Double-layer buoyant raft vibration reduction device and method

The technology of a vibration damping device and a floating raft is applied in the field of vibration damping equipment and vibration isolation. The effect of suppressing low frequency vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

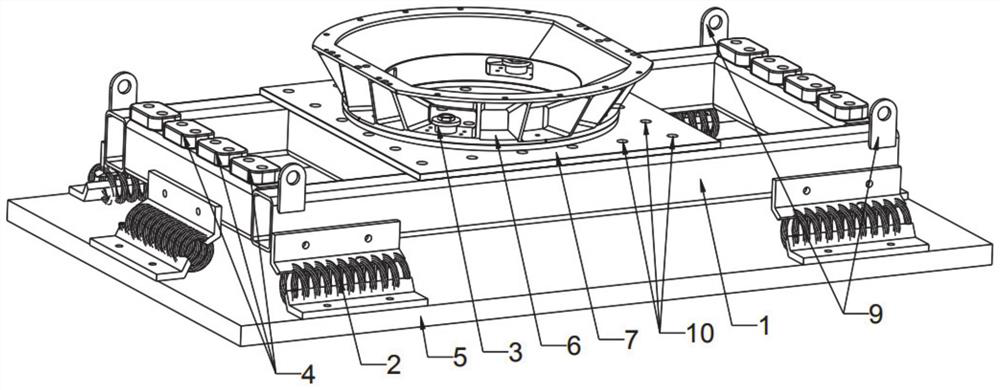

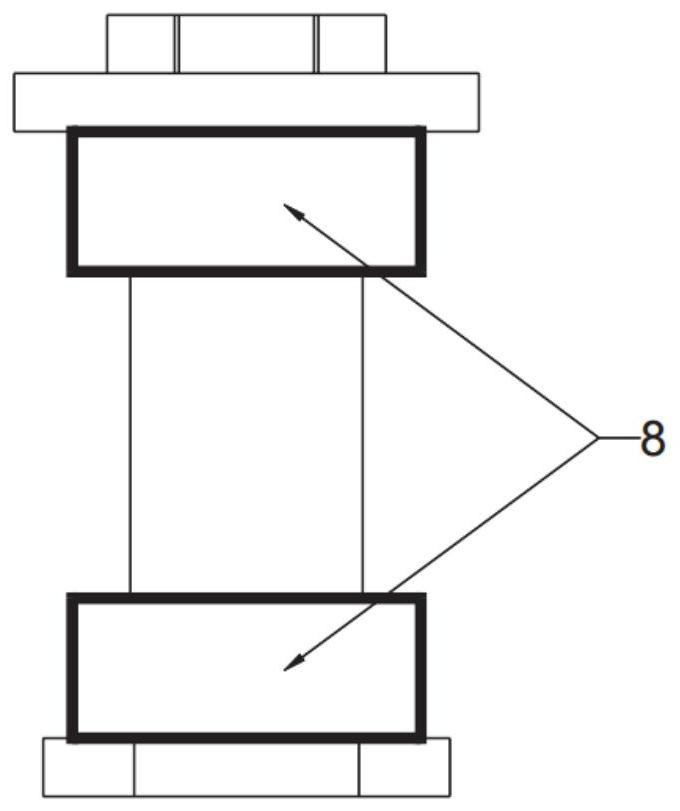

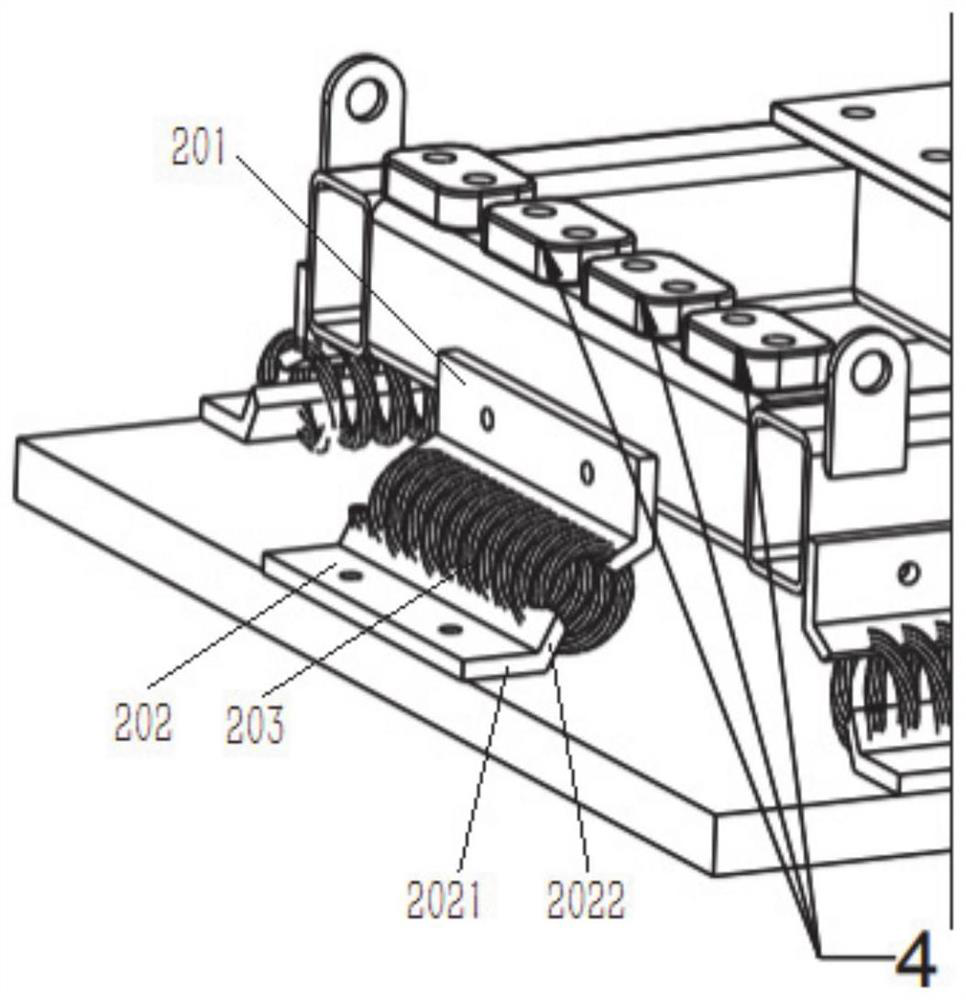

[0028] Such as Figure 1-Figure 3 As shown, this embodiment provides a double-layer floating raft vibration damping device, which includes a base 5, a raft frame 1 and a transfer tool 6 arranged sequentially from bottom to top, and the base 5 and raft frame 1 are damped by two sets of steel wire ropes. 2, the helical centerlines of the steel wire ropes 203 in the two groups of steel wire rope dampers 2 are arranged vertically and horizontally to each other, and the steel wire rope dampers 2 are installed obliquely to absorb vibration in any direction between the base 5 and the raft frame 1; The raft frame 1 and the transfer tooling 6 are connected by a vibration-absorbing connector 3 with a vertical axis. The two ends of the vibration-damping connector 3 are provided with metal rubber gaskets 8, which can absorb the raft frame 1 and the transfer tooling. 6 between vertical vibrations.

[0029] It can be understood that the wire rope damper here forms a first-stage shock absor...

Embodiment 2

[0048] This embodiment provides a double-layer floating raft vibration reduction method, which utilizes the double-layer floating raft vibration reduction device described in Embodiment 1, including the following steps:

[0049] The base 5 is arranged at the bottom surface of the support, and the base 5 receives the vibration from the bottom surface of the support;

[0050] When the vibration of the base 5 is transmitted to the raft 1, the vibration in any direction can be decomposed into component forces along the horizontal and vertical directions in the space, and weakened by the wire rope shock absorber 2;

[0051] The vibration weakened by the wire rope damper 2 is transmitted to the raft frame 1, and the vibration of the raft frame 1 is vertically attenuated by the vibration-damping connector 3 and then transmitted to the transfer tool 6, which is used to install the equipment to be damped .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com