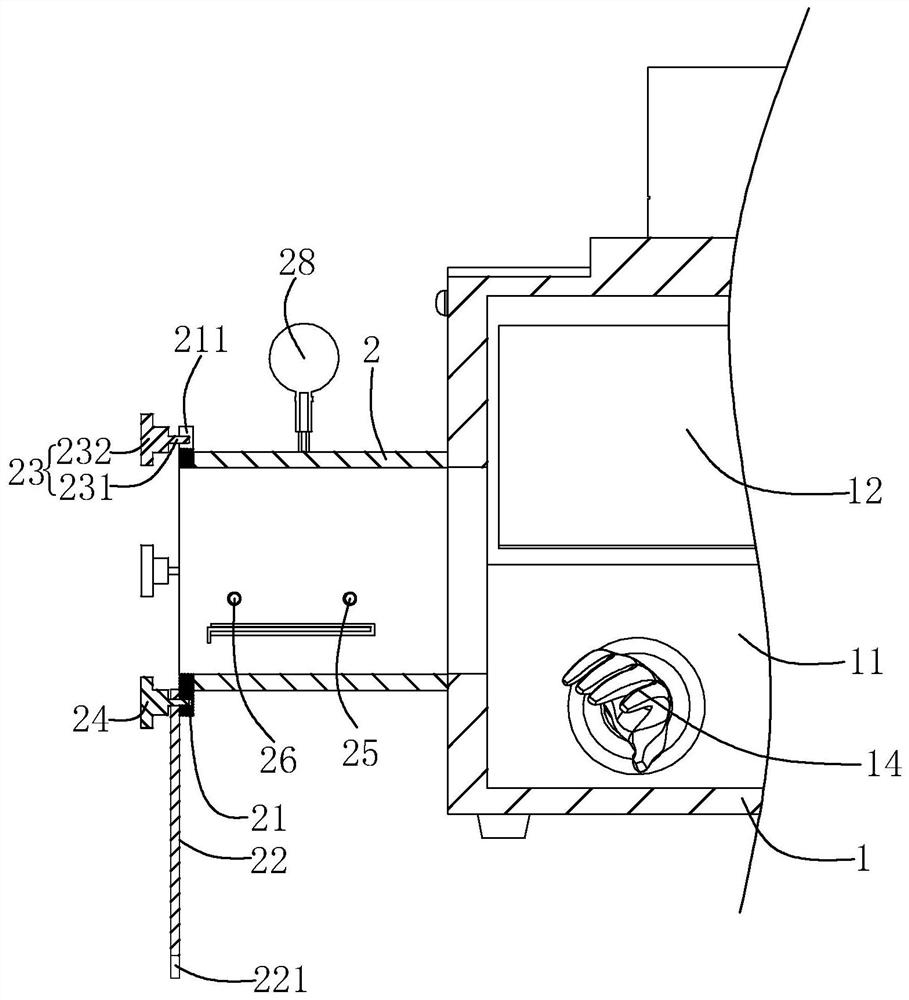

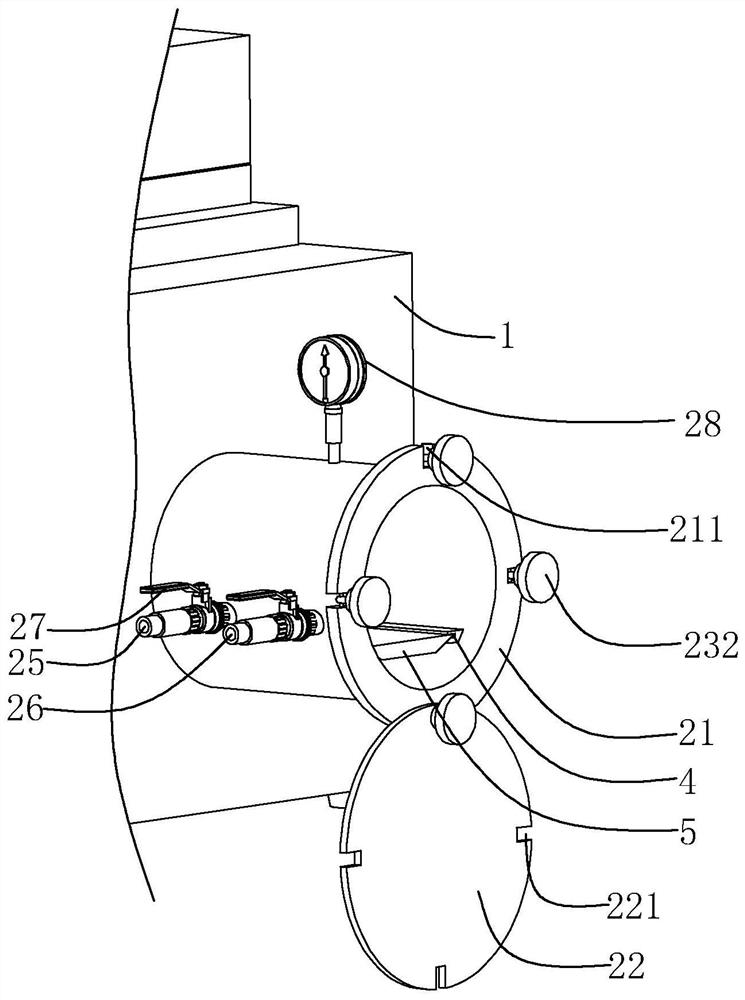

[0047] Such as figure 1 and figure 2 As shown, it is a battery fully enclosed and dismantling device disclosed in the present invention, which includes a box body 1 with an operating chamber 11 inside. The two operating ports 13 connected to the operating chamber 11 are equipped with explosion-proof glass 12 at the opening of the viewing hole, so that it is convenient to observe the operating conditions in the operating chamber 11 more clearly; the two operating ports 13 are arranged near the operator. On one side and directly below the explosion-proof glass 12, the two operation ports 13 are fixed with a long glove 14 through a clamp, and the sleeve mouth of the long glove 14 is installed on the operation port 13 through a clamp, and the other end faces the operation The cavity of the cavity 11 extends, which can protect the hands of the operator when dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com