Unequal-thickness glass and processing technology thereof

A processing technology, thick glass technology, applied in stone processing tools, stone processing equipment, metal processing equipment, etc., can solve the problems that flat glass cannot be effectively folded, ultra-thin glass is difficult to mass-produce, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A kind of unequal thickness glass, which is essentially flat glass with a strip-shaped groove on one side, and the distance from the bottom of the groove to the side away from the groove is less than 0.1mm, and its processing technology includes the following steps:

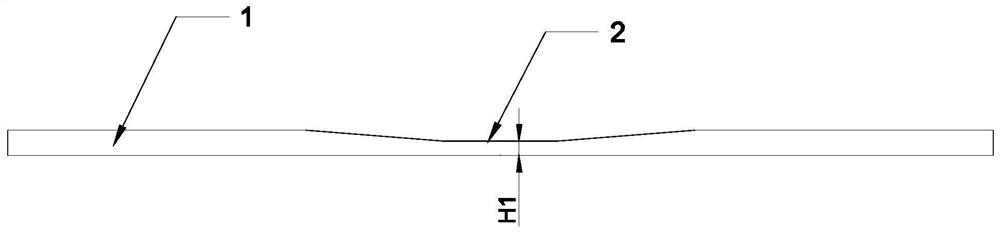

[0035] (1), select a plate glass 1 with a thickness of 0.55mm, and process the plate glass 1 with a CNC engraving machine, process a strip-shaped depression 2 on one side of the plate glass 1, and the thickness H1 of the strip-shaped depression 2 is 0.2mm , the control thickness deviation is ±0.01mm;

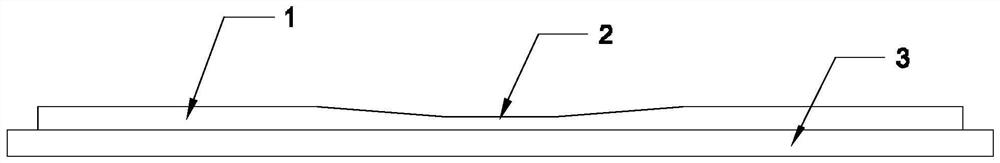

[0036] (2), the one side that does not have depression 2 on the flat glass 1 in step (1) gained product is coated with UV viscose, then fit and be fixed on the protective substrate 3, the size of the protective substrate 3 is 5mm larger than the flat glass 1, then Use a brush to sweep in 2.5D, and then use a wool blanket to sweep in 2.5D to complete the polishing;

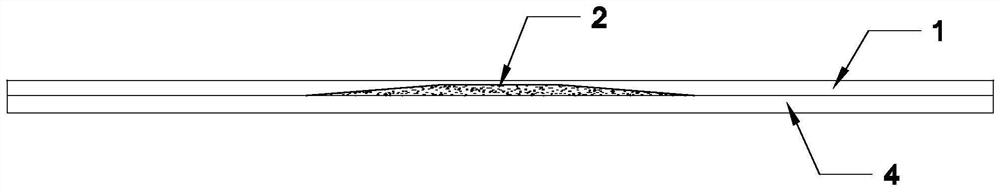

[0037] (3), degumming and separating the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com