Rotary excess material removing device for ceramic bowls

A ceramic bowl, rotary technology, used in grinding drives, cleaning hollow objects, cleaning methods and utensils, etc., can solve problems such as low efficiency and slow speed, and achieve the effect of reducing complexity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

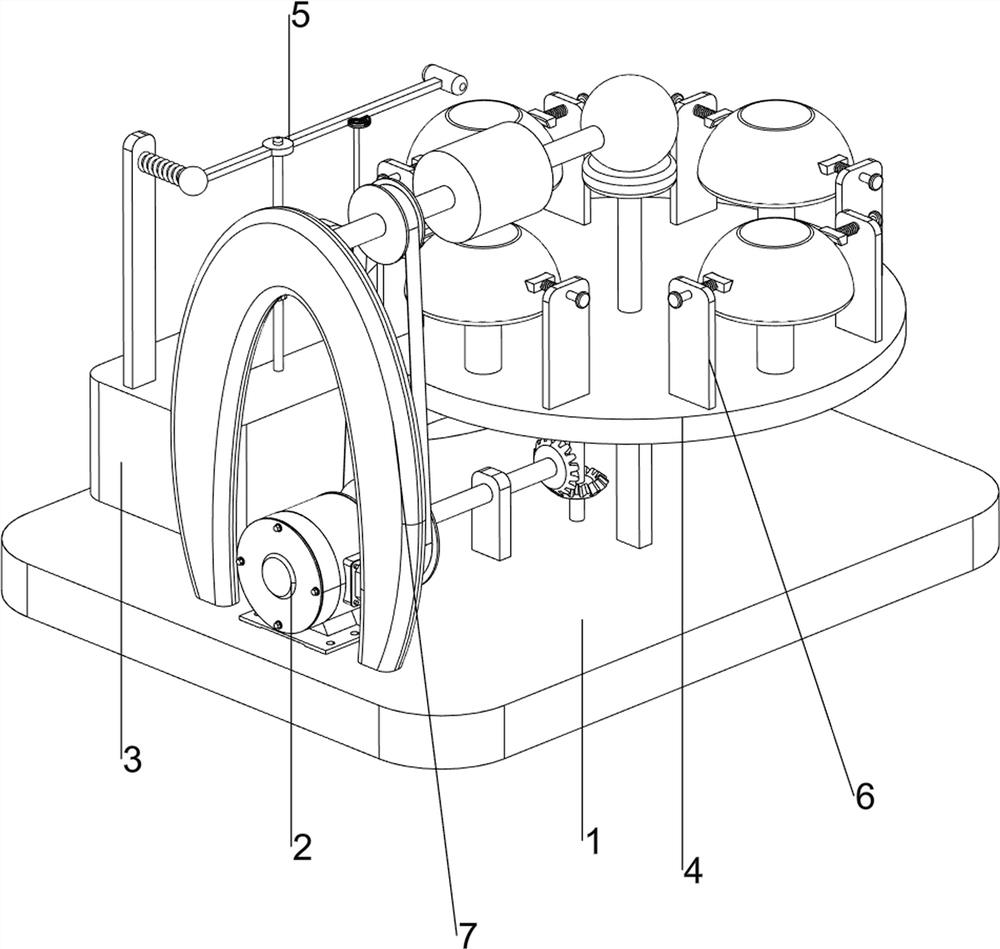

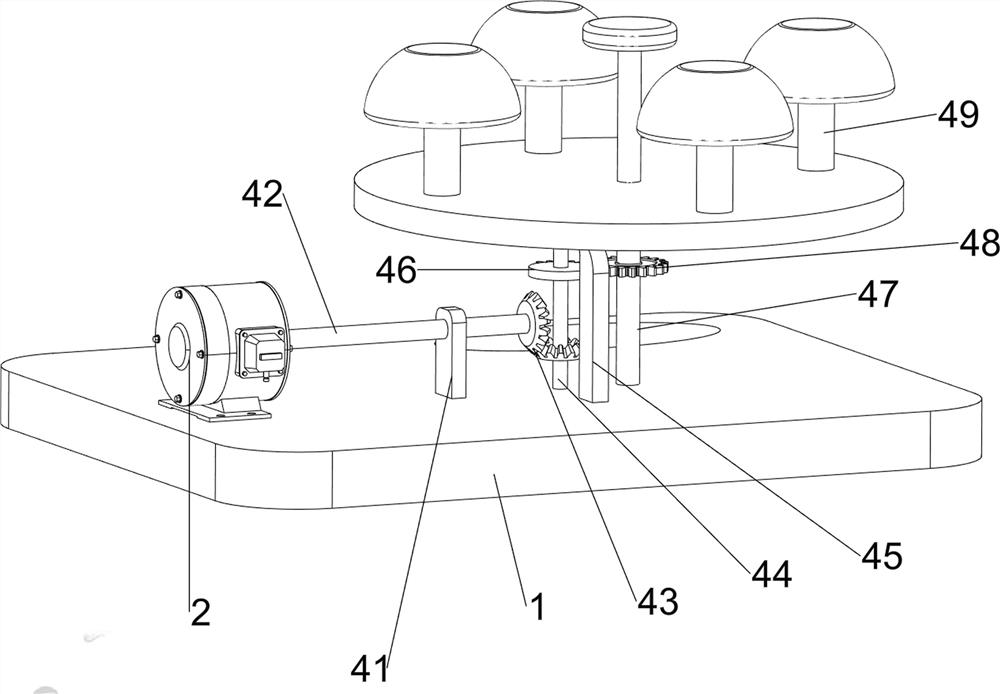

[0022] A kind of rotating type ceramic bowl removes excess material device, such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Shown, comprise base 1, motor 2, cushion block 3, rotating mechanism 4 and beating mechanism 5, motor 2 is installed on the front side on base 1, cushion block 3 is provided on the left side on base 1, rear side is provided with on base 1 Rotating mechanism 4 is arranged, and rotating mechanism 4 is connected with motor 2 output shafts, and pad 3 upper side is provided with beating mechanism 5, and beating mechanism 5 is connected with rotating mechanism 4.

[0023] When people remove excess materials from ceramic bowls, it is impossible to achieve more convenient and more efficient removal of materials by relying on existing methods to remove excess materials from ceramic bowls. Therefore, people can use this device to remove excess materials from ceramic bowls. People prepare ceramic bowls that need to be removed, and then place t...

