Intelligent concrete pouring device

A concrete and intelligent technology, applied in the field of concrete pouring, can solve problems such as inconvenient operation, high cost of use, and reduced pouring efficiency, and achieve the effects of improving pouring efficiency, good fluidity, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

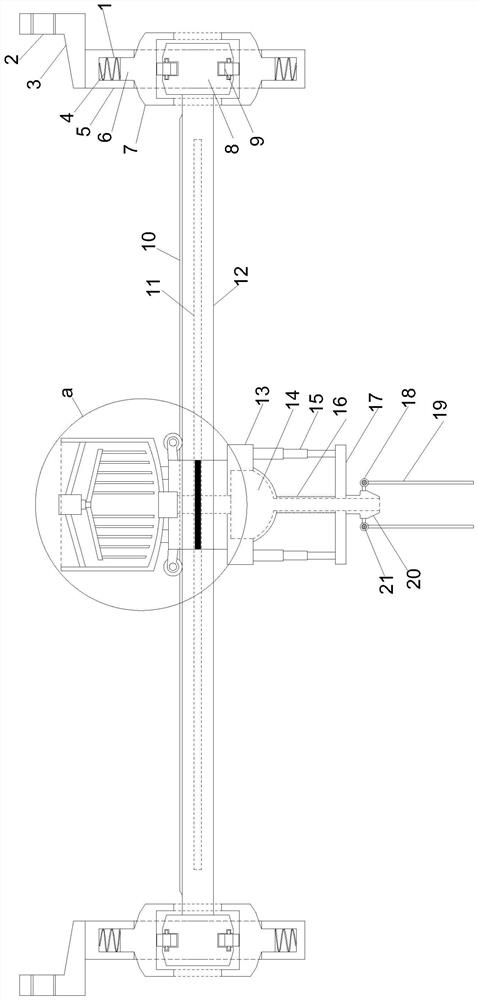

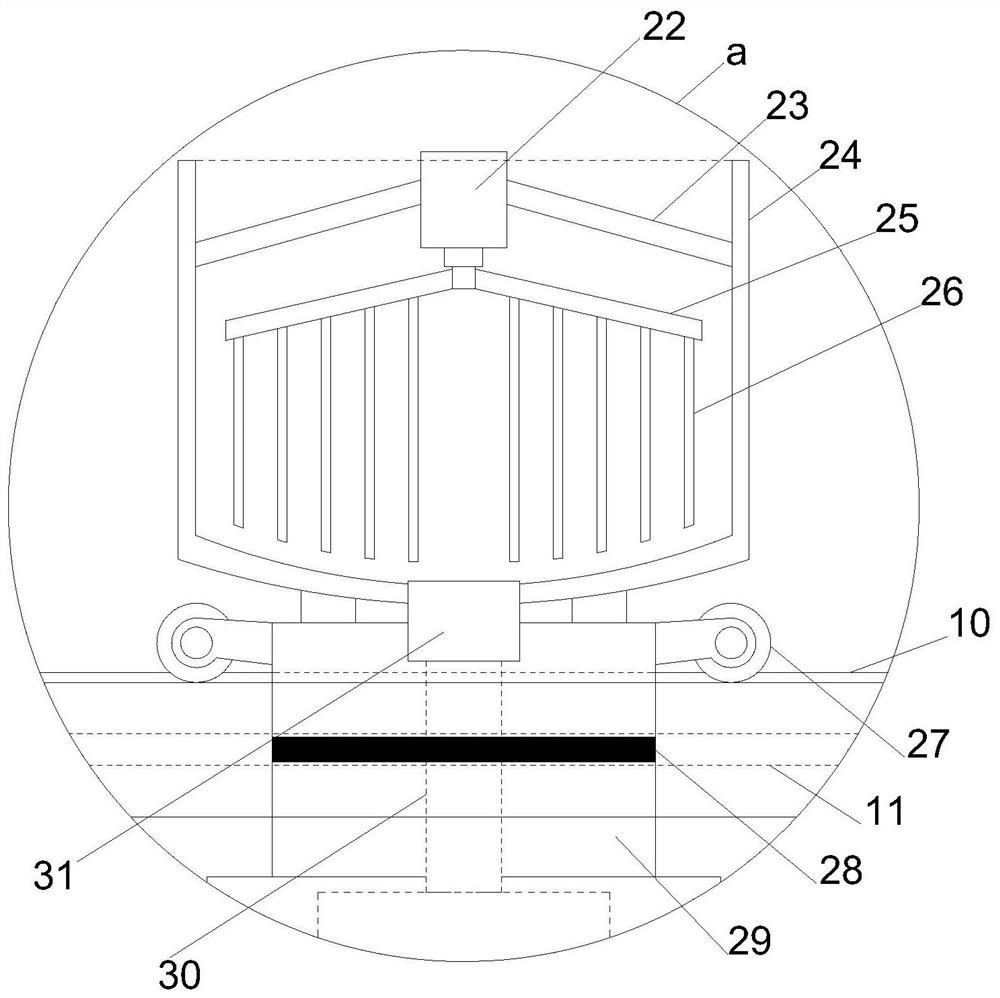

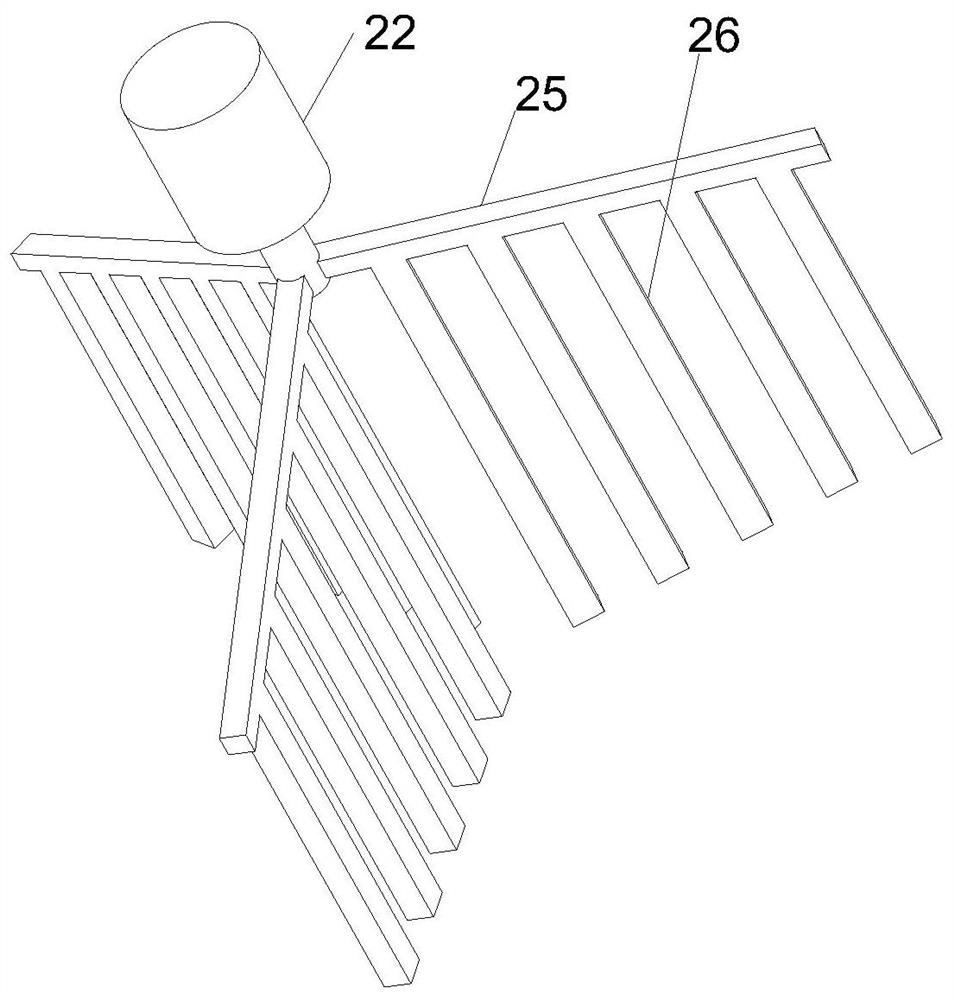

[0021] see Figure 1~3 , in an embodiment of the present invention, an intelligent pouring device for concrete includes support mounting frames 5 arranged symmetrically on both sides, the support mounting frames 5 are horizontally and longitudinally arranged, and the upper ends of the support mounting frames 5 are vertically provided with fixed mounting frames 3 , the fixed mounting frame 3 is provided with a fixed mounting hole 2, the inside of the supporting mounting frame 5 is horizontally and vertically provided with a guide mounting frame 7, and the upper and lower ends of the guide mounting frame 7 are vertically provided with a guide mounting column 6 in the middle position. The inner side of the support installation frame 5 cooperates with the guide installation column 6 to be provided with a guide installation groove 1, and the guide installation column 6 is connected to the bottom of the guide installation groove 1 through the return spring 4, and the inside of the gu...

Embodiment 2

[0024] On the basis of Embodiment 1, the rotating mounting column 25 is driven to rotate by the drive motor 22, and the rotating stirring column 26 rotates thereupon to realize the mixing of the concrete and ensure the fluidity of concrete pouring. Through the return spring 4, the device can be Overcome small-scale ups and downs and vibrations, and improve the operating stability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com