Rounding device for cable sheath

A sheath and cable technology, which is applied in the field of cable sheath rounding devices, can solve the problems of no cylindrical box suction backflow, inability to save water resources, and inability to accelerate the cooling and shaping of the sheath, so as to save water Resources, accelerated cooling and shaping, and the effect of ensuring rounding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

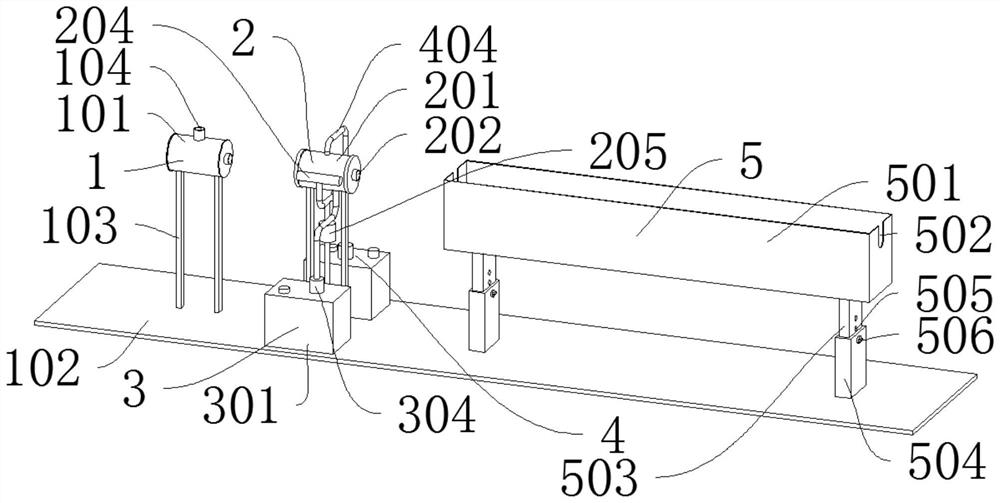

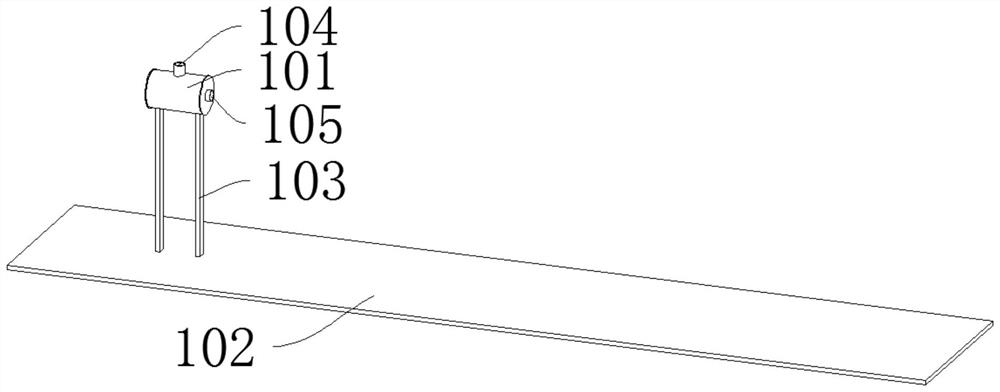

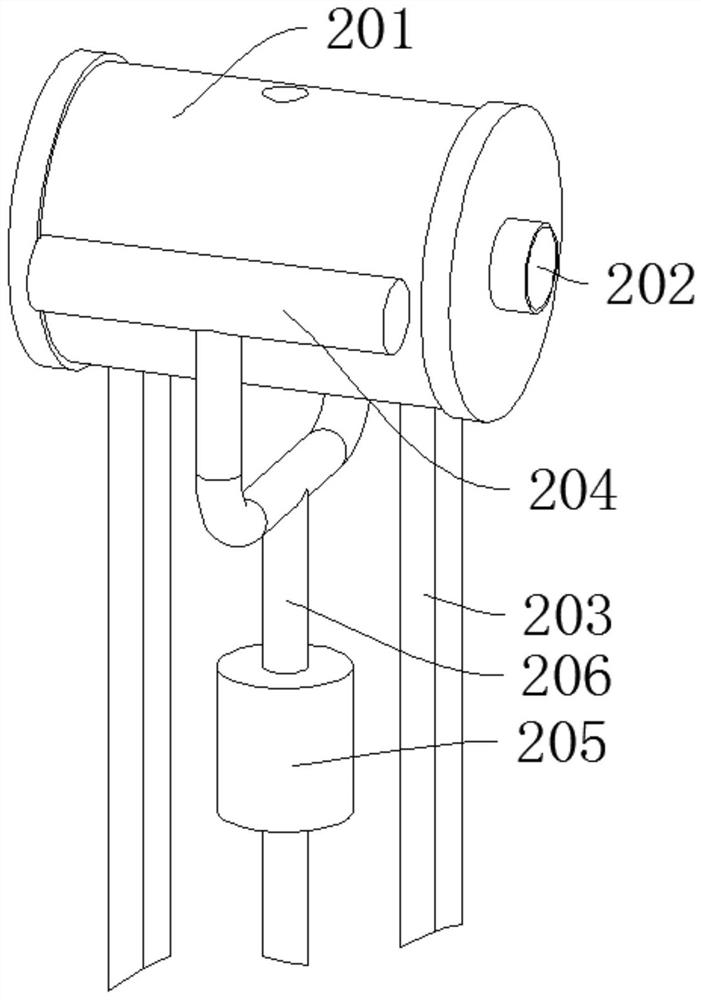

[0043] Such as Figure 1-Figure 7As shown, a rounding device for cable sheath includes a host device 1 for cable sheath injection molding, and also includes a rounding shaping device 2 for cable sheathing. The shaping device 2 is installed below There is a water tank device 3 for holding cooling water, an auxiliary tank device 4 for generating vacuum is arranged behind the water tank device 3, and a cooling device 5 for cooling the cable sheath is arranged on one side of the shaping device 2; the host device 1 includes a main body 101, a first outrigger 103 is arranged under the main body 101, a bottom plate 102 is arranged under the first outrigger 103, an injection pipe 104 is arranged on the top of the main body 101, and two inlets and outlets 105 are symmetrically installed at both ends of the main body 101; The device 2 includes a cylindrical box 201. A sizing sleeve 202 is installed in the middle of the cylindrical box 201. The sizing sleeve 202 is a circular straight pi...

Embodiment 2

[0046] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the cooling device 5 includes a water tank box 501, two U-shaped grooves 502 are symmetrically arranged at both ends of the water tank box 501, and two third legs are symmetrically arranged at the bottom of the water tank box 501 503, a number of limit grooves 507 are evenly distributed in front of the third leg 503, a support seat 504 is arranged below the third leg 503, and a locking nail 508 is installed in front of the support seat 504, and the third leg 503 goes up and down along the support seat 504 Slide to adjust the height of the water tank box 501, and the locking nail 508 is locked and inserted into the limit groove 507 in front of the third leg 503 to fix the height of the water tank box 501; It is threadedly connected with the support base 504 , the sliding connection ensures the flexible movement of the third leg 503 , and the threaded connection ensures the locking of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com