Commercial concrete transportation monitoring and early warning method

A technology for commercial concrete and early warning systems, applied in chemical instruments and methods, alarms, measuring devices, etc., can solve problems such as concrete supervision loopholes, non-compliance, and reduced concrete quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

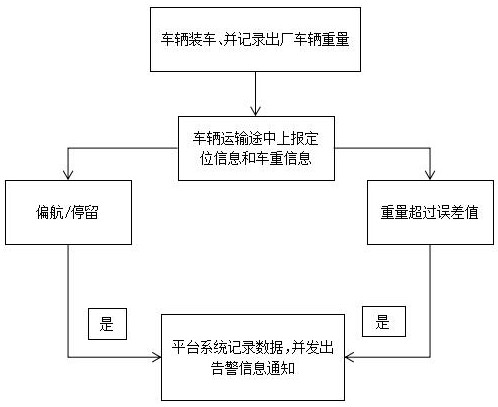

[0049] Embodiment 1: The present invention proposes a method for commercial concrete transportation monitoring and early warning, including the following steps:

[0050] S1; Install mixing tank weighing equipment, positioning system, navigation and early warning device, and concrete density sensor on the concrete mixer truck;

[0051] A mixing tank weighing device is installed on the concrete mixer truck frame, and the mixing tank weighing device includes a pressure data acquisition device and a pressure data sending device; the pressure data acquisition device is a pressure sensor;

[0052] Each pressure data acquisition device has a unique ID code; each positioning system includes a unique ID code;

[0053] A positioning system is installed on the body of the concrete mixer truck, and the positioning system is a GPS satellite positioning system or a Beidou navigation system;

[0054] The positioning system collects the longitude and latitude data of the transport vehicle, t...

Embodiment 2

[0091] Embodiment 2: The present invention also proposes a commercial concrete transportation monitoring and early warning system. The commercial concrete transportation monitoring and early warning system adopts a commercial concrete transportation monitoring and early warning method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com