Simple automatic knife sharpening device

A simple and automatic knife sharpening technology, applied in grinding/polishing equipment, grinding/polishing manual tools, metal processing equipment, etc., can solve problems such as low efficiency, cumbersome process, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

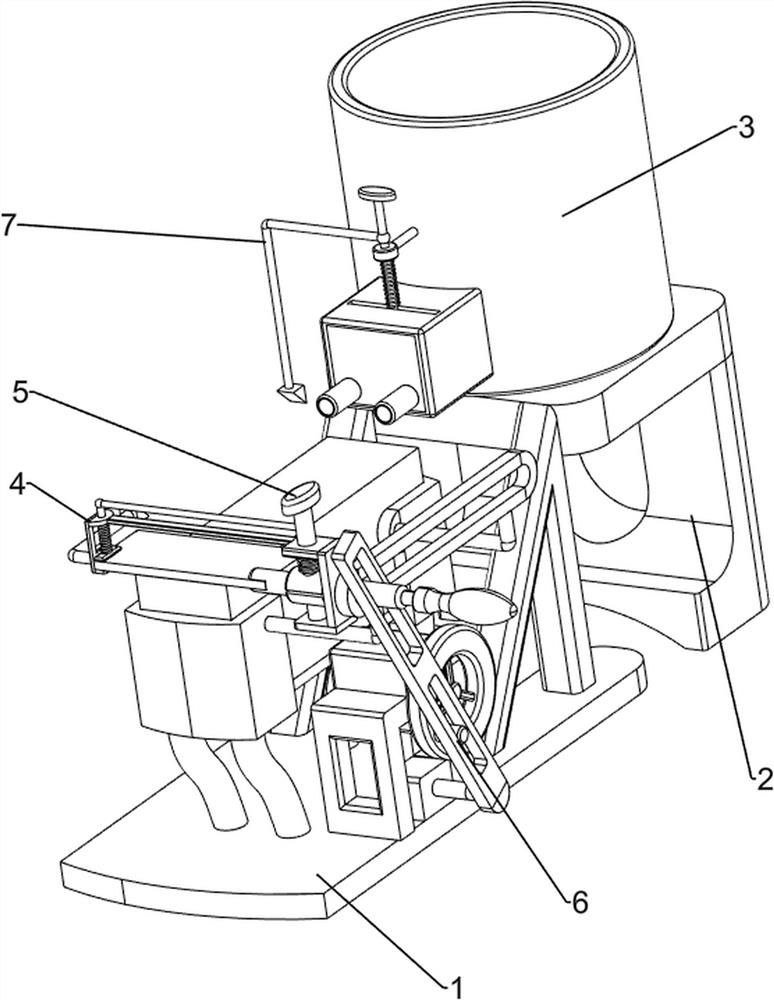

[0022] A simple automatic sharpening device, such as figure 1 As shown, it includes base 1, No. 1 pillar 2, water storage tank 3, pushing mechanism 4 and clamping mechanism 5. Base 1 and No. 1 pillar 2 are placed on the ground, and the top rear end of base 1 and the top front end of No. 1 pillar 2 Fixedly connected, a water storage tank 3 is installed at the end of No. 1 pillar 2, a pushing mechanism 4 is provided on the right side of the bottom of the base 1, and a clamping mechanism 5 is arranged in the middle of the bottom of the base 1, and the pushing mechanism 4 cooperates with the clamping mechanism 5.

[0023] The worker first manually pulls the clamping mechanism 5 upwards, and the worker needs to put the knife in the clamping mechanism 5. When the knife is placed in the clamping mechanism 5, the worker releases the clamping mechanism 5, and the clamping mechanism 5 will clamp the knife The worker manually pulls the pushing mechanism 4 forward and backward, and the re...

