Patents

Literature

50results about How to "To achieve the effect of feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monolithic multi-way valve body casting piece casting method

ActiveCN105903910ADefect control such as sticky sandAvoid overheatingFoundry mouldsFoundry coresCasting defectLinearity

The invention discloses a monolithic multi-way valve body casting piece casting method which comprises the following steps: preparing a core preparing mold, and checking and cleaning the mold; preparing a main core by mold sand, and after the shape of the main core is finalized, spraying a mold release agent, and demolding; preparing small cores, and drilling exhaust holes in the small cores; finishing to remove burrs on the main core and the small cores, and removing a transition jet nozzle on the main core; fixing the main core by a sand core bonding preparation tooling, firstly assembling the small core at one side, and then assembling the small core at the other side; mounting the assembled sand core into a shell body; and casting a valve body: performing a pouring process at two sides of a side thin gate at the same time, using an exothermic riser with the diameter of 120 mm and the height of 220 mm, and placing special cold iron at the bottom face of the shell body. The monolithic multi-way valve body casting piece casted by the casting method has the advantages that the linearity of a main valve hole casting blank is controlled to be less than or equal to 1.0 mm, and the valve hole linearity is ensured; the casting piece pore shrinkage, shrinkage porosity, internal gas holes and other casting defects, especially defects of micropores in the casting piece, are solved; and the compactness of the internal structure is improved.

Owner:南通华东油压科技有限公司

Efficient cleaning device for cable recycling

ActiveCN109290243AReasonable designCompact structureSolid separationBasic electric elementsEngineeringWater tanks

The invention provides an efficient cleaning device for cable recycling. The efficient cleaning device comprises a cleaning box, a plurality of supporting legs which are connected to the lower end ofthe cleaning box, first circular through holes formed in side walls of two ends of the cleaning box, cable bodies which are in sliding connection in the two first circular through holes, and a motor which is connected onto the inner top wall of the cleaning box through a first bracket. The efficient cleaning device overcomes the defects in the prior art, is reasonable in design, is compact in structure, drives a brush to rotatably clean the cable body through the motor, reduces manual operation, and improves the cleaning effect; meanwhile, automatic feeding can be realized by rotating a driverotary wheel, so that cleaning efficiency is improved; and water in a ring-shaped water tank can be sprayed onto the cable body through a driven rotary wheel, so that dirt is softened, and the cleaning effect is improved again, and therefore, the efficient cleaning device has very high practicability.

Owner:天长市运成电缆辅料有限公司

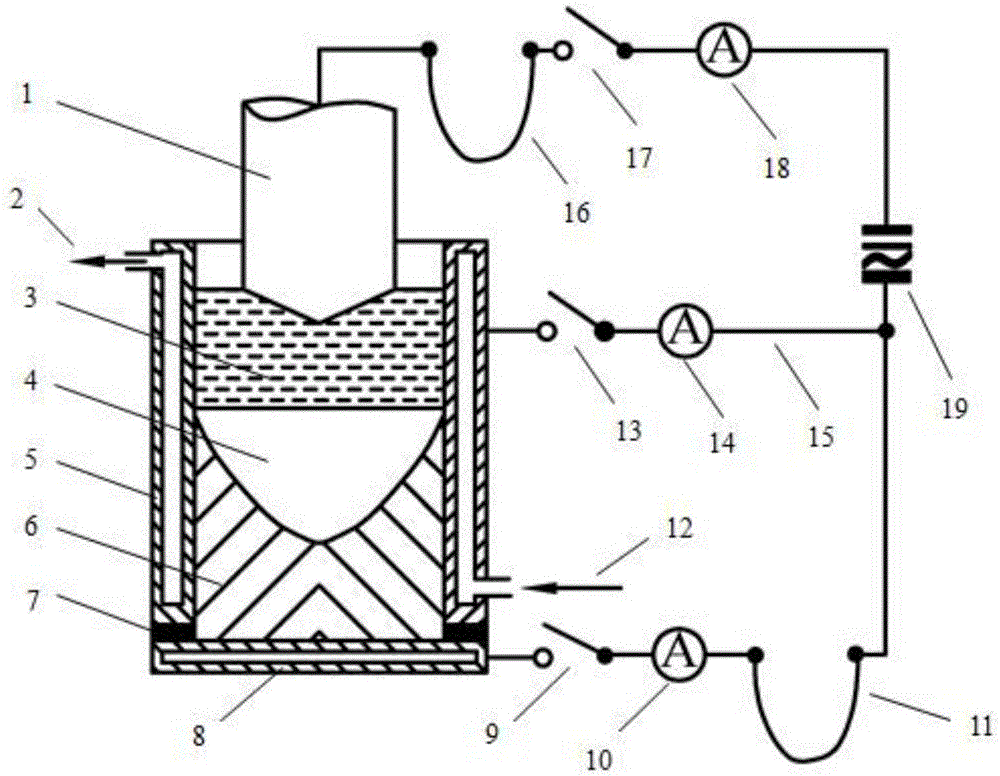

Method for controlling direction of solidification structure of cast ingot through electricity conductive crystallizer electroslag remelting

The invention discloses a method for controlling the direction of a solidification structure of a cast ingot through electricity conductive crystallizer electroslag remelting and belongs to the technical field of metallurgy. The method comprises the steps that (1) a slag material with the high conductivity is prepared and then baked; (2) the filling rate and the insertion depth of an electrode are determined, and a base wad, an arc striking agent and an electricity conductive crystallizer are right placed; and (3) a path of an electric current flowing through a power source, the consumable electrode, the slag material, a bottom water tank and the power source is selected, and arc striking, material charging and slag melting are conducted; after the slag material is melted down, a remelting electric current and the remelting voltage are set; the path of the electric current is set through closing of a switch in the electroslag remelting process, the distribution ratio of electric currents flowing through the crystallizer and the bottom water tank is controlled, the shape and the depth of a metallic molten pool are changed, and the direction of the solidification structure is controlled; and in the later period of remelting, electricity is cut off after electroslag remelting feeding operation, cooling is conducted, and the remelted cast ingot is obtained. According to the method for controlling the direction of the solidification structure of the cast ingot through electricity conductive crystallizer electroslag remelting, a slag system with the high conductivity distribution ratio is adopted, and the tendency of axial crystallization of the solidification structure of the cast ingot is improved; and the crystallization direction of the solidification structure of the cast ingot is controlled in the remelting process, and the prepared cast ingot has good surface quality.

