Frequency control method and device for semi-autogenous mill and electronic equipment

A semi-autogenous mill and frequency control technology, applied in the field of ore grinding, can solve the problems of semi-autogenous mill efficiency and product quality decline, waste of human resources, etc., to achieve the effect of improving efficiency and product quality, and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

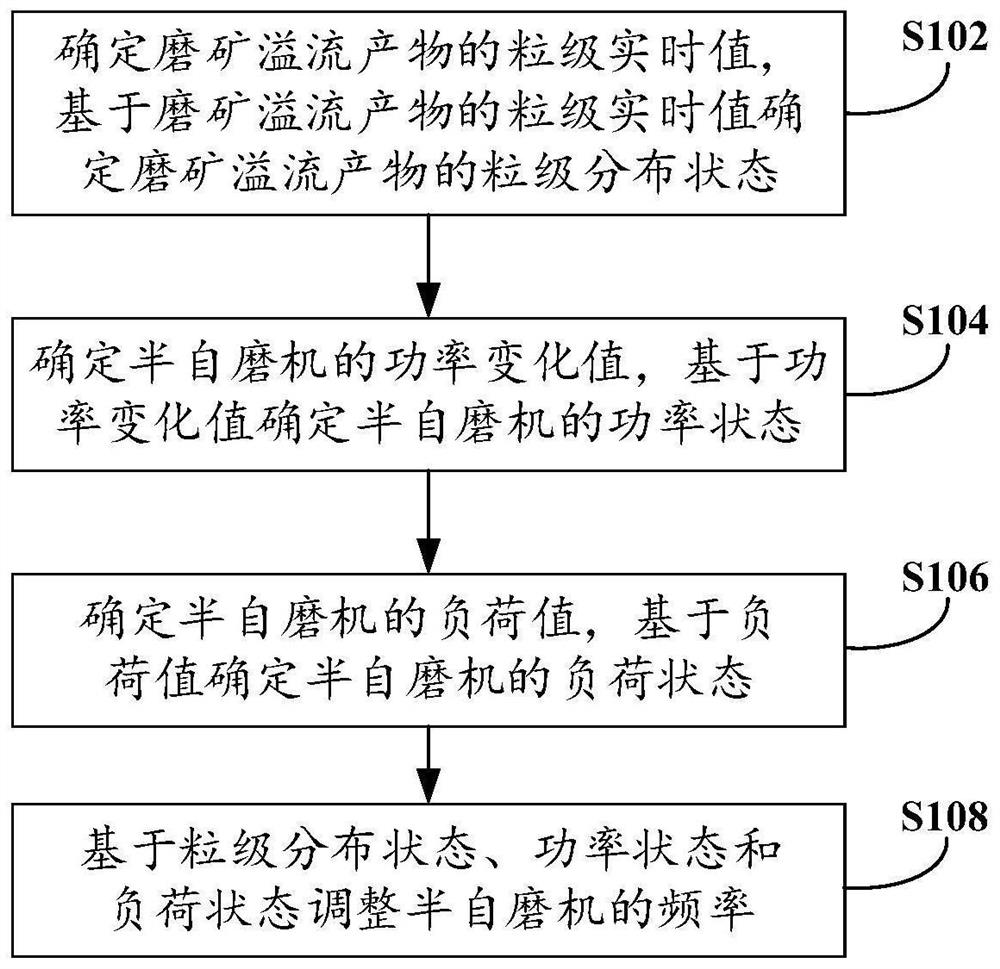

[0030] see figure 1 A flow chart of a semi-autogenous mill frequency control method shown, the semi-autogenous mill frequency control method includes the following steps:

[0031] Step S102, determining the real-time particle size value of the grinding overflow product, and determining the particle size distribution state of the grinding overflow product based on the real-time particle size value of the grinding overflow product.

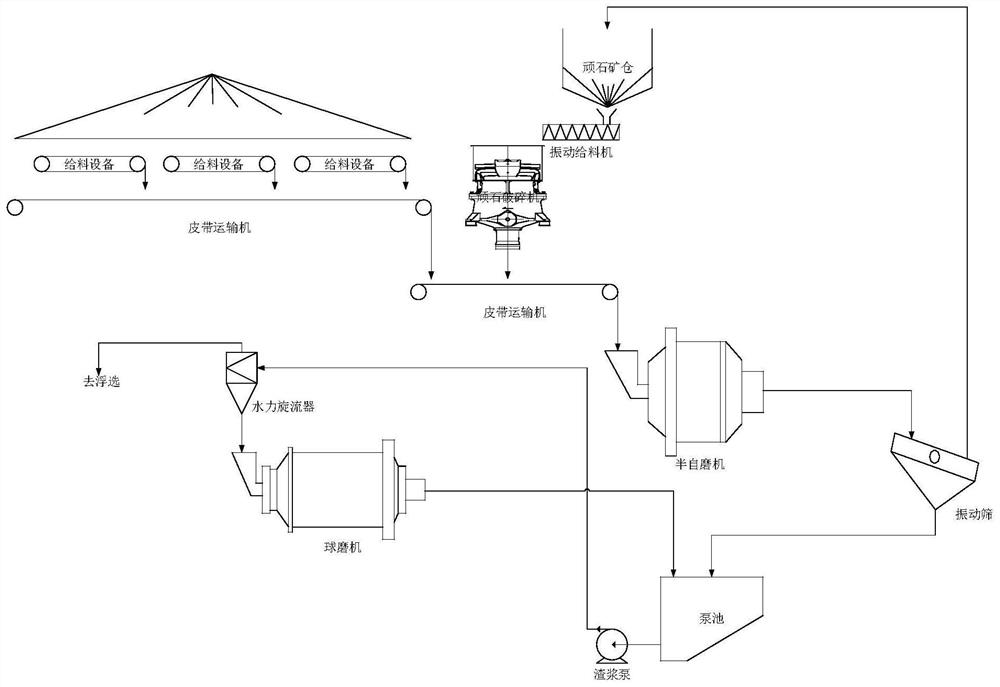

[0032] The above-mentioned semi-autogenous mill frequency control method is applied to the controller of the semi-autogenous mill. The autogenous mill in this embodiment can belong to the SAB semi-autogenous mill grinding process system, wherein the SAB semi-autogenous mill grinding process system includes a semi-autogenous mill. Self-grinding machines, vibrating screens and pump pools.

[0033] The drive of the autogenous mill is generally driven by an asynchronous motor or a synchronous motor, and it adopts unilateral transmission, double-sided t...

Embodiment 2

[0046] The embodiment of the present invention also provides another semi-autogenous mill frequency control method; this method is implemented on the basis of the method in the above embodiment; this method focuses on the specific implementation of determining the particle size distribution of the grinding overflow product.

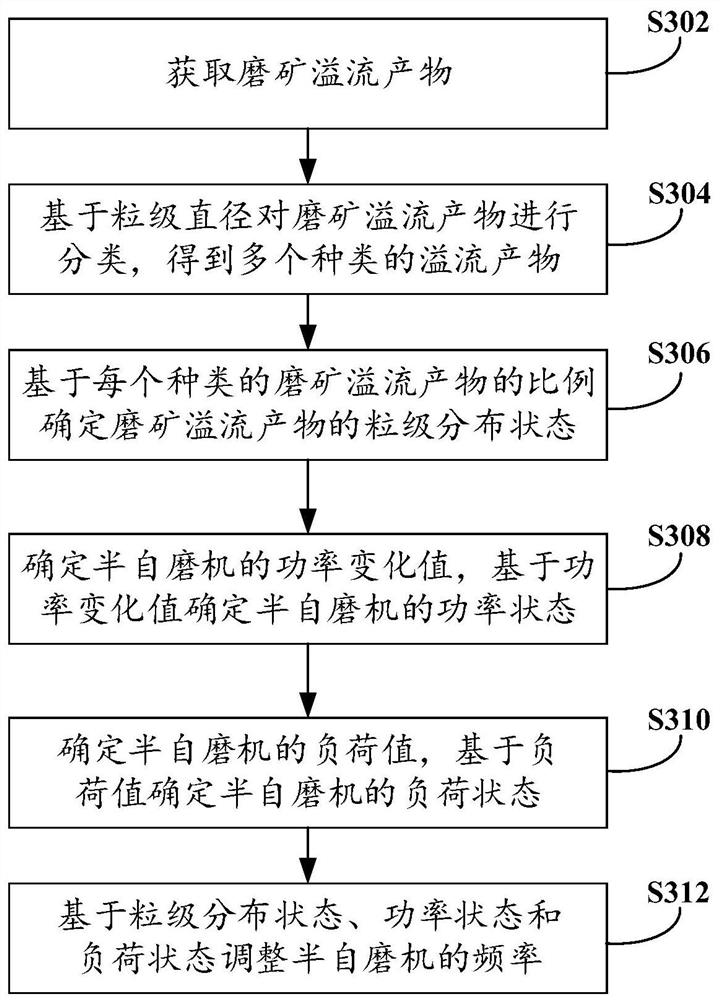

[0047] Such as image 3 The flow chart of another semi-autogenous mill frequency control method shown, the semi-autogenous mill frequency control method includes the following steps:

[0048] Step S302, obtaining the grinding overflow product.

[0049] In this embodiment, the grinding overflow product can be detected in real time, which can also be called the grinding overflow product.

[0050] Step S304, classify the overflow products of the grinding based on the particle size diameter to obtain multiple types of overflow products.

[0051] The particle size diameter of the overflow product is not the same, and the overflow product can be classified ac...

Embodiment 3

[0094] Corresponding to the above method embodiment, the embodiment of the present invention provides a semi-autogenous mill frequency control device, such as Figure 4 A structural schematic diagram of a semi-autogenous mill frequency control device shown, the semi-autogenous mill frequency control device includes:

[0095] The particle size distribution state determination module 41 is used to determine the particle size real-time value of the grinding overflow product, and determine the particle size distribution state of the grinding overflow product based on the particle size real-time value of the grinding overflow product;

[0096] A power state determination module 42, configured to determine the power change value of the semi-autogenous mill, and determine the power state of the semi-autogenous mill based on the power change value;

[0097] The load state determining module 43 is used to determine the load value of the semi-autogenous mill, and determines the load sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com