Feeding method and multi-channel feeding machine

A feeder, multi-channel technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of easy sticking together, difficult to divide materials, and difficult to use automatic equipment to supply materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

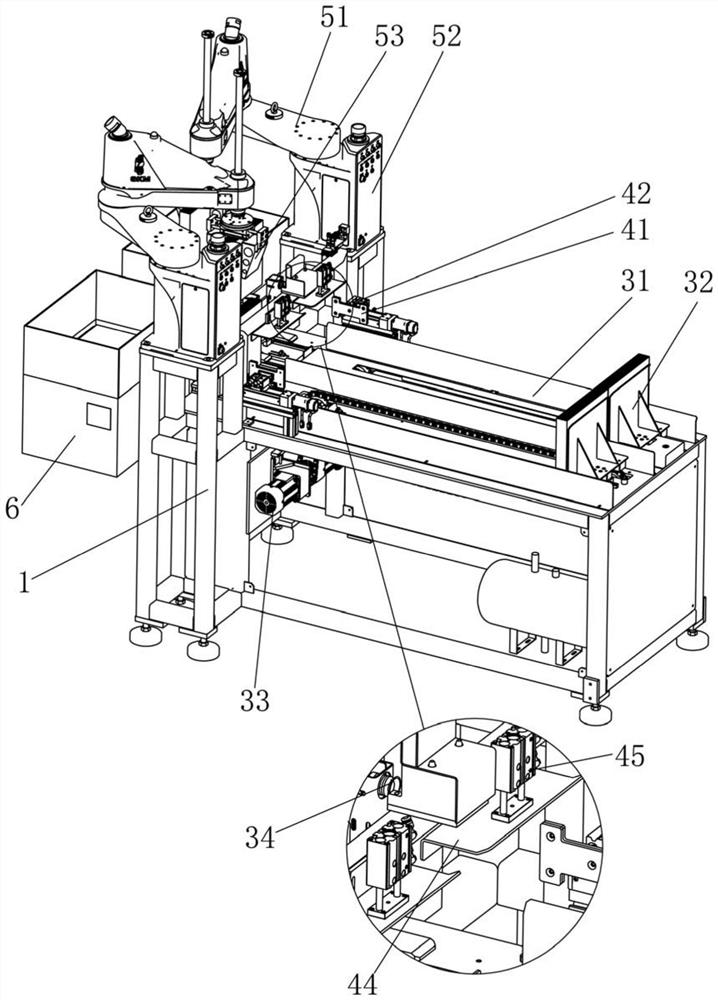

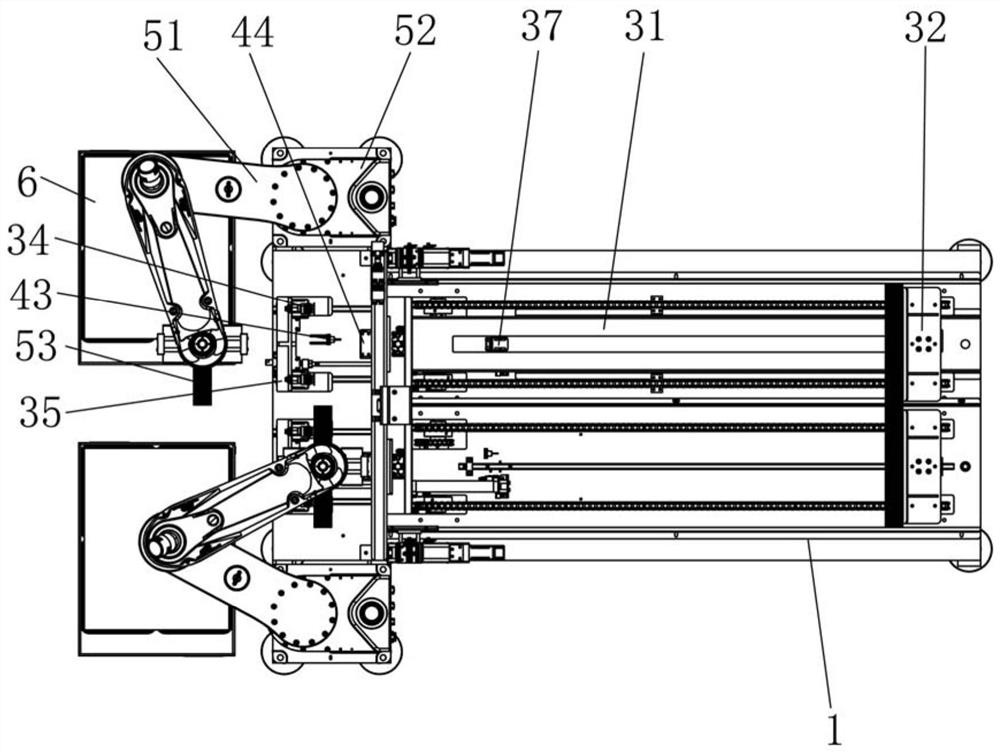

Embodiment 1

[0030] This embodiment provides a material feeding method, which includes the following steps in sequence: S1: setting a predetermined vacuum value; S2: pushing a plurality of materials that are stacked one after another away from the suction cup 34, so that the materials closest to the suction cup 34 collide with the suction cup 34 To be adsorbed by the suction cup 34, and detect the vacuum value in the suction cup 34 during the pushing process; S3: When it is detected that the vacuum value in the suction cup 34 is equal to the predetermined vacuum value set in S1, stop pushing the stacked multiple materials; S4: fix the material next to the suction cup 34; S5: move the suction cup 34 to separate the material closest to the suction cup 34 from the material next to the suction cup 34.