Owner:NORTHEASTERN UNIV

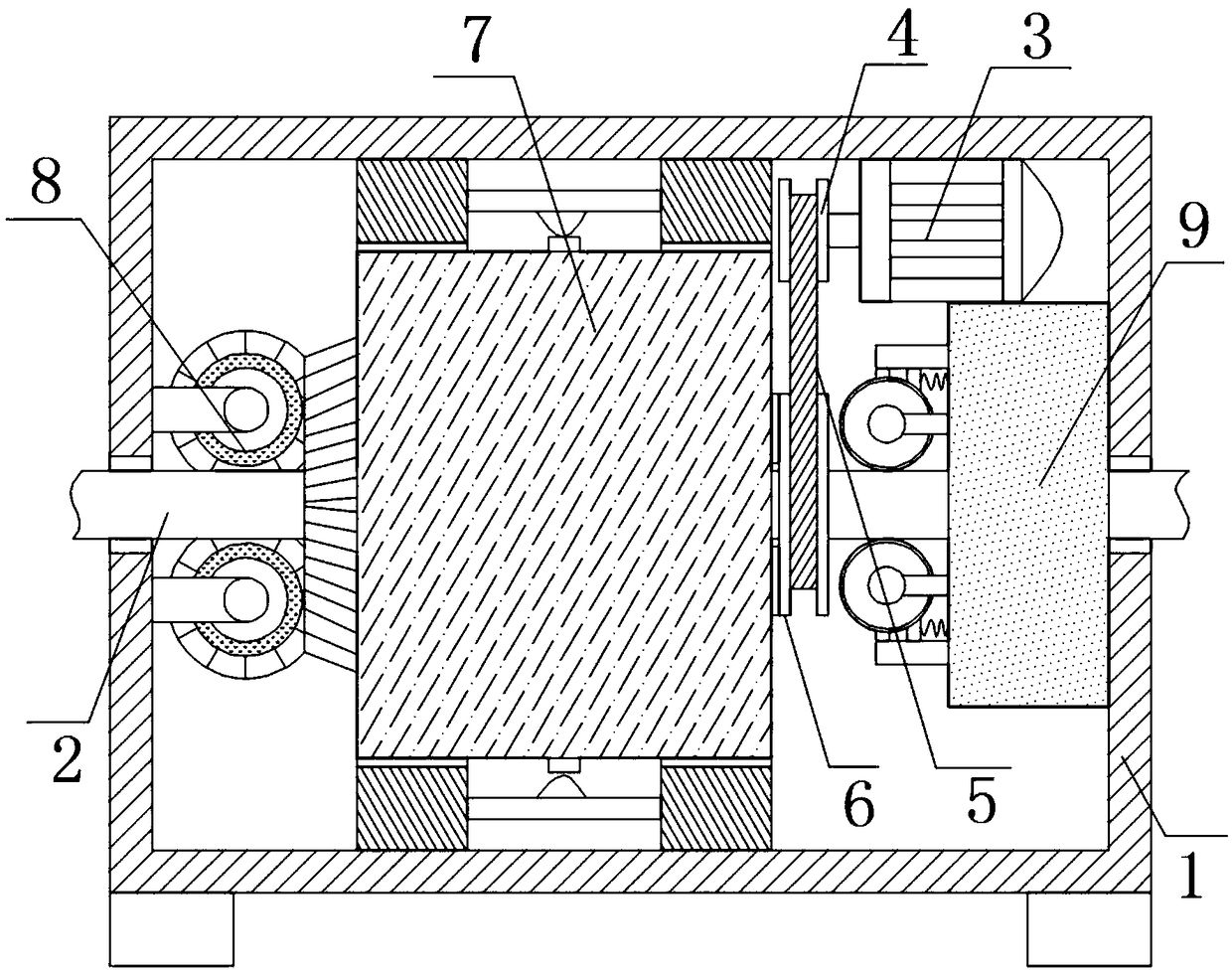

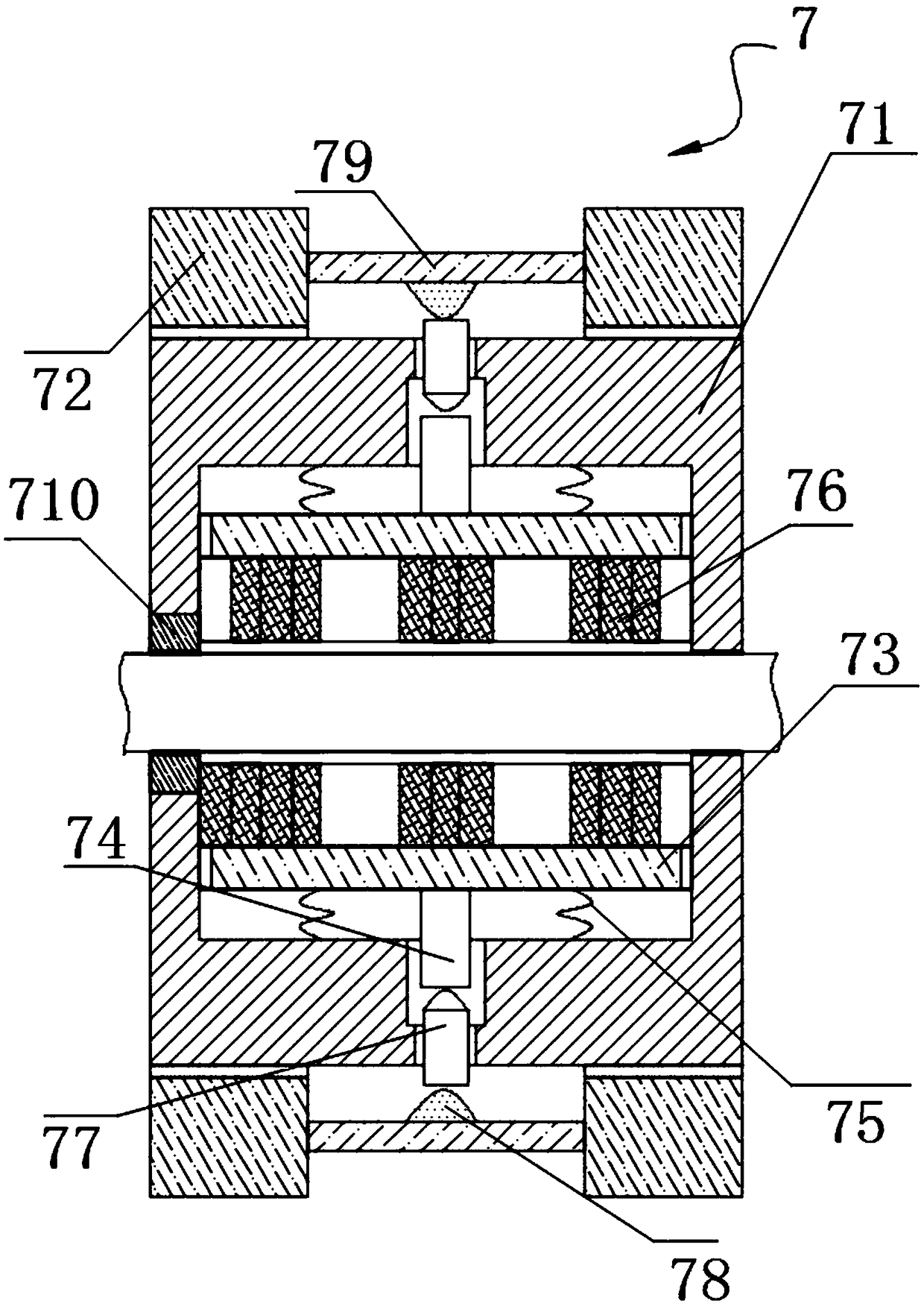

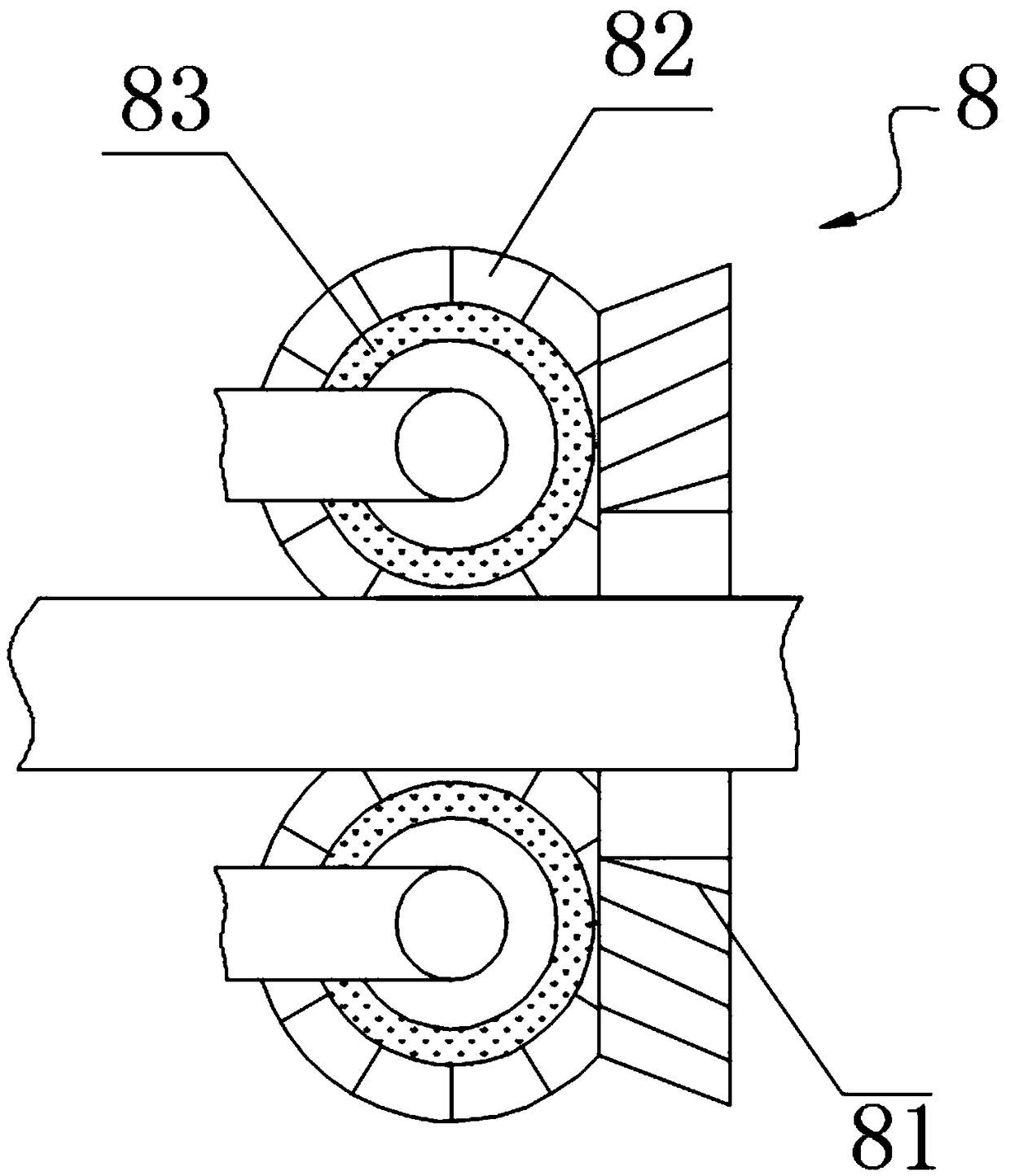