Embodiment 2

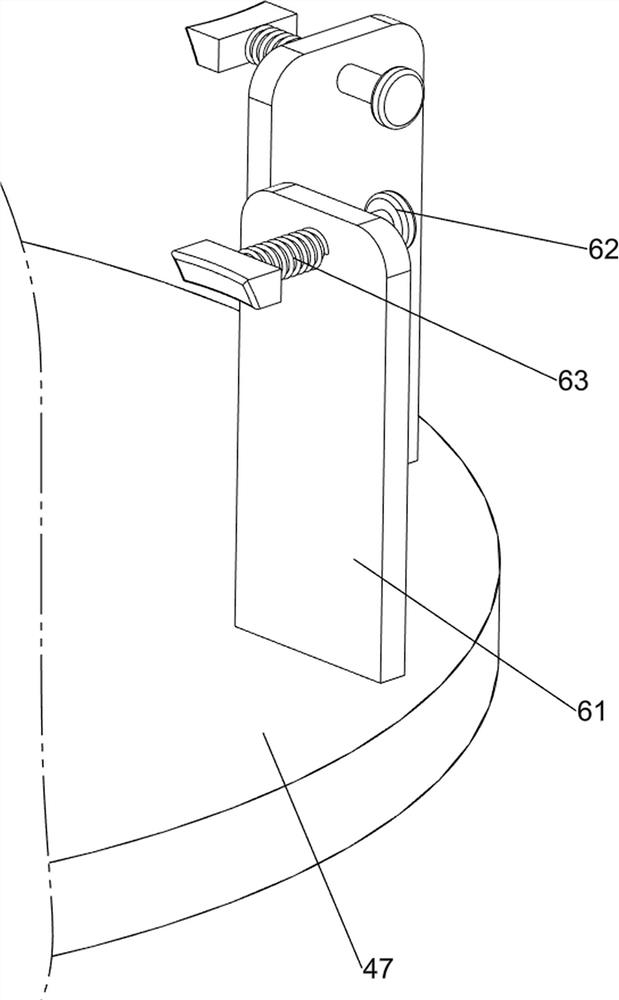

[0029] On the basis of Example 1, such as figure 1 , Figure 4 with Figure 5 As shown, a clamping mechanism 6 is also included, and the clamping mechanism 6 includes a fifth support frame 61, a pressure block 62 and a second spring 63, and eight fifth support frames 61 are arranged on the rotating disc 47, each two The fifth support frame 61 is a group, and the fifth support frame 61 of every group is symmetrically distributed, and the inner side of the upper part of the two fifth support frames 61 of each group is provided with a pressure block 62 slidingly, and a second spring 63 is wound on the pressure block 62 , the second spring 63 is connected with the fifth supporting frame 61 and the pressure block 62 .

[0030] When people prepare the ceramic bowls that need to remove the remaining materials, they first turn the ceramic bowls manually, then press down the turned ceramic bowls along one set of briquetting blocks 62, and the ceramic bowl walls squeeze the briquettin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap