Indirect evaporation cooling and heat pipe dual-power combined system and control method

A combined system and evaporative cooling technology, applied in heating methods, air conditioning systems, space heating and ventilation, etc., can solve problems affecting the reliability of equipment in the computer room, increase the maintenance cost of the computer room, and high energy consumption of computer room air conditioners, and achieve the goal of providing and utilizing Efficiency, structure simplification, and power saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

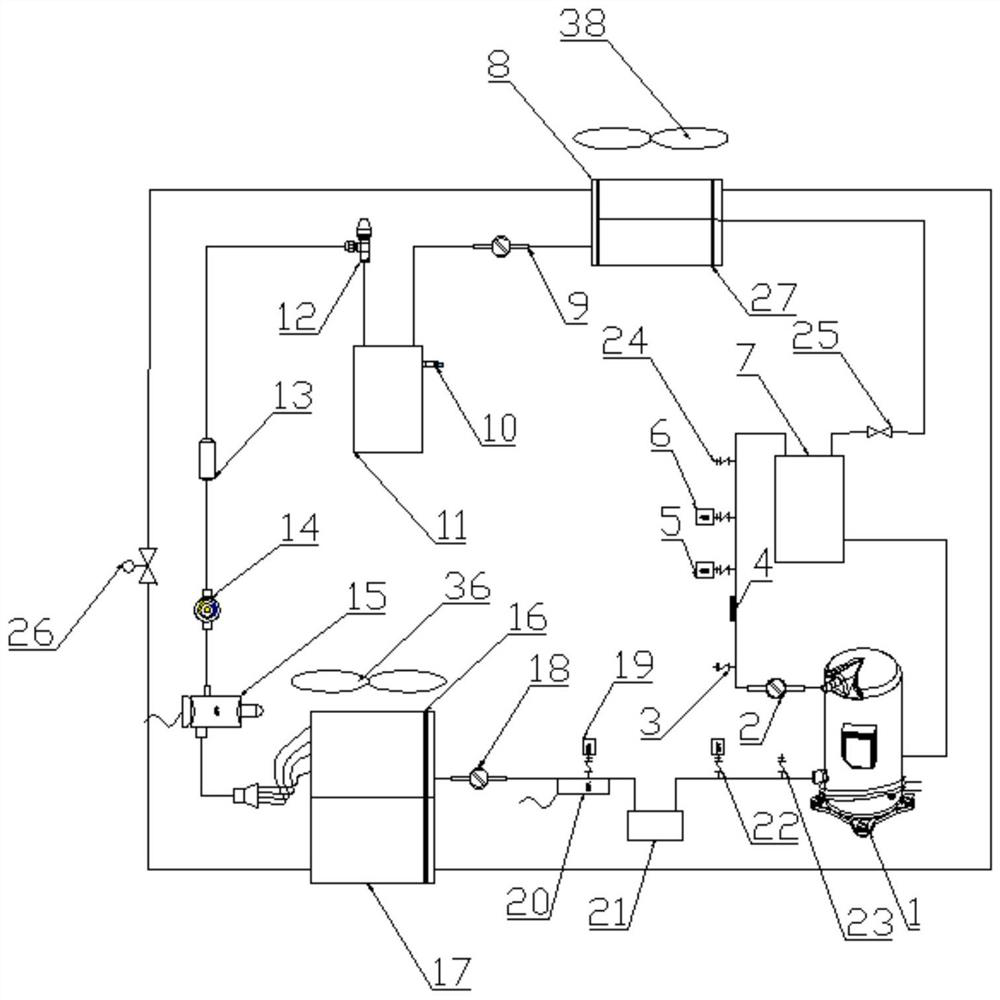

[0039] This embodiment provides an indirect evaporative cooling and heat pipe dual power combined system, which is composed of an indirect evaporative cooling system and a DX-heat pipe compensation system; wherein, the DX heat pipe compensation system includes a DX compensation system and a gravity heat pipe system, an indirect evaporative cooling system, The start-stop mechanisms of the DX compensation system and the gravity heat pipe system are independently controlled, and the three systems are coupled to form the dual power combined system of indirect evaporative cooling and heat pipe in this embodiment.