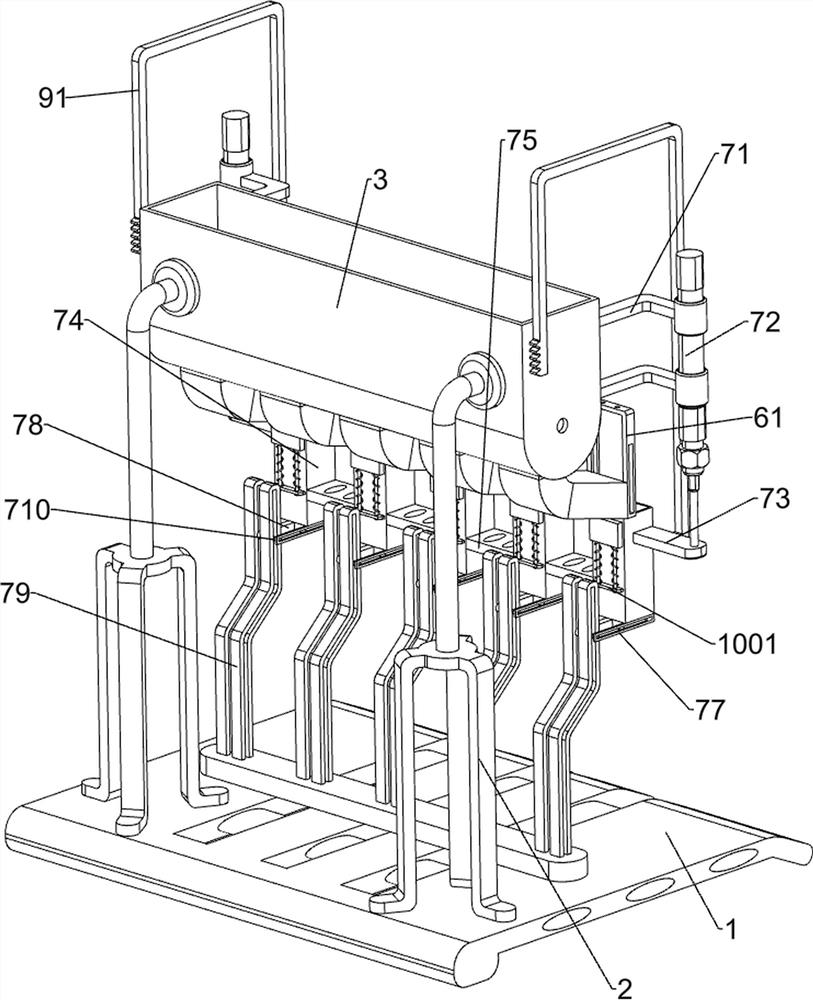

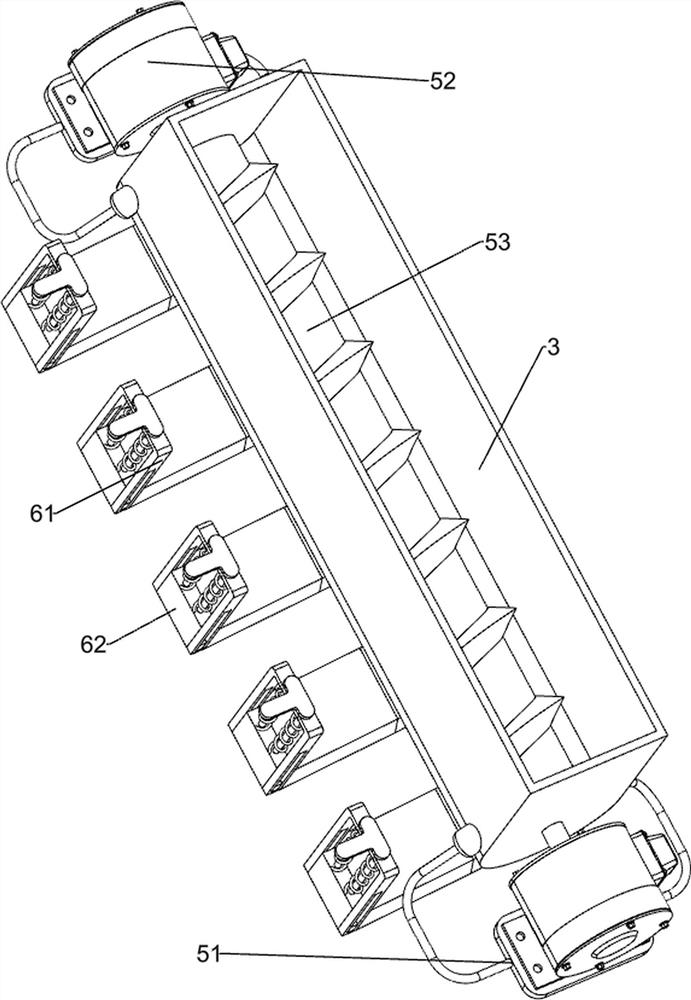

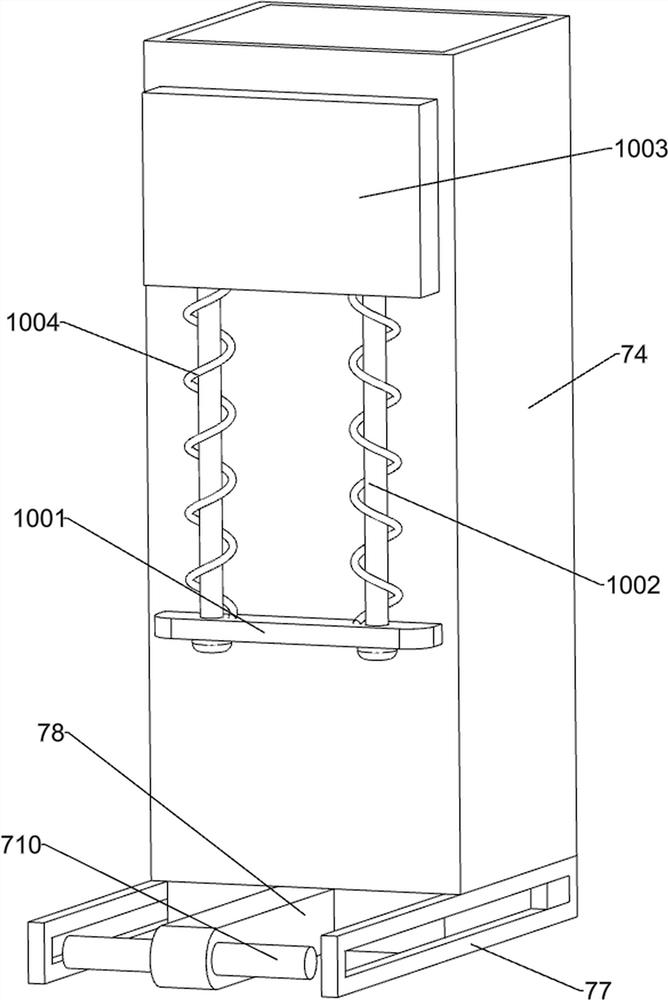

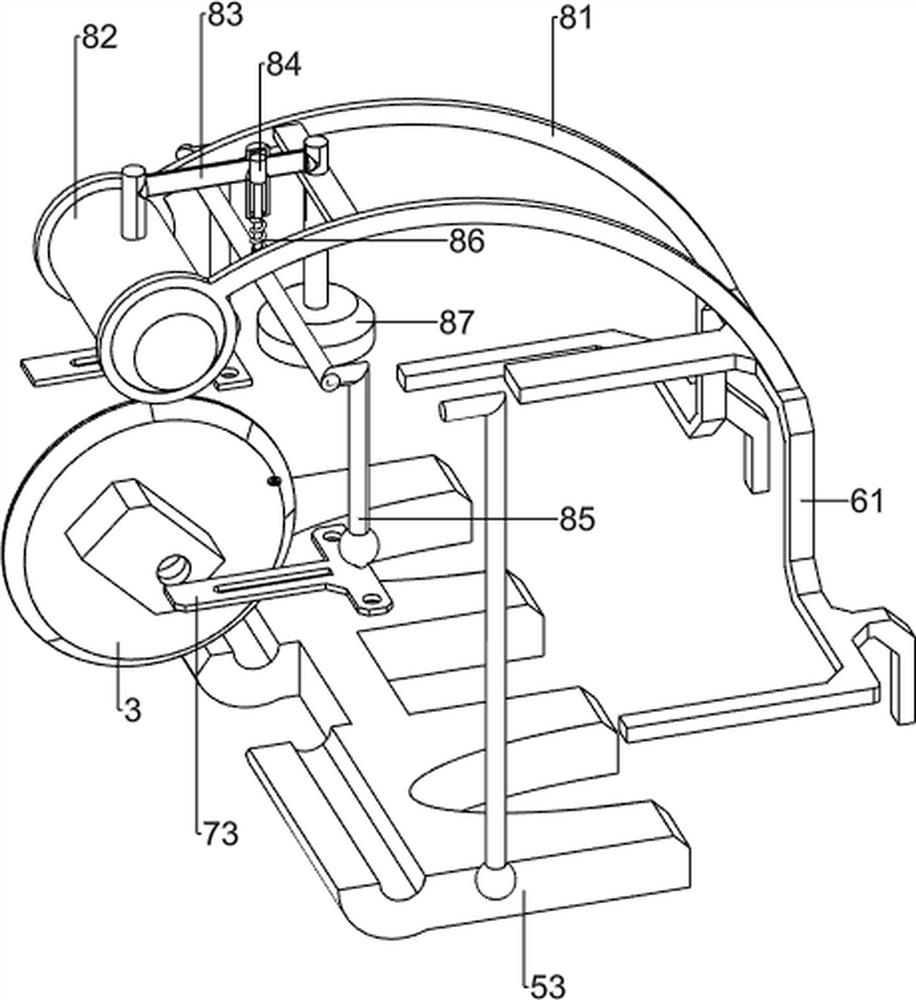

