Bionic non-pneumatic tire

A non-pneumatic tire and tread technology, which is applied to non-pneumatic tires, tire parts, transportation and packaging, etc., can solve the problems of poor shock absorption performance and loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

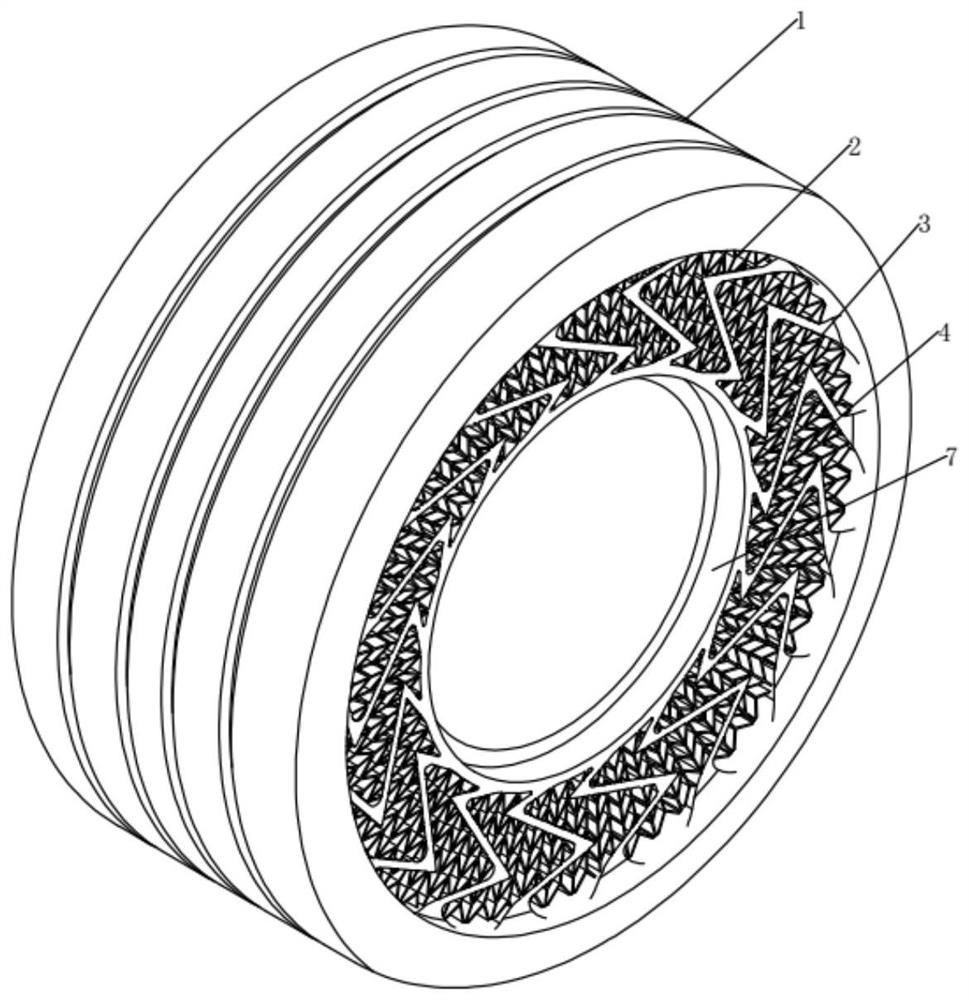

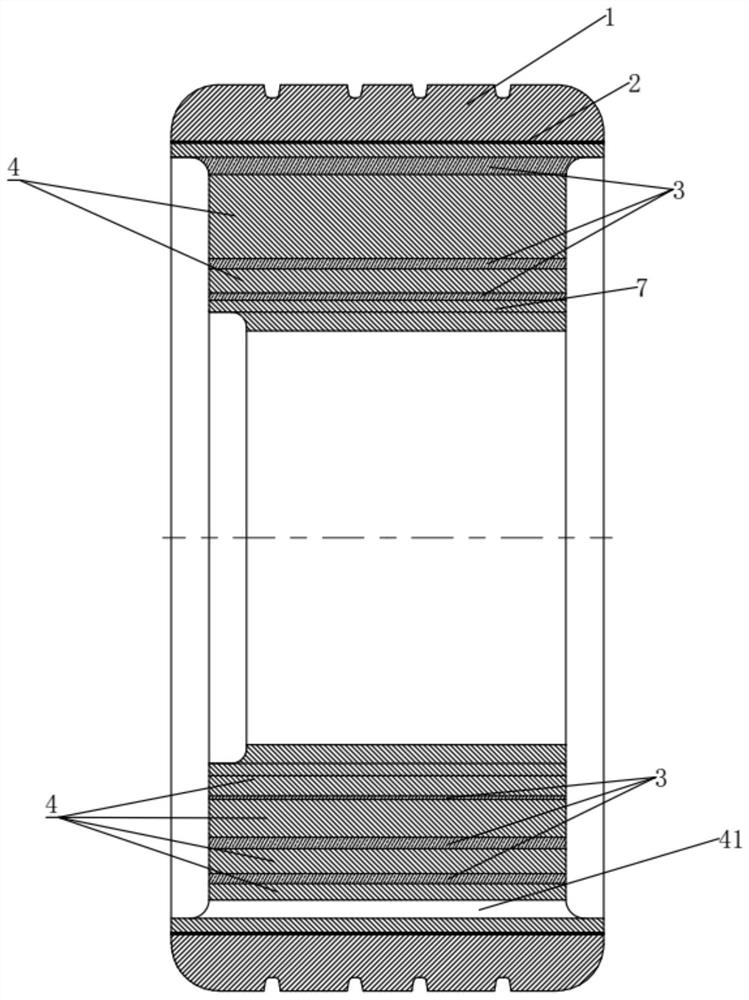

[0028] Such as figure 1 As shown, a bionic air-free tire includes a tread 1, a connecting layer 2, a bionic cushioning structure and an installation body 7 from outside to inside in sequence, and the above-mentioned parts are closely connected to form a whole. The tread 1 is directly in contact with the ground, and its surface is provided with tire patterns. The tread 1 is preferably a nano-rubber layer. The connecting layer 2 is an adhesive material, which tightly connects the tread 1 with the bionic buffer structure. The installation body 7 is an installation part of the tire, and the bionic tire is fixedly connected with the vehicle through the installation body 7 .

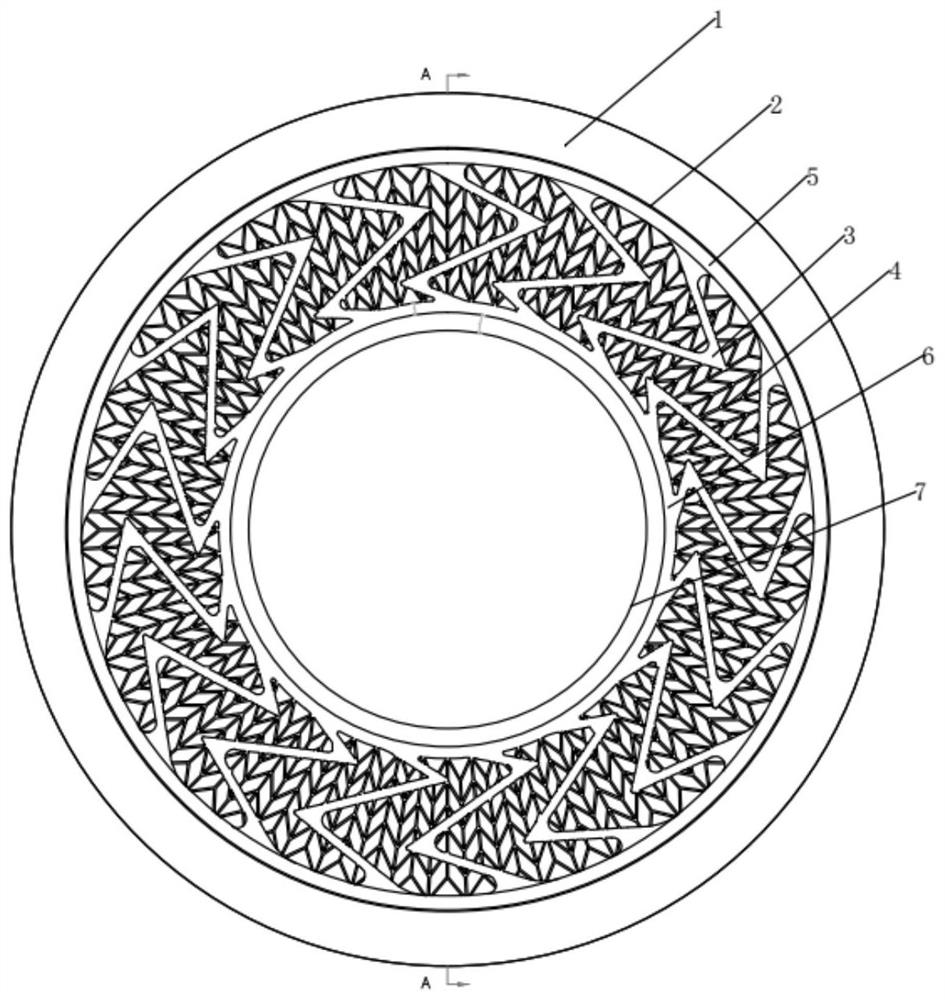

[0029] Such as figure 2 As shown, the bionic buffer structure is composed of a Z-shaped buffer plate 3 imitating the hind limbs of a cat, a diamond-shaped honeycomb elastic body 4 , a first outer ring 5 and a first inner ring 6 . The first outer ring 5 is set close to the connection layer 2, the first inn...

Embodiment 2

[0036] Such as Figure 5 As shown, a bionic air-free tire includes a tread, a connecting layer, a bionic buffer structure, an adaptive buffer structure and an installation body in sequence from outside to inside. Compared with Example 1, the bionic air-free tire has an adaptive buffer structure added.

[0037] The tread, connecting layer and adaptive cushioning structure are similar to those in Embodiment 1.

[0038] Such as Figure 6 As shown, the adaptive buffer structure is composed of an I-shaped buffer plate 8, a second outer ring 9 and a second inner ring 10, the second outer ring 9 is close to the first inner ring 6, and the second inner ring 10 is close to the mounting body 7 , an annular area is formed between the second outer ring 9 and the second inner ring 10, the I-shaped buffer plate 8 is radially distributed in the annular area along the second inner ring 10, and the I-shaped buffer plate 8 is relatively to the second inner ring The ring 10 is arranged obliqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com