[0031] The purpose of detecting the vacuum value in the suction cup 34 in step S2 is to detect whether the suction cup 34 has adsorbed the material stably. Since the suction cup 34 has differen...

Embodiment 2

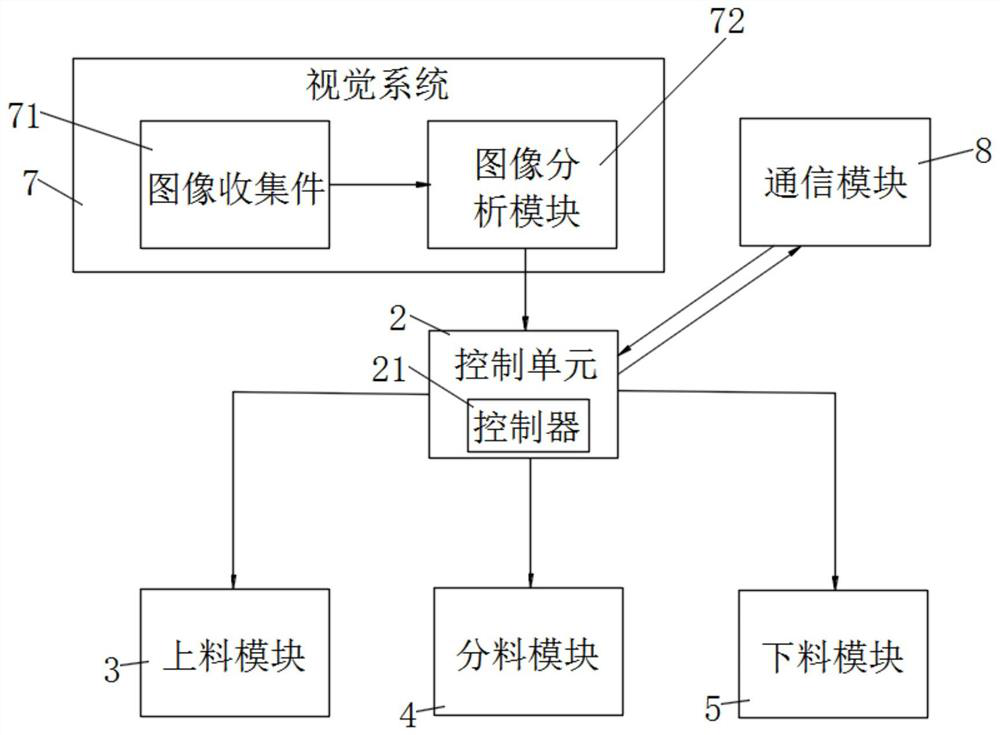

[0038] The difference between this embodiment and the first embodiment is that in step S1, the materials of the plurality of materials are detected, and pre-stored values are selected in the database according to the detection results, and the predetermined vacuum value is set with the selected pre-stored values. This can reduce manual operations and further improve the automation of the entire feeding process. Specifically, a CCD camera or other image acquisition equipment may be used to collect the image of the material, and then an image analysis technology may be used to analyze the material of the material.

Embodiment 3

[0040] The difference between this embodiment and the first embodiment is that in step S1, the server remotely sets the preset vacuum value through the communication module 8 . This allows the user to remotely set the vacuum preset value using the server, thereby improving the convenience and efficiency of the feeding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com