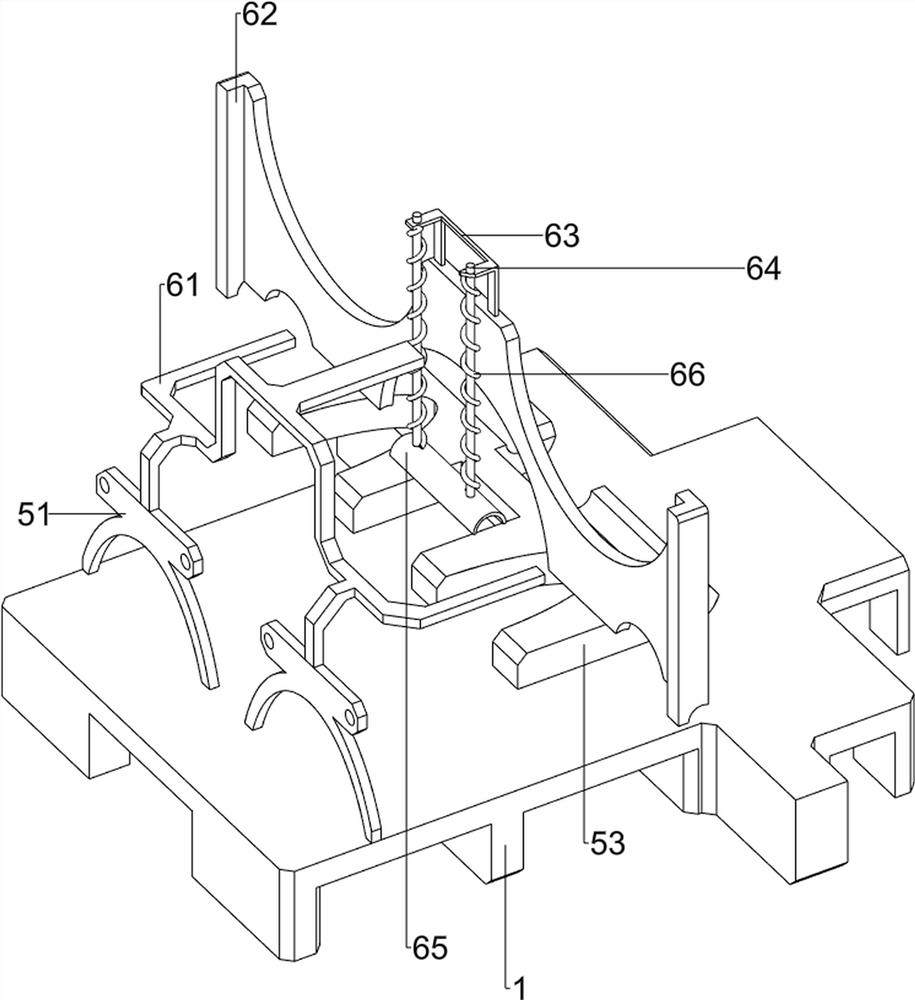

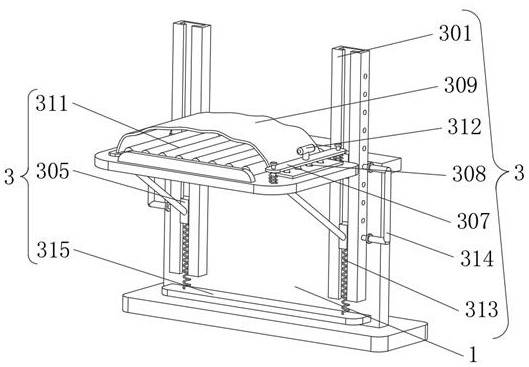

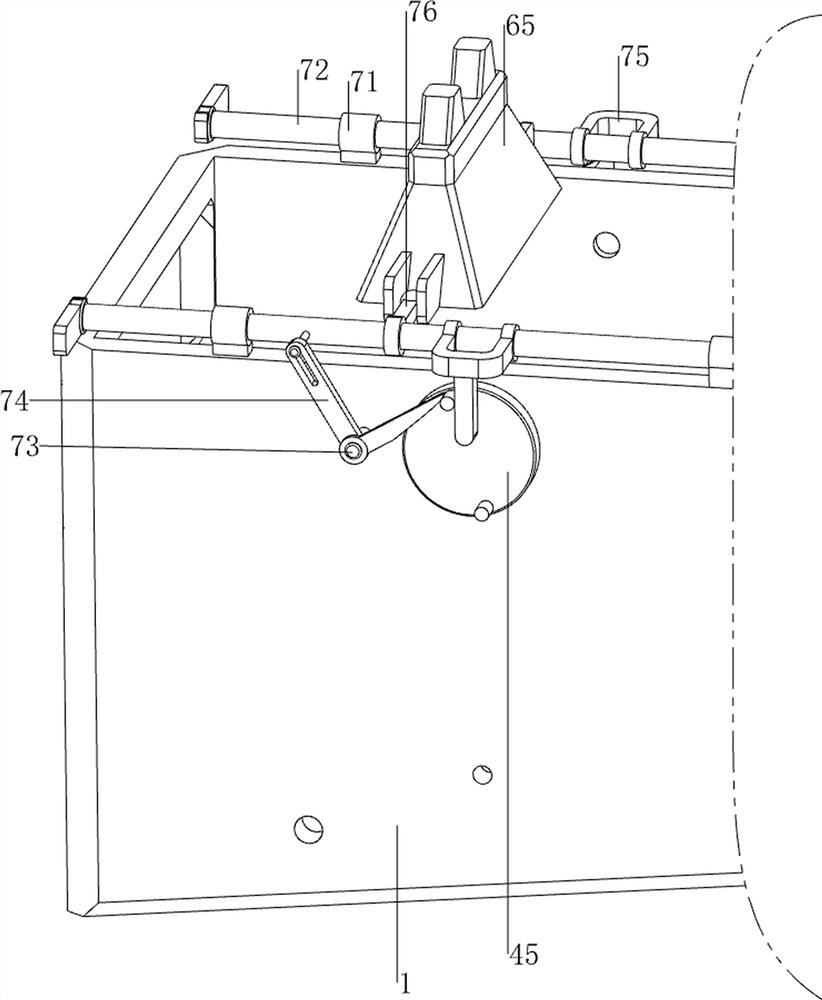

