A diaphragm material for a power lithium battery

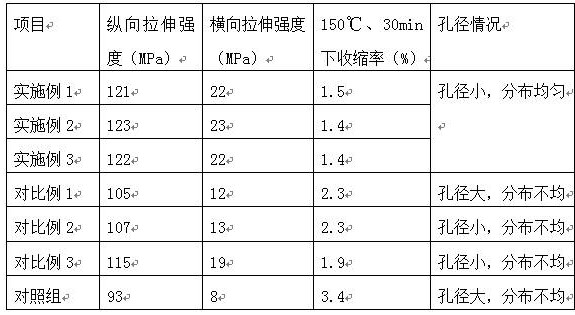

A separator material, lithium battery technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problems of low porosity, uneven pore size distribution, and general mechanical properties of battery separators, and achieve good heat shrinkage, Effects of high porosity, good mechanical properties and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A diaphragm material for a power lithium battery, the preparation method of the diaphragm material comprises the following process steps:

[0015] S1: Clean the corn cobs, dry them in an oven until the water content is between 6-9%, crush them, pass through a 45-mesh sieve, and soak them in a sodium hydroxide solution with a mass concentration of 4.0% for 70 minutes. The soaking temperature is 30°C, filter after soaking, dry in an oven at 70°C for 3 hours, send it into a muffle furnace, heat up to 550°C, keep warm for 2 hours, continue to heat up to 620°C, keep warm for 10 minutes, Cool naturally to room temperature, and further grind until the particle size is between 0.4-0.8 microns;

[0016] S2: Weigh 12.5 grams of butyl titanate and place it in a beaker, stir at a speed of 200 rpm, add 33 ml of absolute ethanol to the beaker, continue stirring for 20 minutes, and then add 18 ml of acetic acid-ethanol to the beaker Mix the solution, continue to stir for 40 minutes, ...

Embodiment 2

[0020] A diaphragm material for a power lithium battery, the preparation method of the diaphragm material comprises the following process steps:

[0021] S1: Clean the corn cobs, dry them in an oven until the water content is between 6-9%, crush them, pass through a 52-mesh sieve, and soak them in a sodium hydroxide solution with a mass concentration of 4.3% for 75 minutes. The soaking temperature is 31°C, filter after soaking, dry in an oven at 75°C for 4 hours, send it into a muffle furnace, heat up to 560°C, keep warm for 2.5 hours, continue to heat up to 625°C, keep warm for 12 minutes, Cool naturally to room temperature, and further grind until the particle size is between 0.4-0.8 microns;

[0022] S2: Weigh 12.8 grams of butyl titanate and place it in a beaker, stir at a speed of 210 rpm, add 34 ml of absolute ethanol to the beaker, continue stirring for 25 minutes, and then add 20 ml of acetic acid-ethanol to the beaker Mix the solution, continue to stir for 45 minutes...

Embodiment 3

[0026] A diaphragm material for a power lithium battery, the preparation method of the diaphragm material comprises the following process steps:

[0027] S1: Clean the corn cobs, dry them in an oven until the water content is between 6-9%, crush them, pass through a 60-mesh sieve, and soak them in a sodium hydroxide solution with a mass concentration of 4.5% for 80 minutes. The soaking temperature is 32°C, filter after soaking, dry in an oven at 80°C for 5 hours, send it into a muffle furnace, heat up to 570°C, keep warm for 3 hours, continue to heat up to 630°C, keep warm for 15 minutes, Cool naturally to room temperature, and further grind until the particle size is between 0.4-0.8 microns;

[0028] S2: Weigh 13.0 g of butyl titanate and place it in a beaker, stir at a speed of 220 rpm, add 36 ml of absolute ethanol to the beaker, continue stirring for 30 minutes, and then add 22 ml of acetic acid-ethanol to the beaker Mix the solution, continue to stir for 50 minutes, heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com