Buoy suitable for floating platform

A floating, platform technology, used in floating buildings, special-purpose ships, ships, etc., can solve the problems of high cost, difficult manufacturing, installation and transportation, and large size of floating infrastructure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

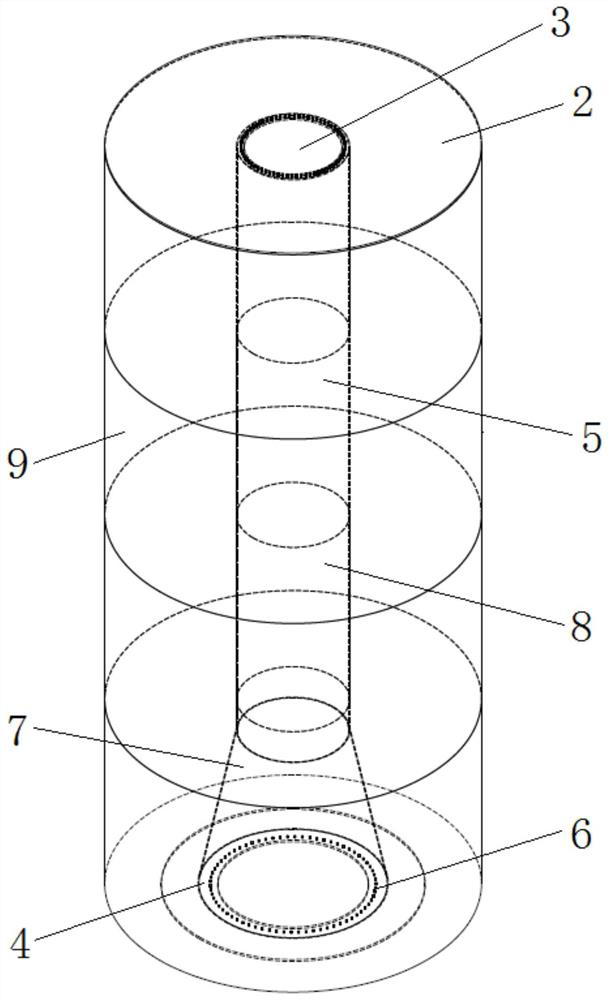

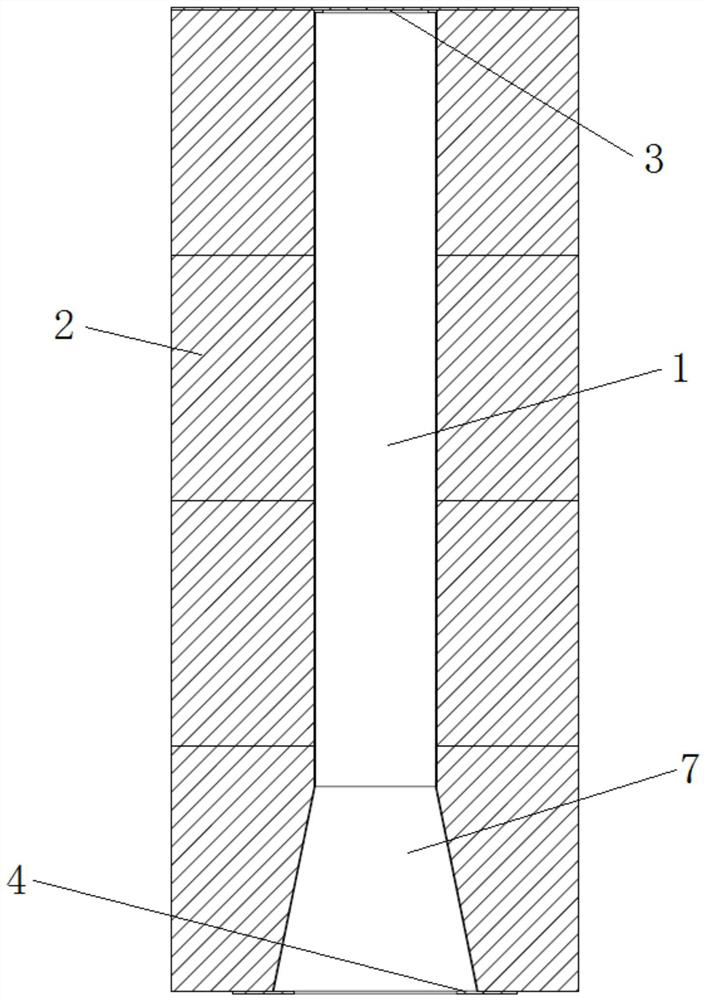

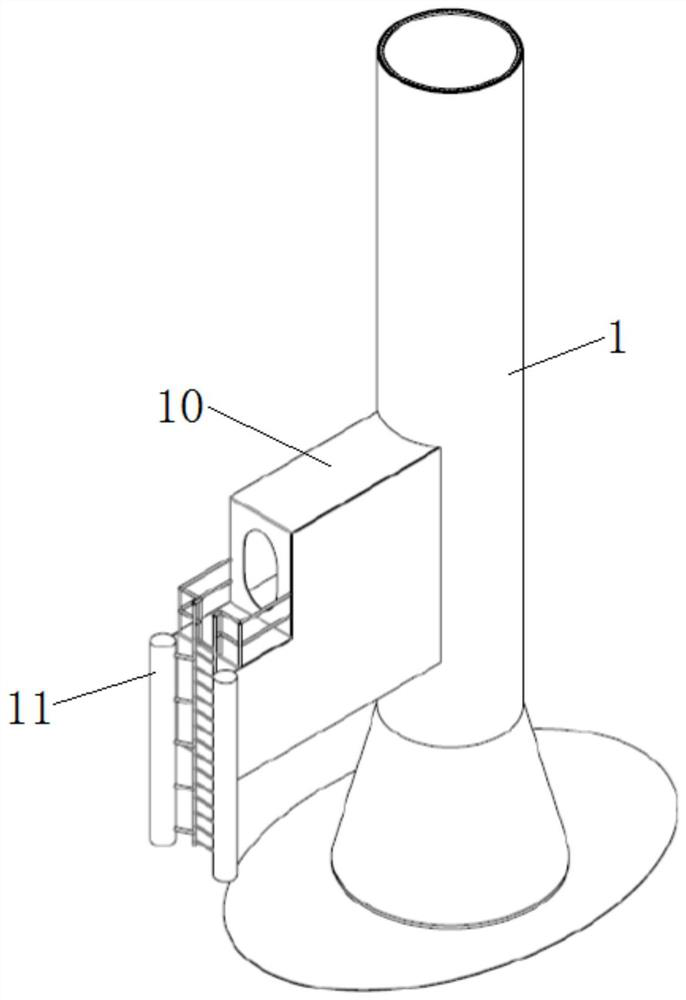

[0023] Such as figure 1 , figure 2 The shown buoy suitable for floating platforms includes a central steel structure 1 and a light material layer 2 clad on the outside of the central steel structure 1; the central steel structure 1 includes a top baffle 3 and a bottom baffle 4 and a hollow support section 5; the two ends of the support section 5 are open, and the top baffle 3 is fastened on the top of the support section 5 to seal the top of the support section 5, and the bottom baffle 4 is fastened on the support The bottom of the section 5, the central opening of the bottom baffle 4, the bottom baffle 4 and the top baffle 3 are provided with several bolt holes 6, the bolt holes 6 of the bottom baffle 4 are evenly distributed along the central opening, The lightweight material layer 2 is covered on the outside of the supporting section 5 . The central steel structure 1 is welded by steel, and the center is a hollow structure. The thickness of the steel plate is determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com