Sectional type traction device for flat knitting machine and traction unit control method

A technology of flat knitting machine and pulling device, which is applied in the direction of weft knitting, knitting, textile and paper making, and can solve the problems of high manufacturing cost, complex structure of transmission mechanism, poor applicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

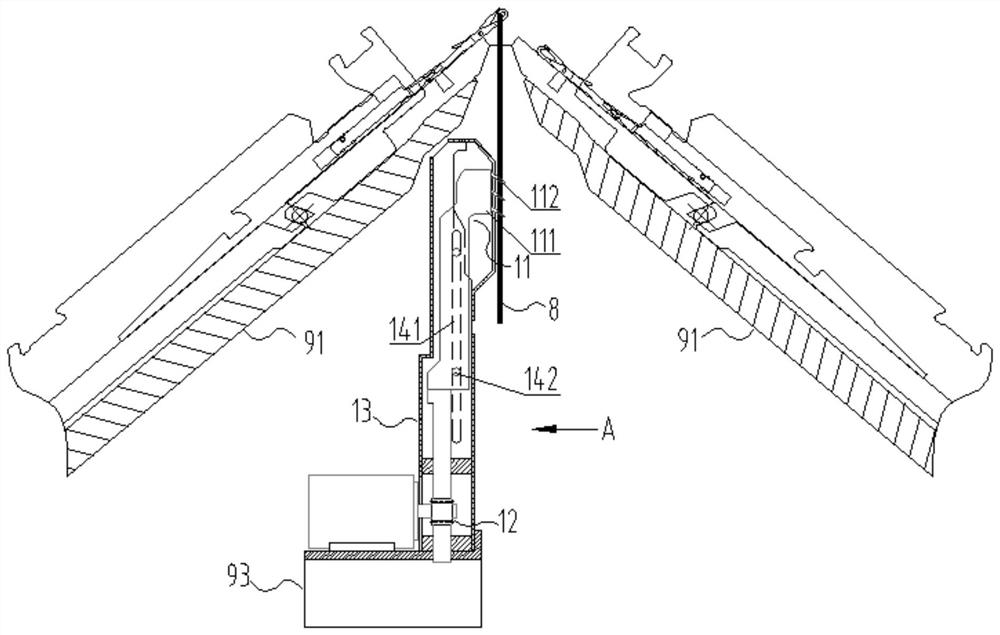

[0046] Such as Figure 1-3 The pulling device is arranged below the needle plate 91 of the flat knitting machine and on one side of the path of the braided fabric 8. The pulling device includes six horizontally arranged pulling mechanisms 1, and each pulling mechanism 1 is mainly composed of a fixed seat 13, a pulling mechanism The pull unit 11 and the drive unit 12 are composed. The pulling unit 11 is provided with a pulling hook 112 for hooking the braided fabric, the driving unit 12 is fixedly arranged on the fixed upper seat 13, and a driving end 1211 which can move up and down is provided on it, and the pulling unit 11 passes through a relatively movable The guide structure formed by the guide piece and the guide groove can be slidably arranged on the fixed seat 13, and the pulling unit 11 moves upward under the action of the contact driving of the driving end 1211 of the driving unit 12, and the pulling unit 11 moves upward when the driving end moves down. It will move ...

Embodiment 2

[0055] Several pulling mechanisms 1 that make up the pulling device of this embodiment are arranged on as figure 1 The braided fabric 8 under the needle plate 91 of the shown flat knitting machine is on one side or both sides of the path, and similarly, several pulling mechanisms 1 on the one side or both sides are fixed side by side on the corresponding side of the transverse base. Seat 93.