[0040] The three-system coupling structure is: the DX compensation system includes a DX evaporator 16, and the gravity heat pipe system includes a heat pipe evaporator 17 and a heat pipe condenser 8; the DX evaporator 16 and the heat pipe evaporator 17 are installed indoors, and both share indirect evaporation The indoor air supply fan 36 of the cold system; the heat pipe...

Embodiment 2

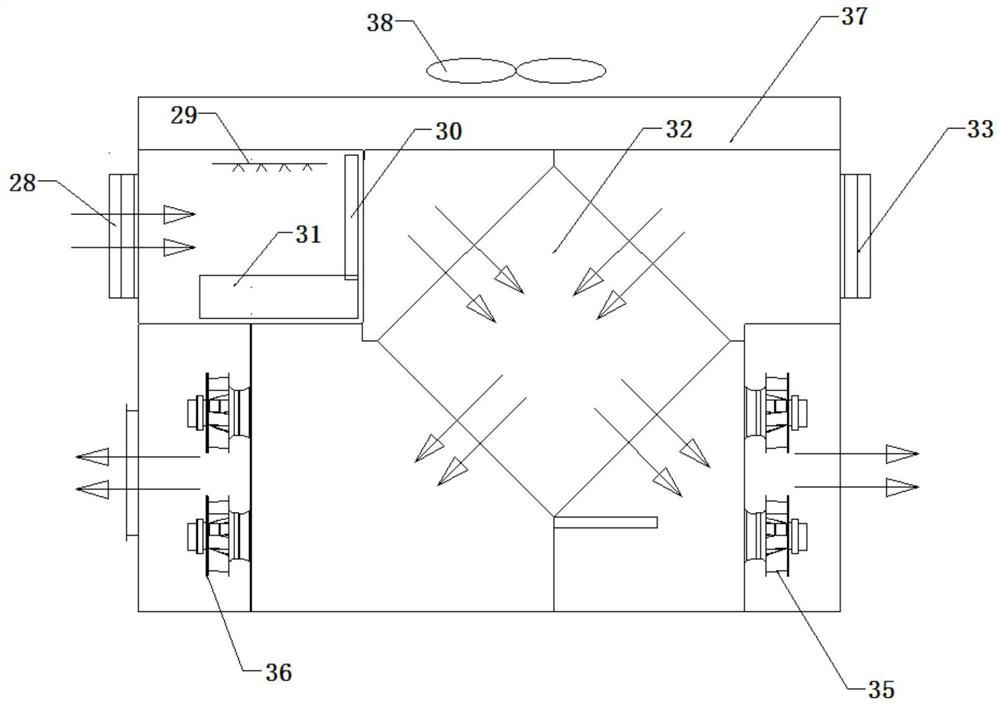

[0045] Further improvement on the basis of Embodiment 1, the indirect evaporative cooling system includes a shell, and the shell is provided with an outdoor air return port 28, an outdoor air supply fan 35, an indoor air return port 33 and an indoor air supply fan 36; There is an air-to-air heat exchanger 32 . The return air from the outdoor return air outlet 28 enters the air-to-air heat exchanger 32 through the outdoor air passage, and is sent to the outside through the outdoor air passage and the outdoor air supply fan 35 in turn after heat exchange; the return air from the indoor return air outlet 33 enters the air-to-air heat exchanger through the indoor air passage 32. After the heat exchange, it is sent into the room through the indoor air channel and the indoor air supply fan 36 in turn; A spray device 29 is provided at the outdoor air return port 8, and a water-repelling wet film 30 is also provided on the downwind indoor air channel after the outdoor air return port ...

Embodiment 3

[0047] This embodiment provides a dual power combined control method for indirect evaporative cooling and heat pipes, using the dual power combined system of indirect evaporative cooling and heat pipes used in Embodiment 2; according to the outdoor dry bulb temperature and outdoor wet bulb temperature, start the indirect Any system or a combination of systems in evaporative cooling system, DX compensation system and gravity heat pipe system.

[0048] Include the following steps:

[0049] When the outdoor dry bulb temperature is -5<T<16°C, run the indirect fresh air cooling mode and start the indirect evaporative cooling system for cooling alone;

[0050] When the outdoor dry bulb temperature is T>16°C and the outdoor wet bulb temperature is T 0 When <16°C, run the indirect evaporative cooling mode, start the indirect evaporative cooling system alone, and the outdoor return air is first cooled directly by spraying, and then indirectly cooled by the indirect evaporative cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com