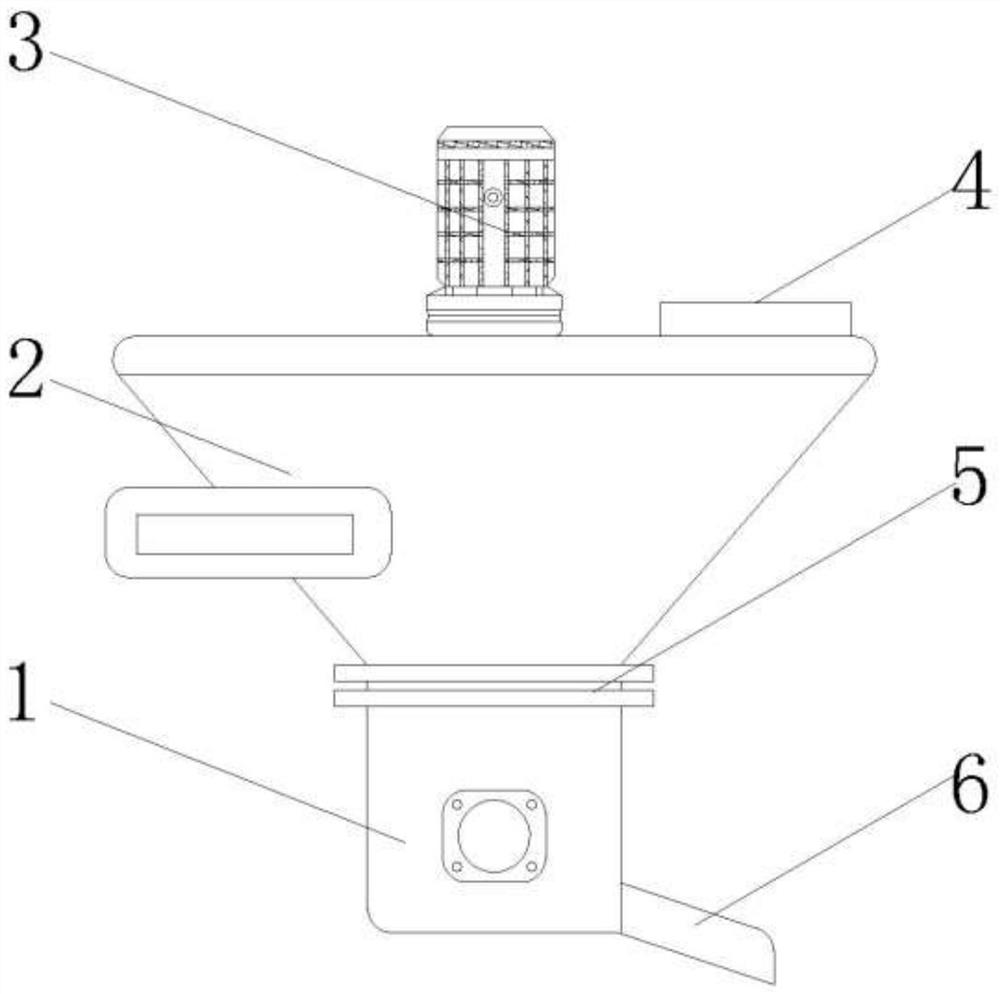

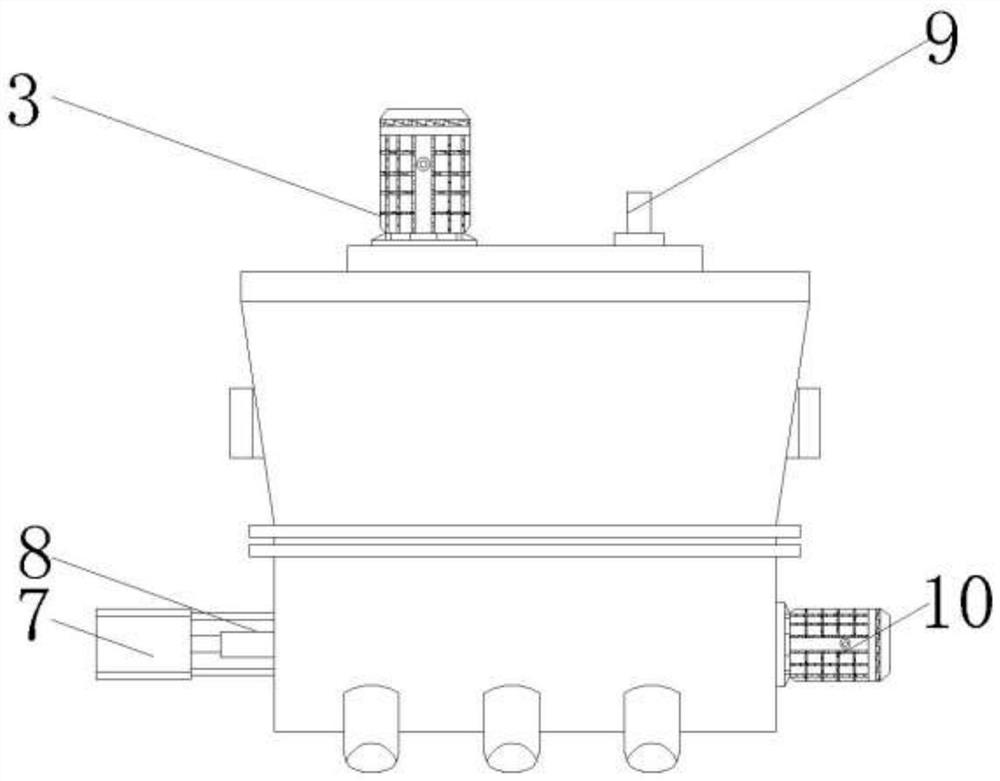

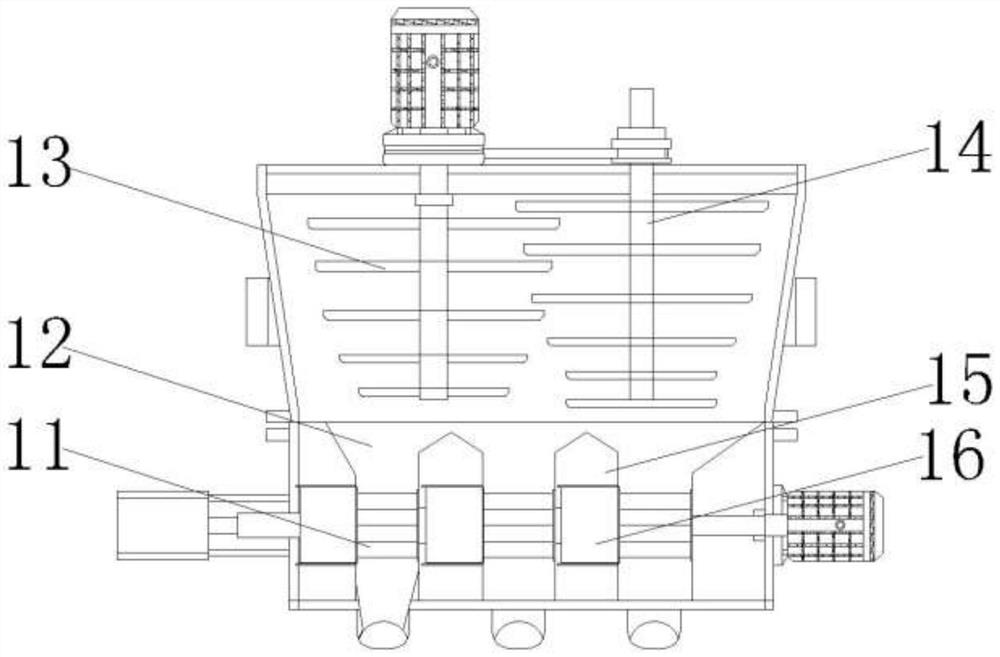

Flowerpot batch soil covering device for potted plants

