Cleaning device for sweet potato vermicelli processing

A cleaning device, potato flour technology, applied in the direction of using liquid cleaning method, dry gas layout, lighting and heating equipment, etc., can solve the problems of low efficiency, labor-intensive, etc., to save water resources, facilitate transportation and transfer, design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

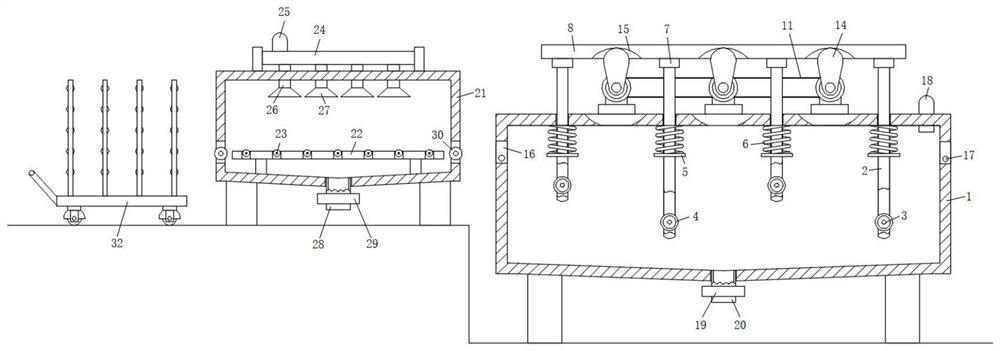

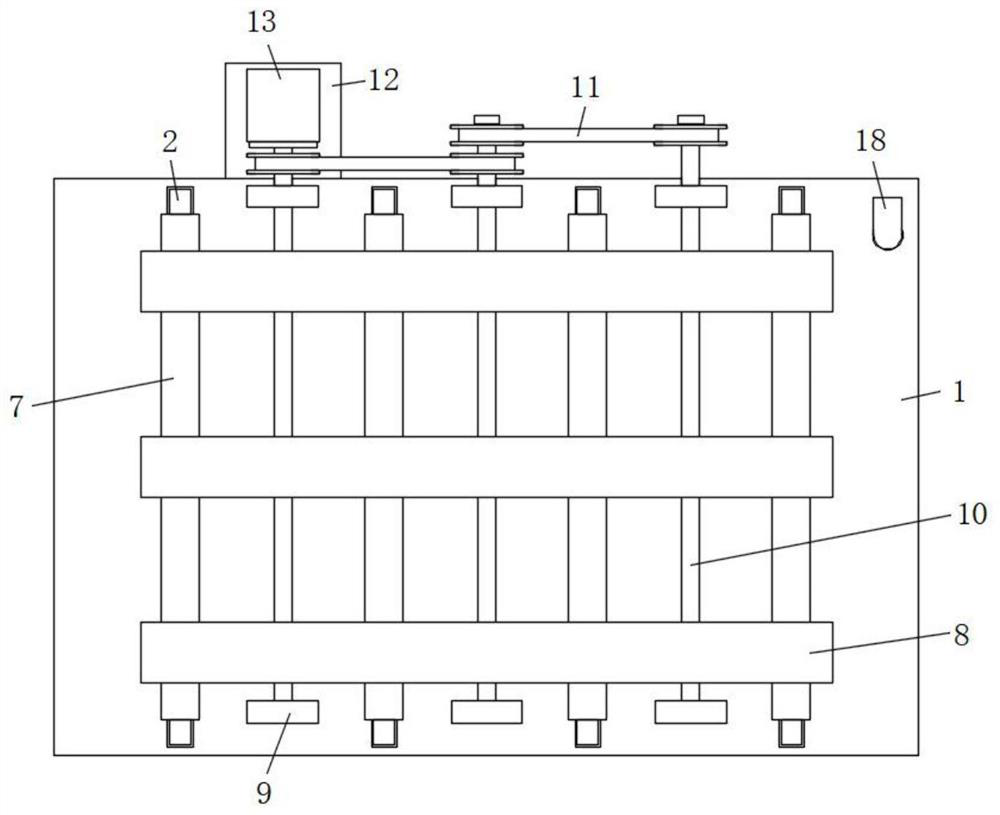

[0031] refer to Figure 1-5 , a cleaning device for processing sweet potato noodles, comprising a cleaning dish 1, the top surface of the cleaning dish 1 is slidably connected with a pressure rod 2, and the lower ends of the two pressure rods 2 in the same group are rotatably connected with a rotating rod 3, and the outer wall of the rotating rod 3 is connected by a screw The limit roller 4 is fixedly connected, and the outer wall of the upper end of the rotating rod 3 is fixedly connected with the limit ring 5, and the squeeze spring 6 is fixedly connected between the upper end of the limit ring 5 and the inner top surface of the cleaning dish 1, and two pressure rods 2 in the same group A connecting plate 7 is also fixed on the top of the connecting plate 7, and a horizontal plate 8 is also fixedly connected to the top of the connecting plate 7. Mounting seats 9 are arranged between adjacent two connecting plates 7, and between two mounting seats 9 on the same vertical surfac...

Embodiment 2

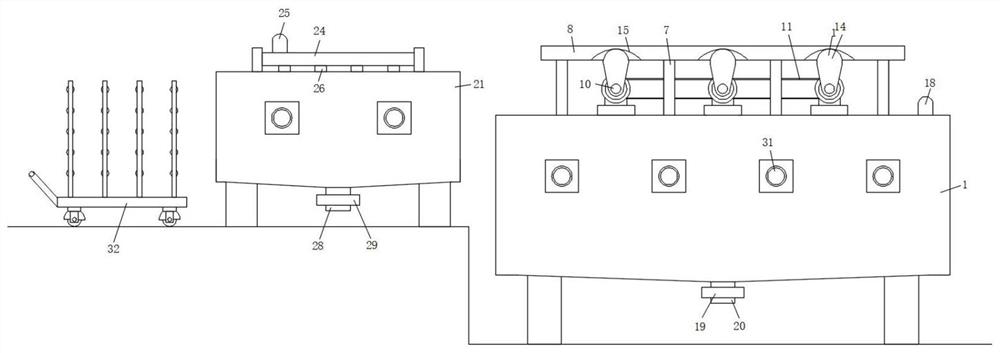

