Drawer type intelligent optical fiber distribution frame

A technology of intelligent optical fiber and distribution frame, applied in the direction of fiber mechanical structure, etc., can solve problems such as insufficient optical cable redundancy, optical fiber distribution box cannot be pulled out smoothly, affecting the operation accuracy of operation and maintenance personnel, etc., so as to reduce work pressure. , Improve the efficiency of operation and maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

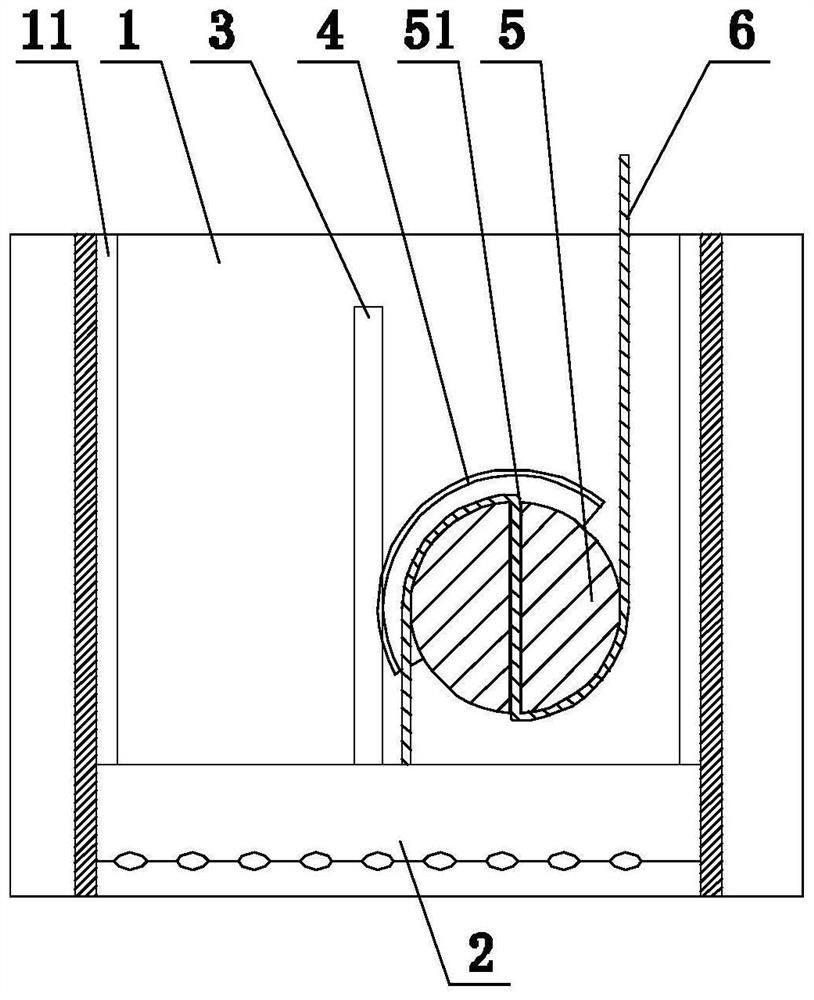

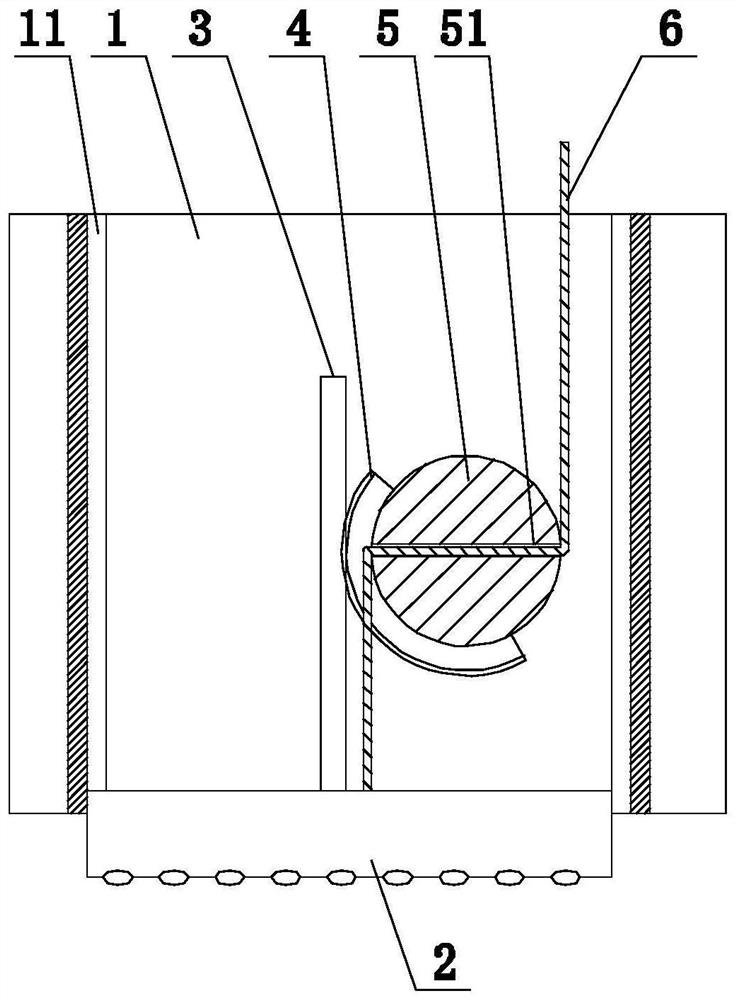

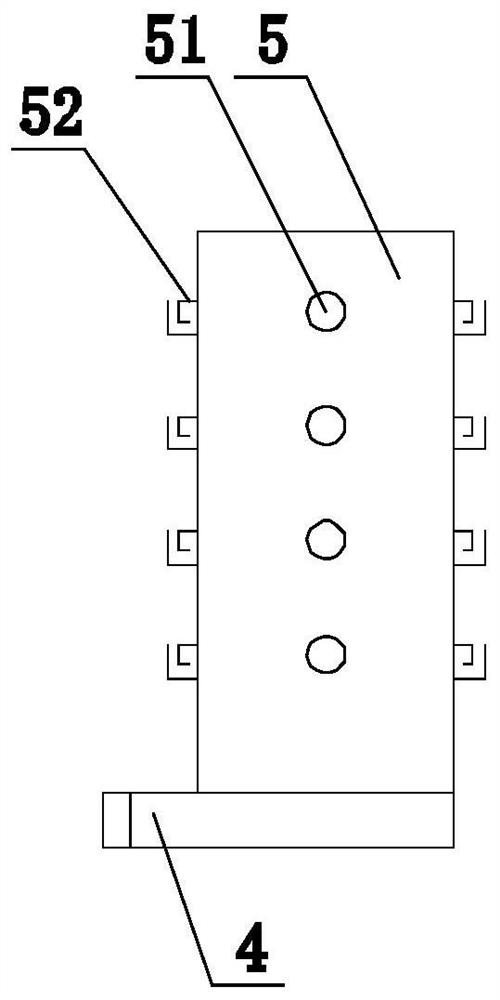

[0018] like Figure 1-3 shown, figure 1 It is a schematic structural diagram of a drawer-type intelligent optical fiber distribution frame where the distribution box is retracted into the casing. figure 2 It is a schematic structural diagram of a drawer-type intelligent optical fiber distribution frame drawn out of the casing of the distribution box proposed by the present invention. image 3 It is a structural schematic diagram of a winding column of a drawer-type intelligent optical fiber distribution frame proposed by the present invention.

[0019] refer to Figure 1-3 , a drawer type intelligent optical fiber distribution frame proposed by the present invention includes a housing 1, at least one wiring box 2 and a pay-off mechanism for adjusting the length of the optical fiber 6. The wiring box 2 can be horizontally slidably installed on the housing 1;

[0020] The pay-off mechanism includes a gear 4, a rack 3 and a winding column 5;

[0021] The rack 3 is horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com