Continuous variable stiffness spine joint based on pneumatics

A spine and stiffness technology, applied in the field of continuously variable stiffness spine joints, can solve problems such as poor bearing capacity and low stiffness of spine joints, and achieve the effects of high stiffness and bearing capacity, and strong external force resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

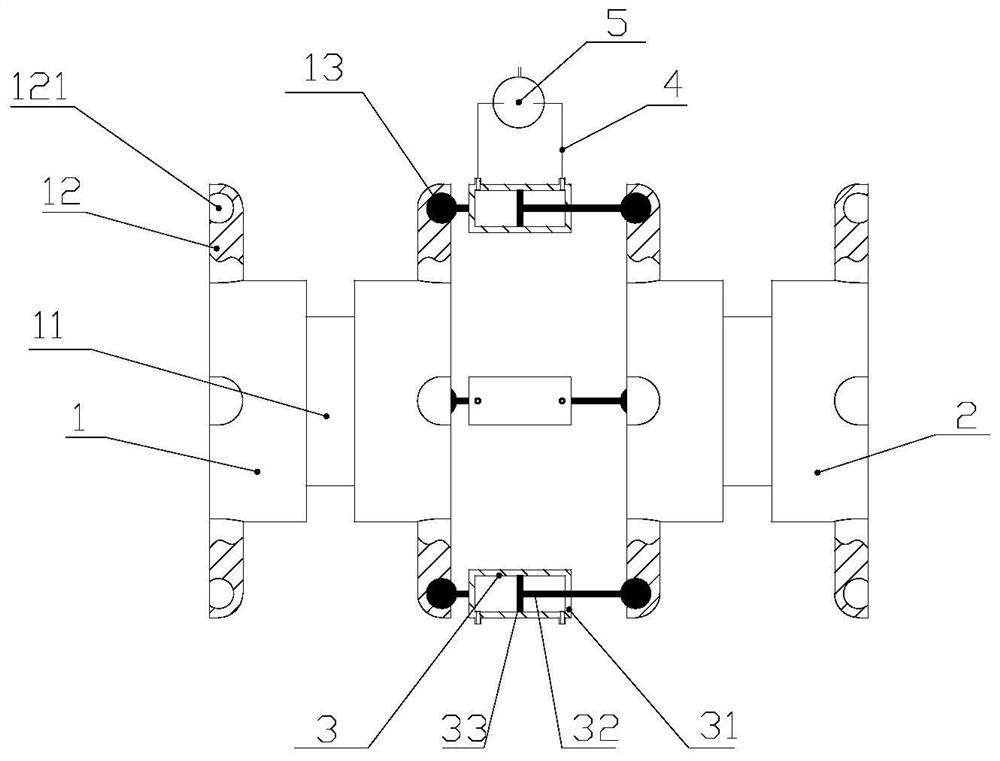

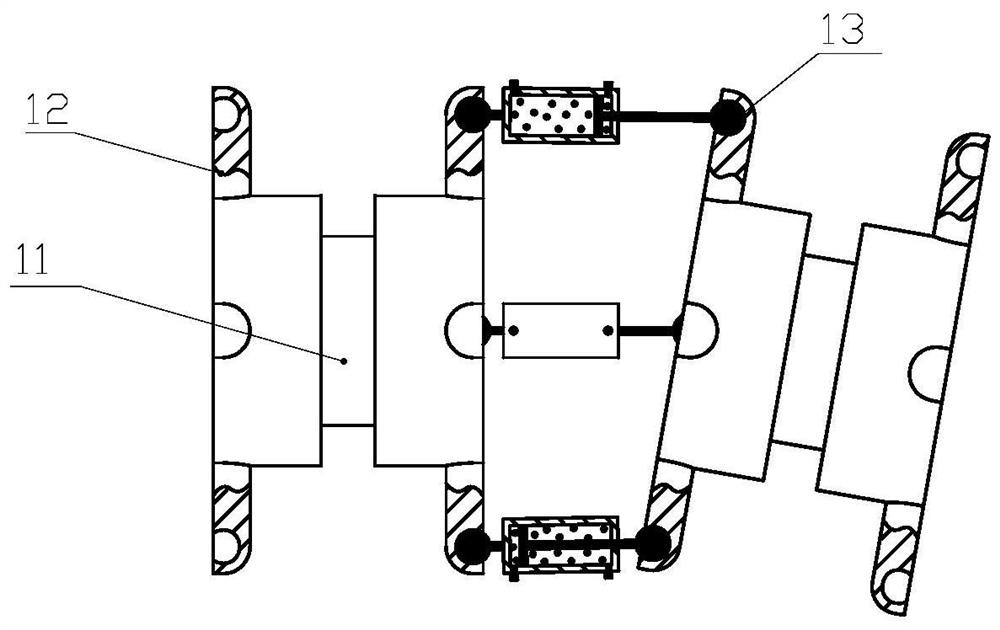

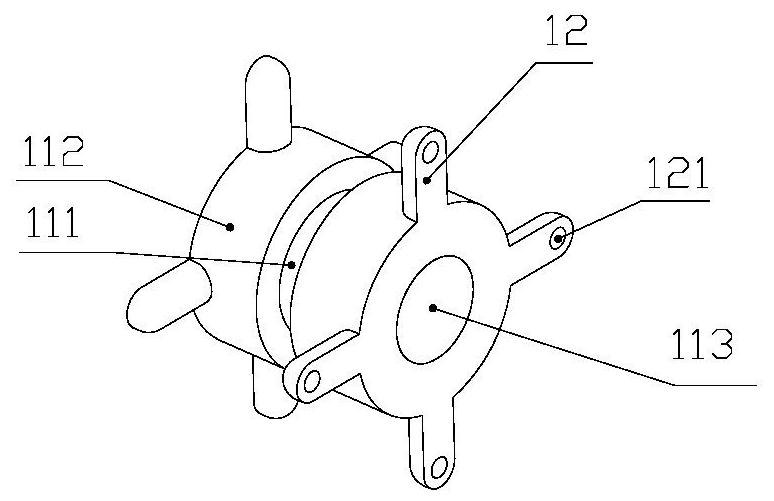

[0022] Specific implementation mode one: combine Figure 1~3 Describe this embodiment, a continuously variable stiffness spinal joint based on pneumatics, which includes a first spine 1 and a second spine 2 with the same structure, wherein the first spine 1 and the second spine 2 are connected end-to-end by several air cylinders 3 , several cylinders 3 are arranged parallel to each other, and one end of the cylinder body 31 of each cylinder 3 is hinged with the end of the first spine 1, and one end of the piston rod 32 of each cylinder 3 is hinged with the end of the second spine 2 , the chambers located on both sides of the piston 33 in the cylinder 3 are respectively connected with the external air source 5 through the air pipe 4 .

[0023] The first spine 1 and the second spine 2 constitute the main part of the joint, the external air source 5 and the air pipe 4 constitute the power transmission part of the joint, and the cylinder 31, piston 33 and piston rod 32 in the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com