Embodiment 2

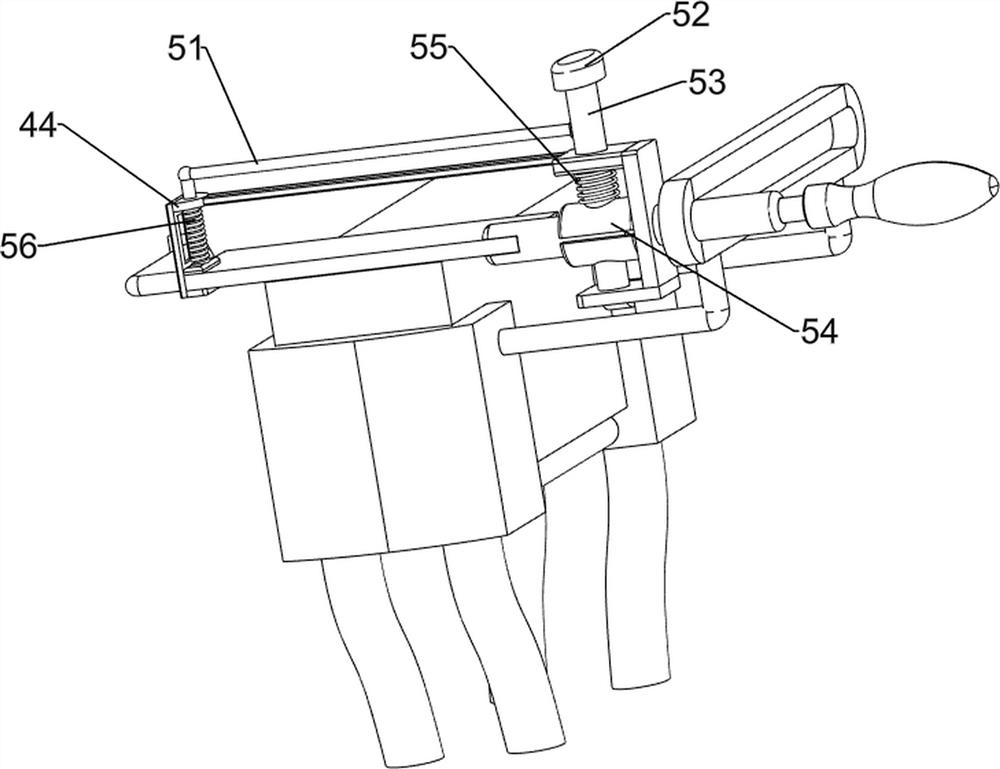

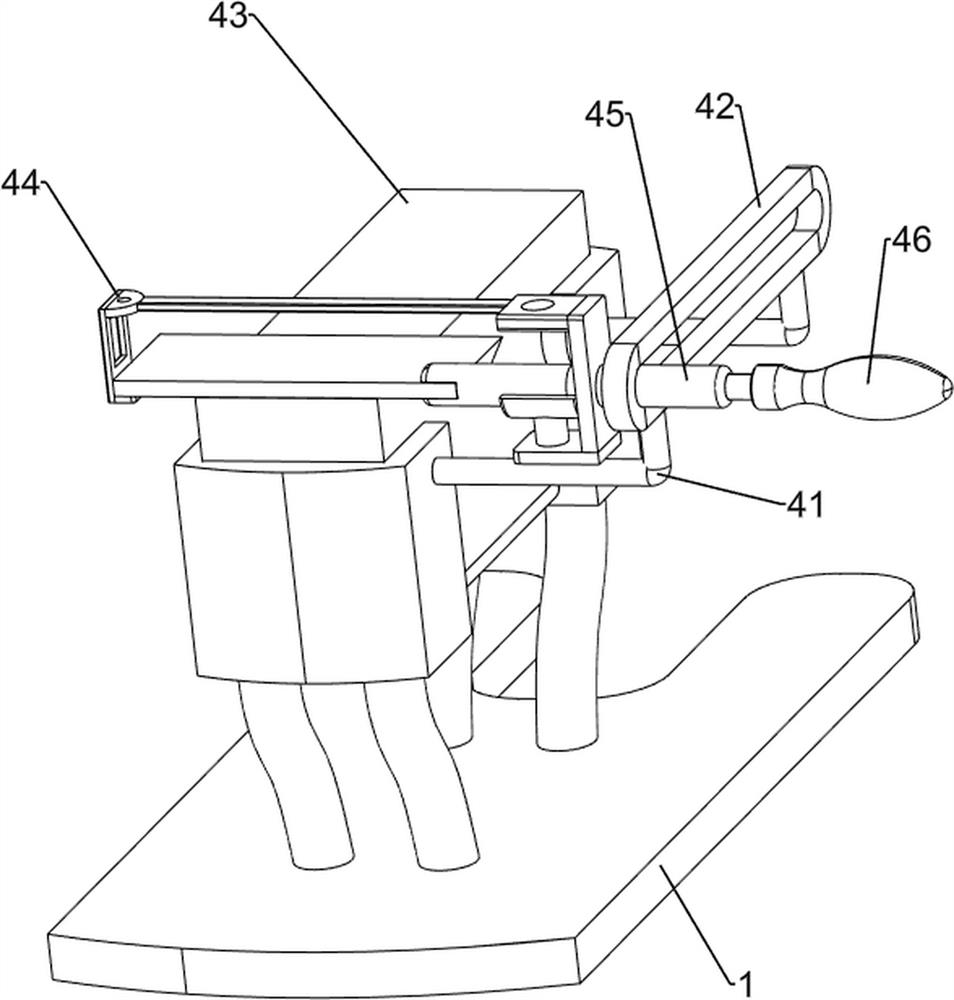

[0025] In a preferred embodiment of the present invention, as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the pushing mechanism 4 includes a No. 1 support 41, guide rail 42, whetstone 43, fixed frame 44, No. 1 push rod 45 and handle 46. The right side of the base 1 top is symmetrically provided with No. 1 support 41, two No. 1 supports 41 tops are connected with guide rail 42, base 1 top is placed with whetstone 43, slide type is provided with No. 1 push rod 45 in guide rail 42, fixed frame 44 is installed on the left side of No. 1 push rod 45, and No. 1 push rod 45 right side A handle 46 is provided on the side.

[0026] The worker needs to put the knife in the clamping mechanism 5. The worker manually pushes the handle 46 to move backward. The backward movement of the handle 46 will drive the No. 1 push rod 45 to move backward in the guide rail 42, and the No. 1 push rod 45 will move backward to the clamp The knife in the tightening mechanism 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com