Radially embedded maintenance-free shaft sleeve made of self-lubricating material

A maintenance-free and self-lubricating technology, which is applied in the direction of bearing components, shafts and bearings, bearing assembly, etc., can solve the problems of cumbersome and complicated operation and reduce work efficiency, and achieve the effect of simple and convenient operation, high work efficiency and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

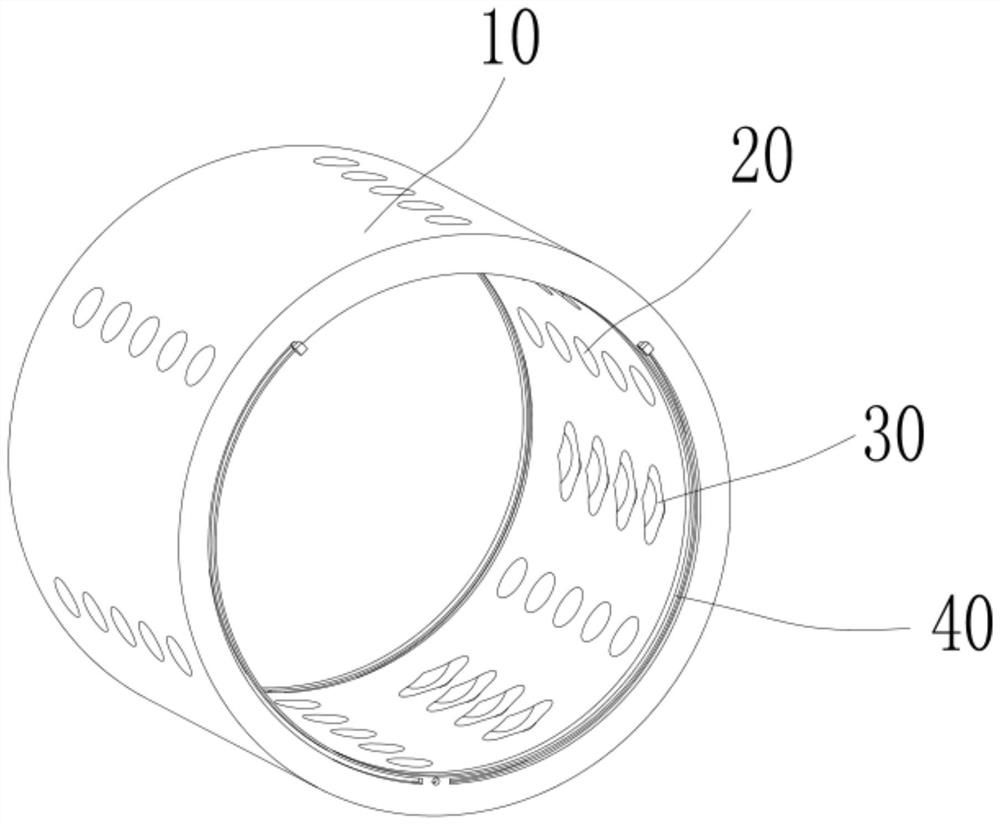

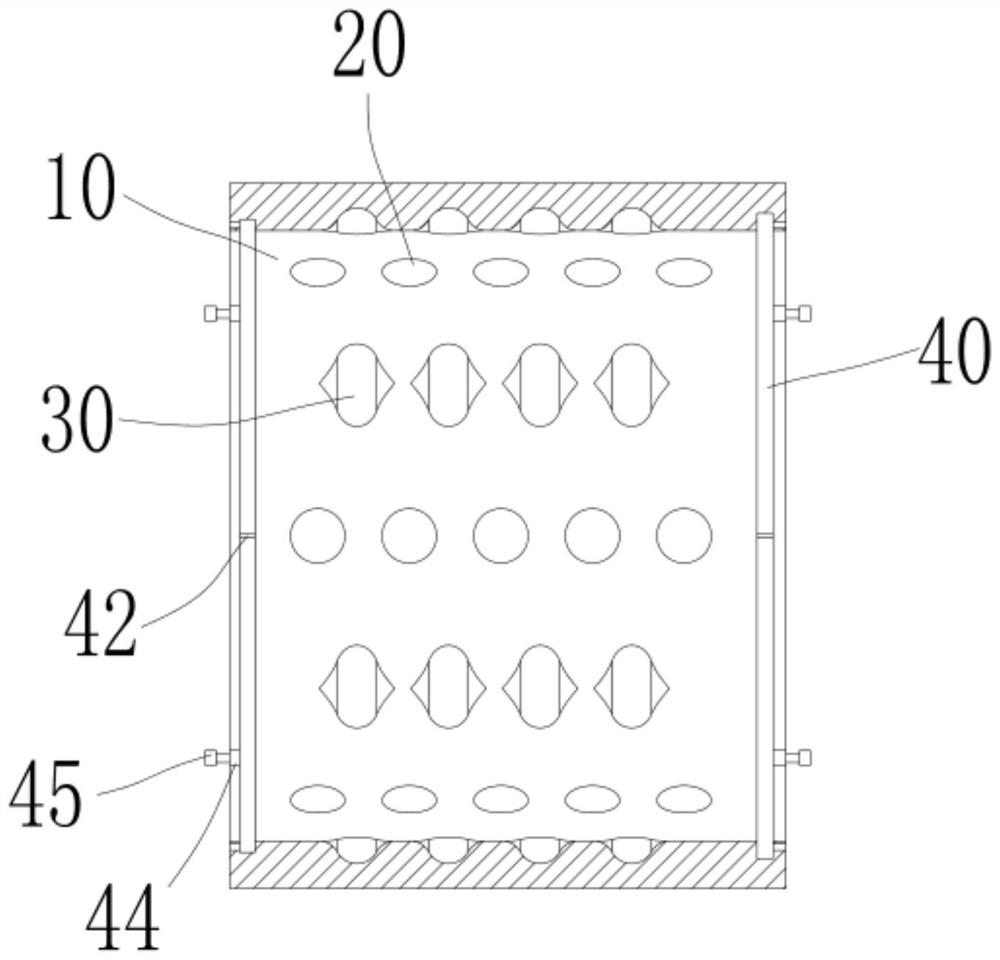

[0030] A radially embedded self-lubricating material maintenance-free bushing, including a bushing base 10, a plurality of groups of through holes 20 evenly distributed on the wall of the bushing base 10, the through holes 20 are filled with solid self-lubricating medium, the inner wall of the bushing base 10 Several groups of diversion oil grooves 30 are evenly distributed, and the diversion oil grooves 30 are filled with grease lubricant;

[0031] The solid self-lubricating medium has a microporous structure, and the solid self-lubricating medium automatically overflows a small amount of liquid lubricating oil during the heating process of the shaft sleeve for oil lubrication;

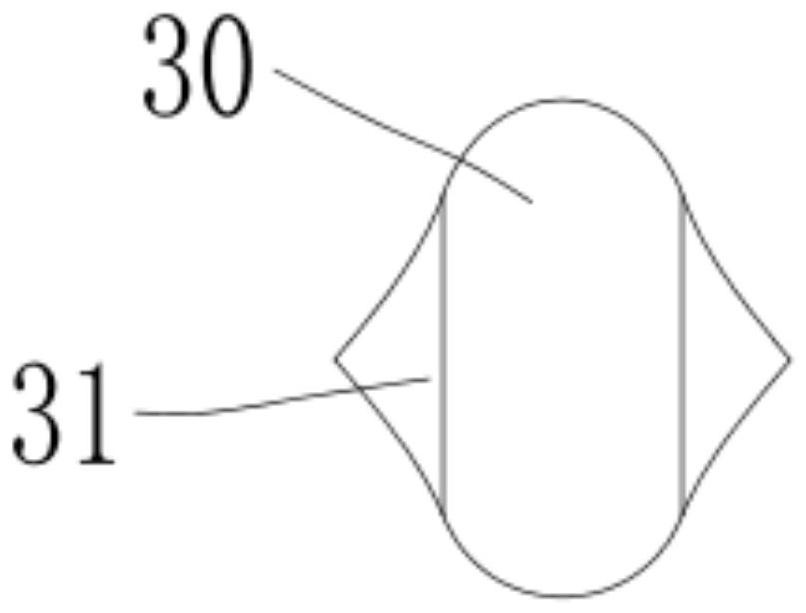

[0032] The diversion oil groove 30 is viewed as a waist-shaped groove from above, and the depth of the diversion oil groove 30 gradually decreases from the middle to both ends, until both ends of the diversion oil groove 30 extend to the inner wall of the sleeve base 10;

[0033] Both sides of the di...

Embodiment 2

[0038] Garbage ring grooves 40 are provided on the inner walls at both ends of the shaft sleeve base 10 .

[0039] Specifically, it can make the shaft sleeve and the shaft work together to isolate the garbage on the shaft body, so that the garbage on the shaft body can enter the garbage ring groove 40, avoid being squeezed into the matching gap between the shaft and the shaft sleeve, and ensure normal operation. .

Embodiment 3

[0041] Miscellaneous outlets 41 are respectively arranged on both ends of the shaft sleeve base 10, and the miscellaneous outlets 41 communicate with the garbage ring groove 40;

[0042] The garbage chute is provided with a miscellaneous discharge mechanism, which includes a connecting plate 42, an arc groove 43, an arc spring 46, a miscellaneous pushing plate 44 and a push handle 45, and the garbage ring groove 40 is far away from the miscellaneous discharge port 41 at the maximum distance. One end is provided with a connecting plate 42, and two groups of arc-shaped grooves 43 are arranged symmetrically on the end surface of the shaft sleeve base 10. The two groups of arc-shaped grooves 43 take the connecting plate 42 as a symmetrical plane, and the two sides of the connecting plate 42 are provided with miscellaneous pushing plates 44. Push miscellaneous plate 44 bottom edge and side contact with rubbish ring groove 40 inner walls, be provided with arc spring 46 between miscel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com