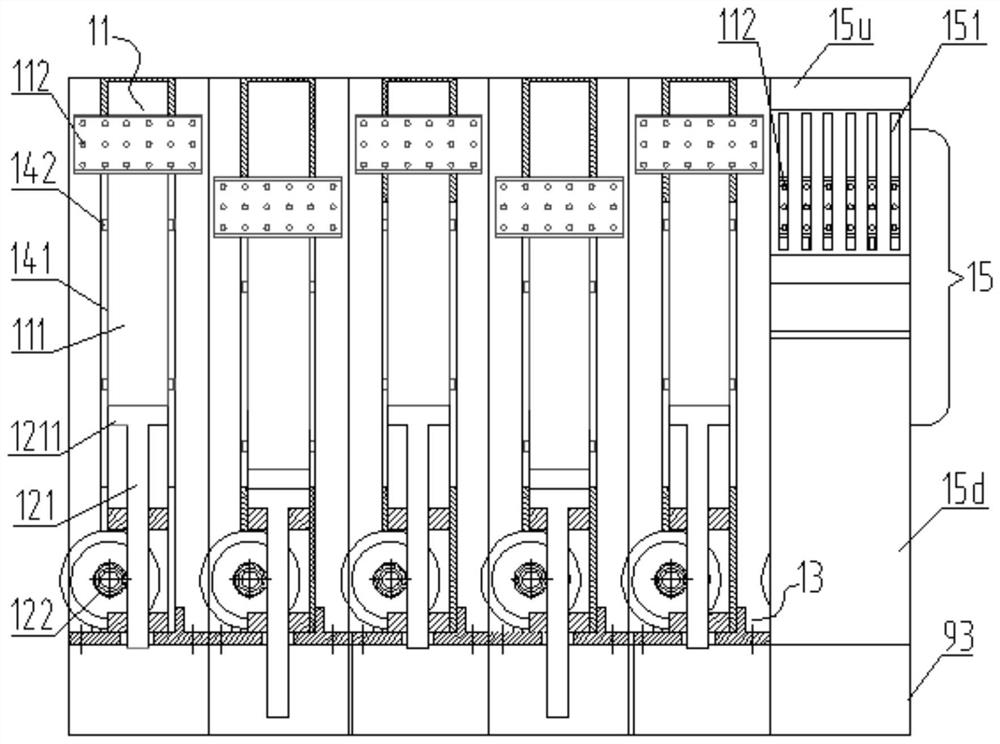

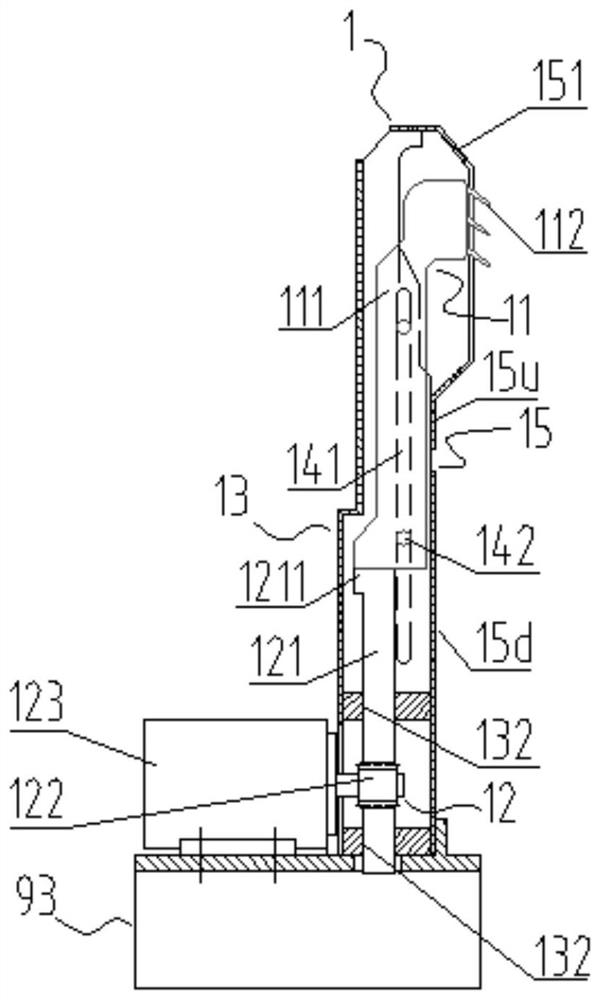

[0056] Such as Figure 4 , same as above-mentioned embodiment 1, its pulling mechanism 1 comprises fixed seat 13, pulling unit 11, drive unit 12 and shield plate 15, is provided with the shield plate 15 of slotted hole 151 and is arranged on fixed seat 13 corresponding to On one side of the braid, the pulling unit 11 is slidably arranged on the fixing seat 13 through a guide structure formed by a relatively movable guide piece and a guide groove. In this embodiment, guide grooves are provided on both sides (or one side) of the pulling unit 11. The guide grooves on each side are compose...

Embodiment 3

[0060] Figure 6 , a number of pulling mechanisms 1 that make up the pulling device of this embodiment are arranged as figure 1 The braided fabric 8 under the needle plate 91 of the shown flat knitting machine is on one side or both sides of the path, and similarly, several pulling mechanisms 1 on the one side or both sides are fixed side by side on the corresponding side of the transverse base. Seat 93.

[0061] Such as Figure 7 , 8 Similarly, the pulling mechanism 1 of this embodiment includes a fixing base 13 , a pulling unit 11 , a driving unit 12 , and a shield plate 15 disposed on one side of the fixing base and provided with a long slot 151 . The guide is arranged on the pulling unit 11, and a guide composed of two cylindrical pins 142 arranged up and down is provided on both sides (or one side) of the pulling unit; the guide groove 141 is a straight groove connected vertically and The straight inclined combination groove formed by the inclined groove at the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com