A kind of flour product automatic noodle mixer and pastry processing technology

A technology for dough mixers and dough products, which is used in dough extruders, dough mixers, cleaning hollow objects, etc., can solve the problems of insufficient machine cleaning and dough sticking to the wall, etc., so as to improve flexibility and taste, and increase efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

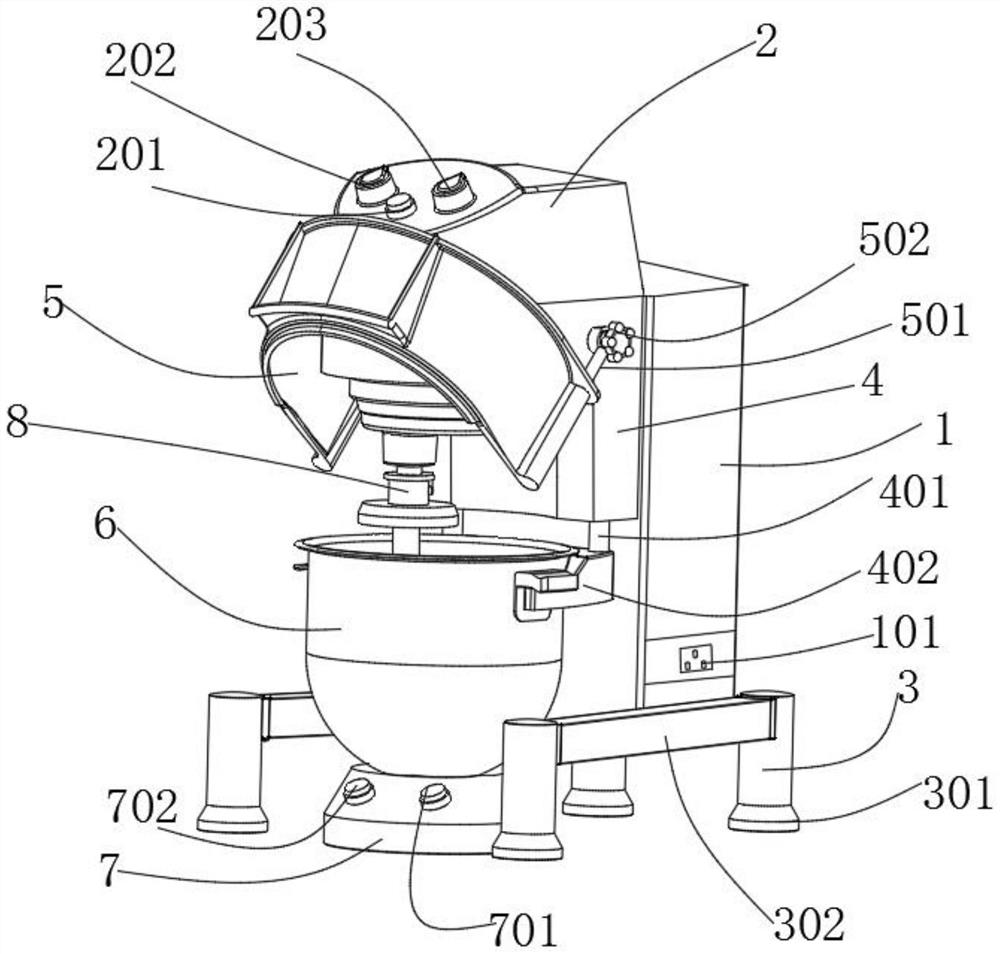

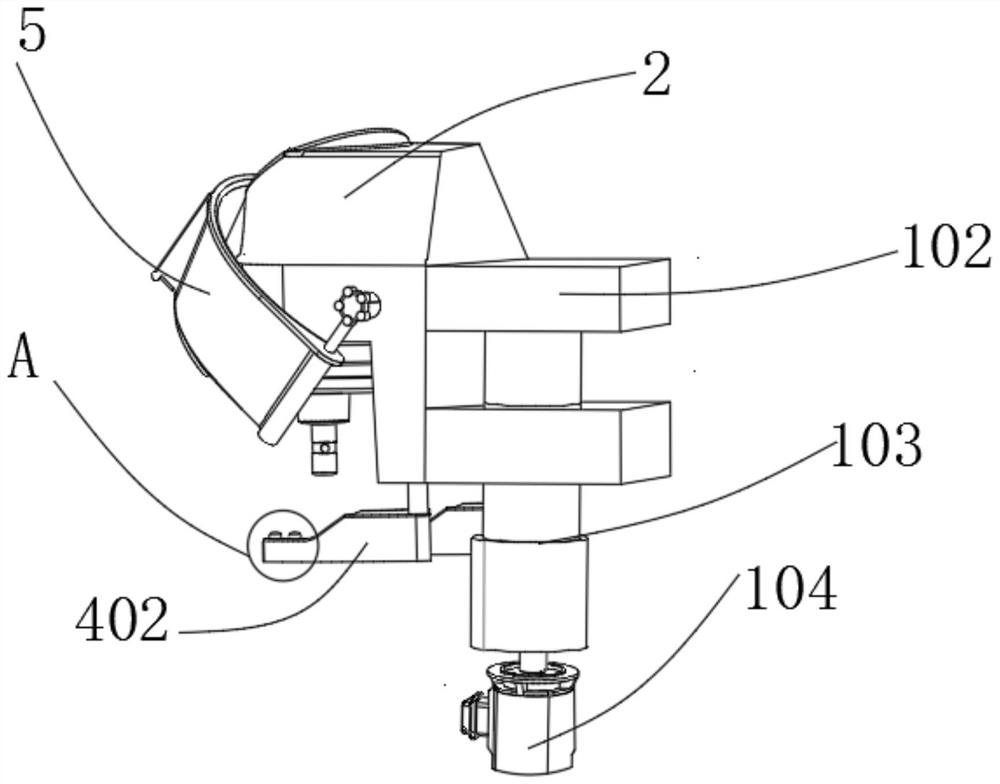

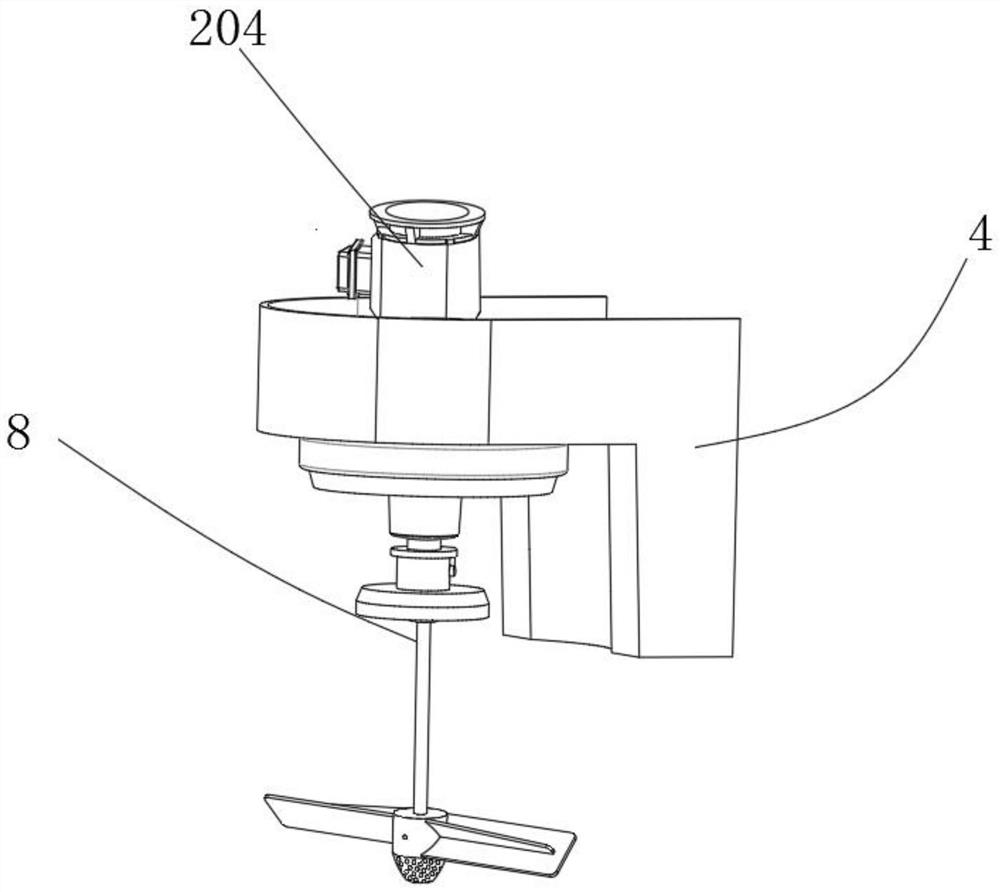

[0038] like Figure 1-7 As shown, an automatic noodle kneading machine for flour products comprises a back box 1, an upper cover 2, a support frame 3 and a mixing bucket 6, the lower side of the back box 1 is provided with a jack 101, and the inside of the back box 1 is provided with a No. motor 104, the upper end of No. 1 motor 104 is fixedly connected to the lifting rod 103, the other end of the lifting rod 103 is fixedly connected to the connection block 102, the other end of the connection block 102 is fixedly connected to the lifting box 4, and the lifting box 4 is movably connected to the fixed support rod 401, The fixed support rod 401 is fixedly connected to the rear box body 1, and the No. 1 motor drives the lifting rod 103 to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com