[0034] Such as figure 1 , 2 As shown in and 5, this embodiment is basically the same as Embodiment 1. Preferably, the collection assembly 32 includes a bottom plate 321, universal wheels are installed at the four corners of the bottom surface of the bottom plate 321, and vertical wheels are fixedly connected to the front and rear sides of the bottom plate 321. Plate 322, hanging rod 323 is fixed between the two vertical plates 321 on the same vertical position, and a push handle 324 is also welded on one side of the bottom plate 321.

[0035] The vertical boards 322 are provided with multiple pieces and evenly distributed in groups on the top surface of the bottom board 321 , and the hanging rods 323 are provided with multiple pieces and evenly distributed between the two vertical boards 322 in the same group.

[0036] In this embodiment, a plurality of hanging rods 323 are arranged between the two vertical plates 322 in the same group, so that it is more convenient to hang b...

Embodiment 3

[0038] Such as figure 1 and 3 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, a plurality of pressing rods 2 are arranged and evenly distributed in groups on the cleaning dish 1, and each group of pressing rods 2 is provided with two and symmetrically distributed on the cleaning dish 1. At the front and rear positions of the dish 1, a plurality of limit rollers 4 are arranged alternately.

[0039] In this embodiment, a plurality of pressing rods 2 are provided and evenly distributed in groups on the cleaning dish 1, thereby increasing the contact range between the vermicelli and water, thereby ensuring the cleaning quality of the vermicelli.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com