Pipeline inner wall ultrasonic cleaning system capable of automatically tracking frequency

An ultrasonic cleaning and automatic tracking technology, which is applied in the direction of vibration cleaning, general control system, fluid using vibration, etc., can solve the problems that the sediment cannot be effectively removed and the output power of the transducer is large, so as to enhance the cleaning ability and improve The effect of dredging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

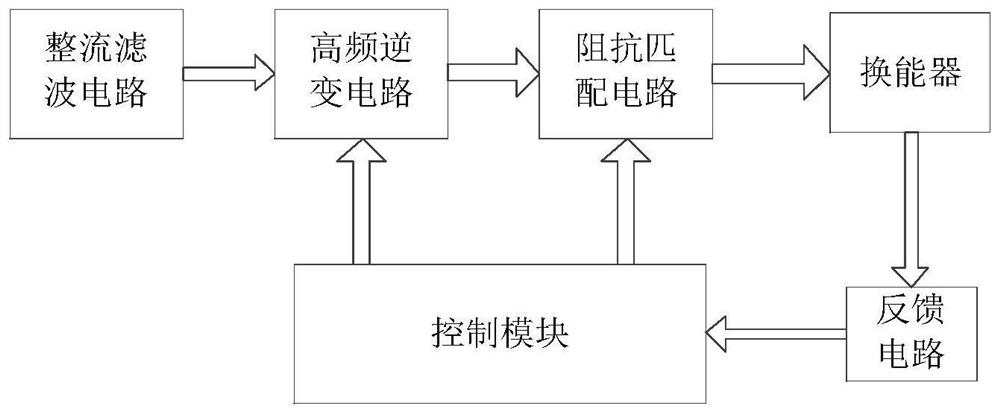

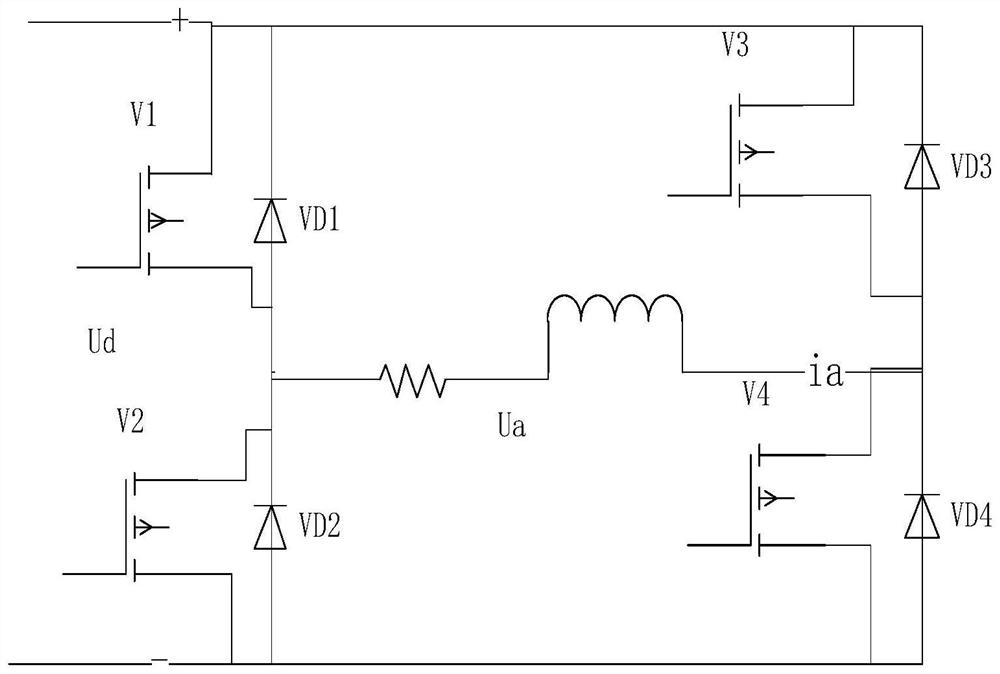

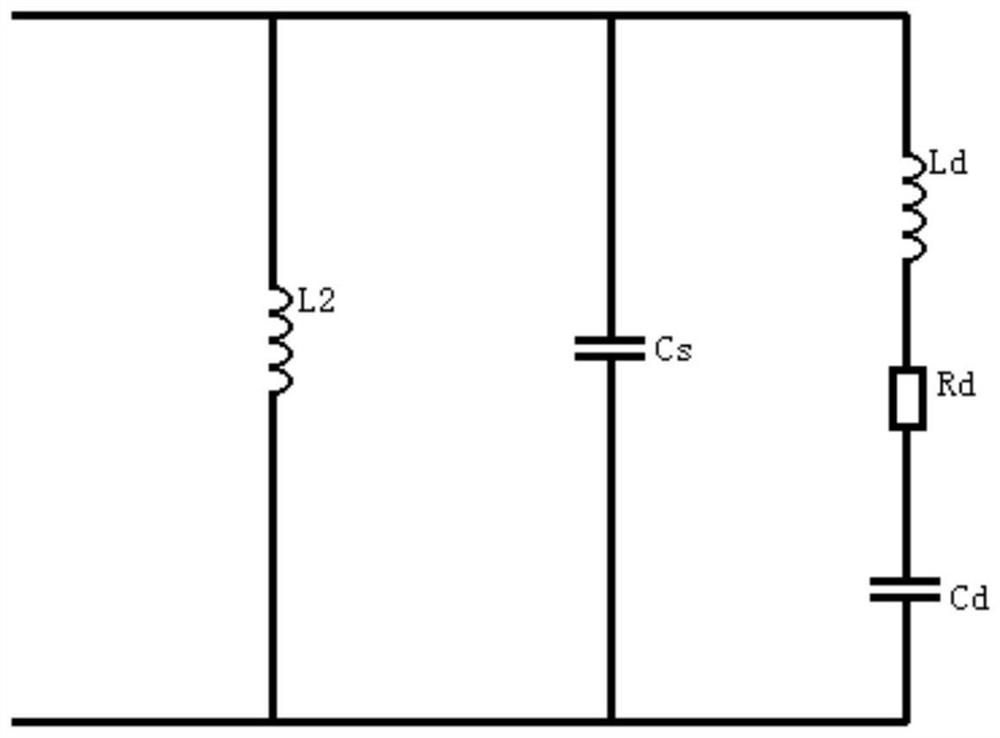

[0033] This embodiment provides an ultrasonic cleaning system for the inner wall of a pipeline that can automatically track the frequency, including a rectification filter circuit, a high-frequency inverter circuit, an impedance matching circuit, and a transducer connected in sequence; the connection control of the high-frequency inverter circuit and the impedance matching circuit Module, the control module is used to control the high-frequency inverter circuit and impedance matching circuit; the high-frequency inverter circuit is used to convert the input DC voltage that meets the requirements of the voltage amplitude into a medium-frequency high-power ultrasonic signal; the impedance matching circuit is used to adjust The load power is impedance matched with the transducer; the transducer is used for electro-acoustic conversion, and the transducer is connected to the feedback circuit. The feedback circuit includes a frequency tracking module, which is used to detect the freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com