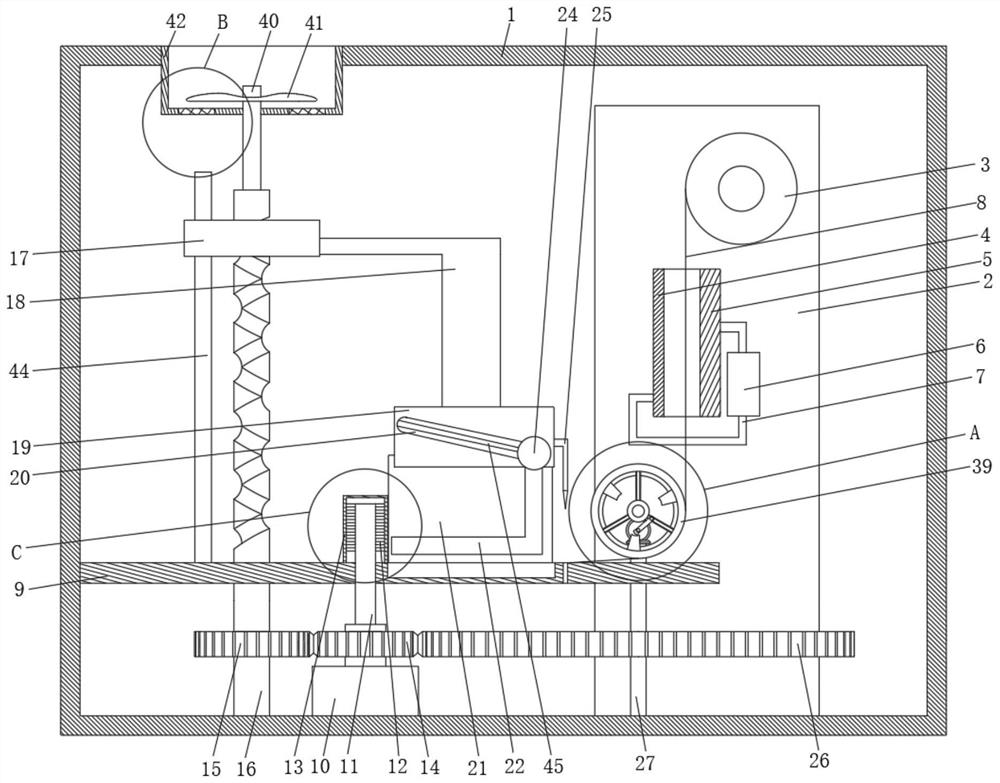

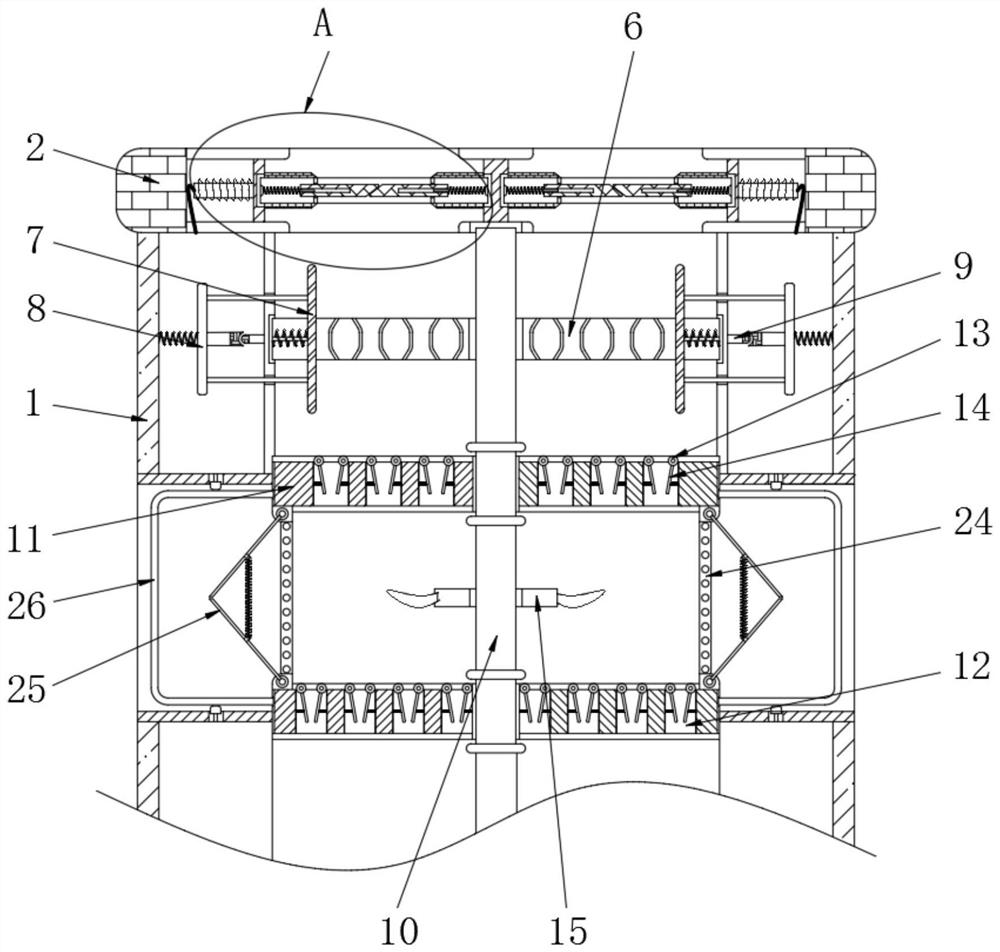

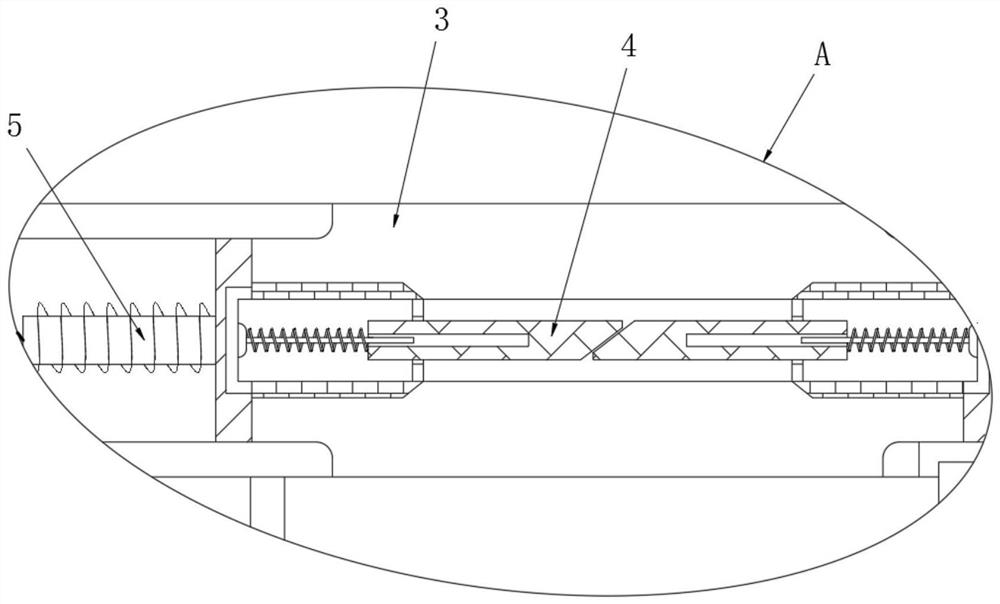

PendingCN112997752ATo achieve the effect of covering soilTo achieve the effect of feedingTransportation and packagingMixersAgricultural engineeringFlowerpot

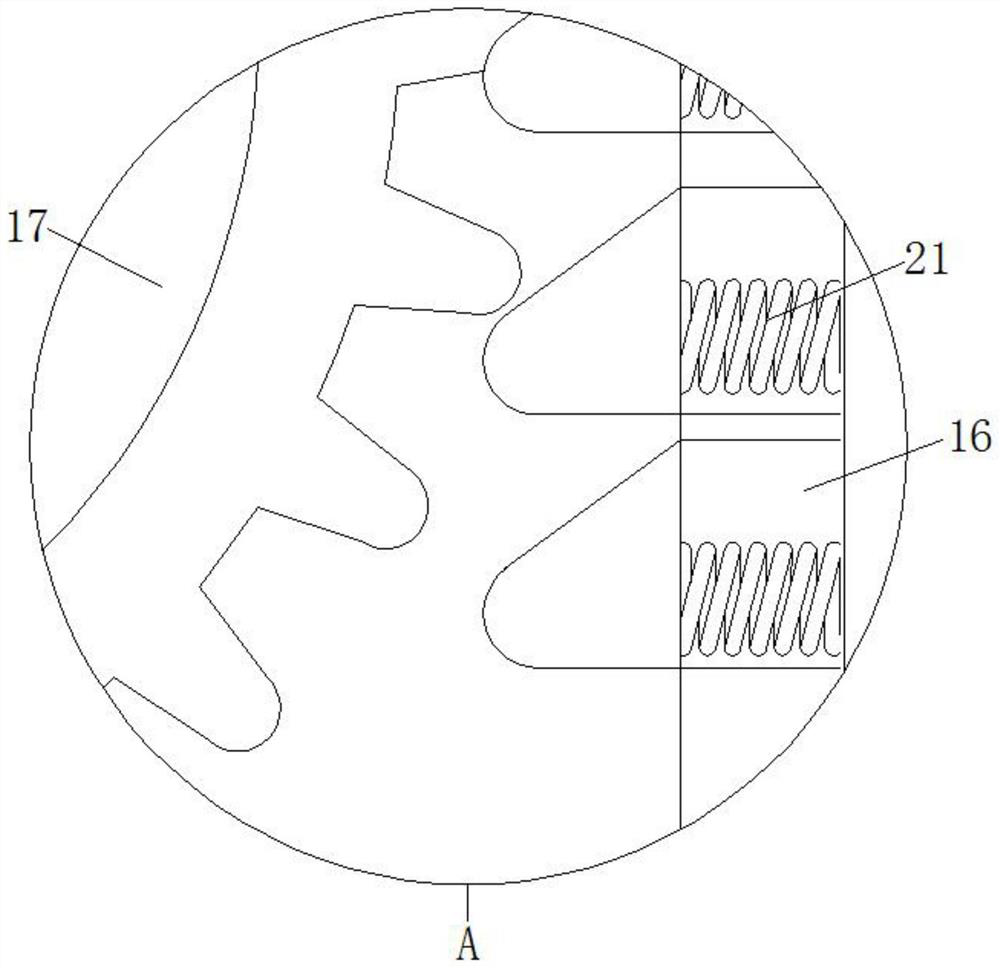

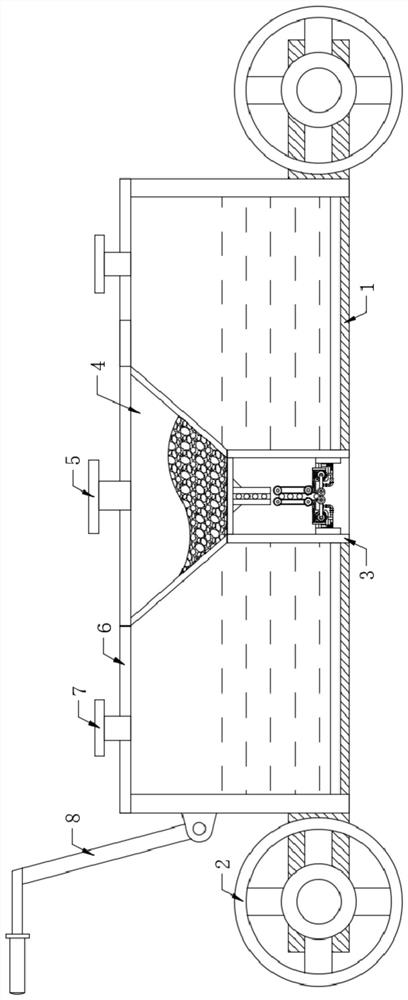

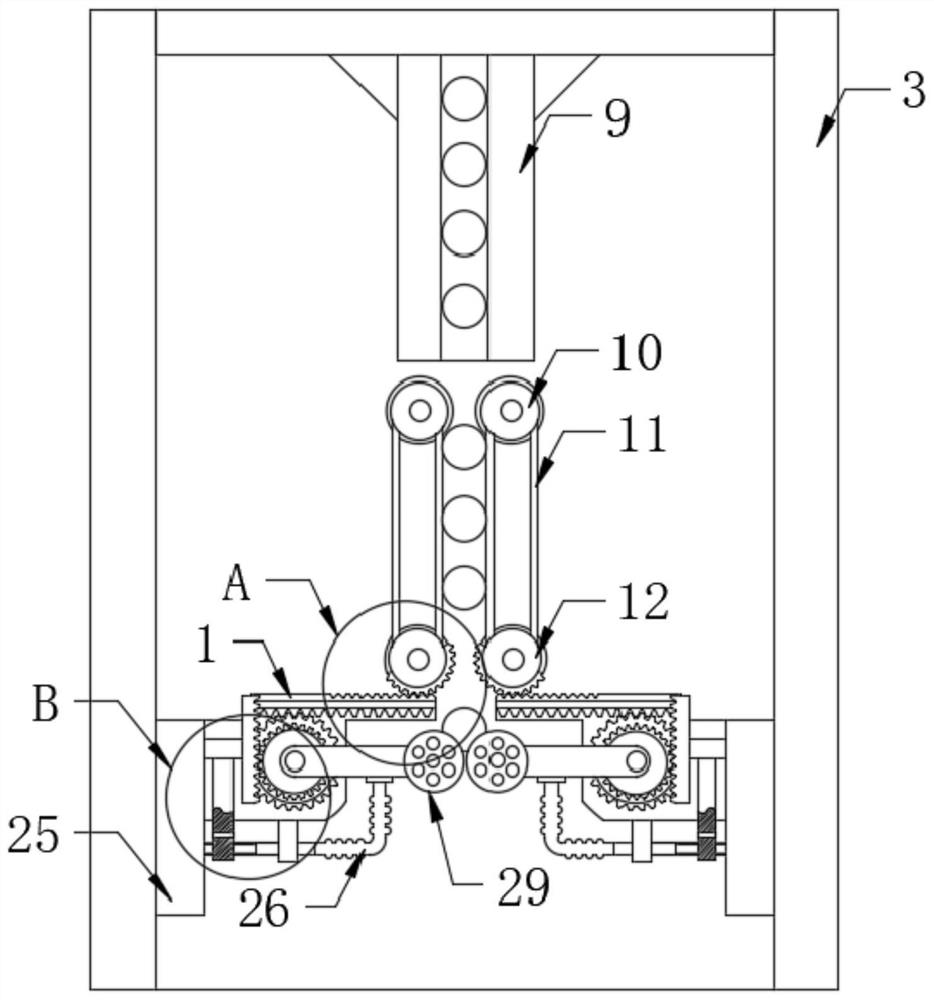

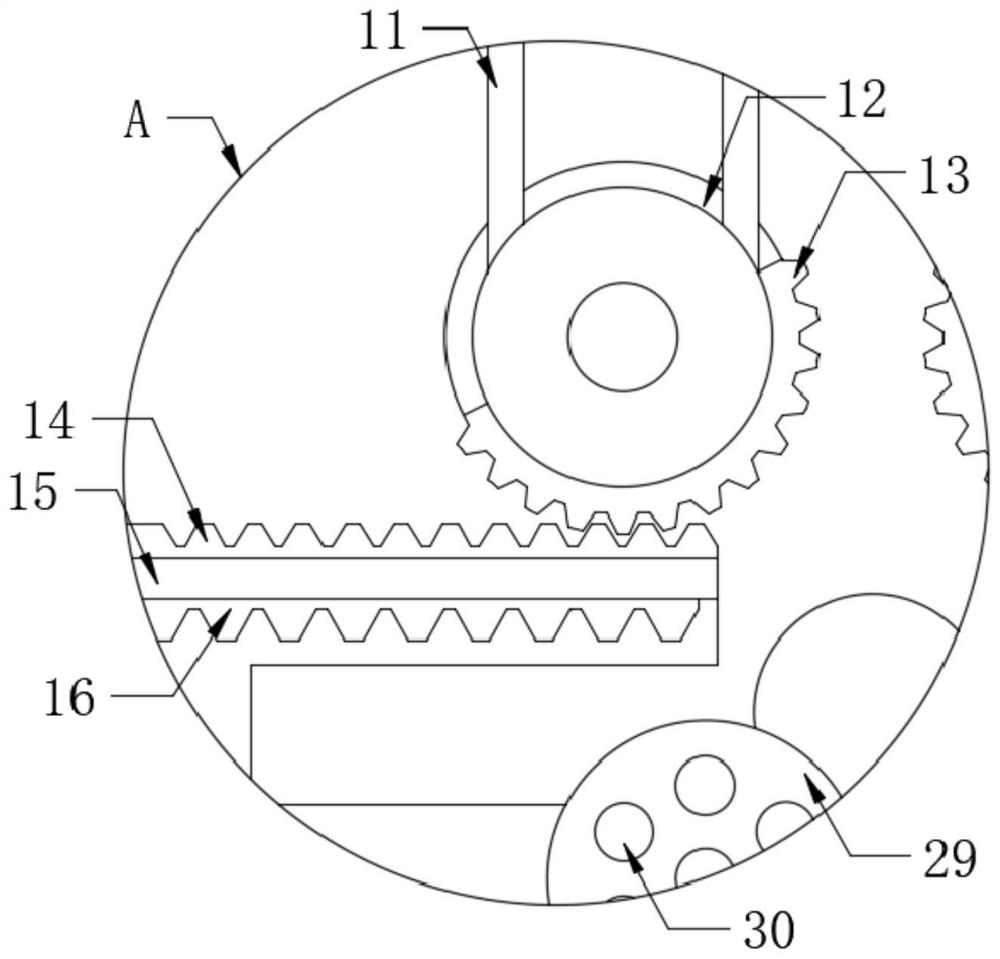

The invention relates to a soil covering device, in particular to a flowerpot batch soil covering device for potted plants. The technical problem to be solved by the invention is how to design the flowerpot batch soil covering device for potted plants, which can cover a plurality of flowerpots with soil at one time, improve the working efficiency and crush soil blocks. In order to solve the technical problem, the flowerpot batch soil covering device for potted plants comprises a bottom frame, wherein first fixing frames are connected to the two sides of the top of the bottom frame; a material containing box which is connected between the two first fixing frames; a supporting frame which is connected to one side of the top of the bottom frame; a crushing mechanism which is arranged on the material containing box; and a material blocking mechanism which is arranged on the material containing box. According to the flowerpot batch soil covering device for the potted plants, the crushing mechanism and the material blocking mechanism cooperate to carry out soil covering on the flowerpots, so that the effect of carrying out soil covering on the flowerpots is achieved.

Owner:涂曦雯

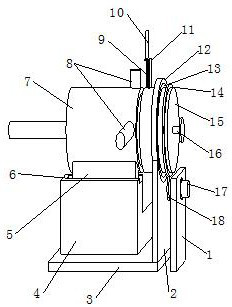

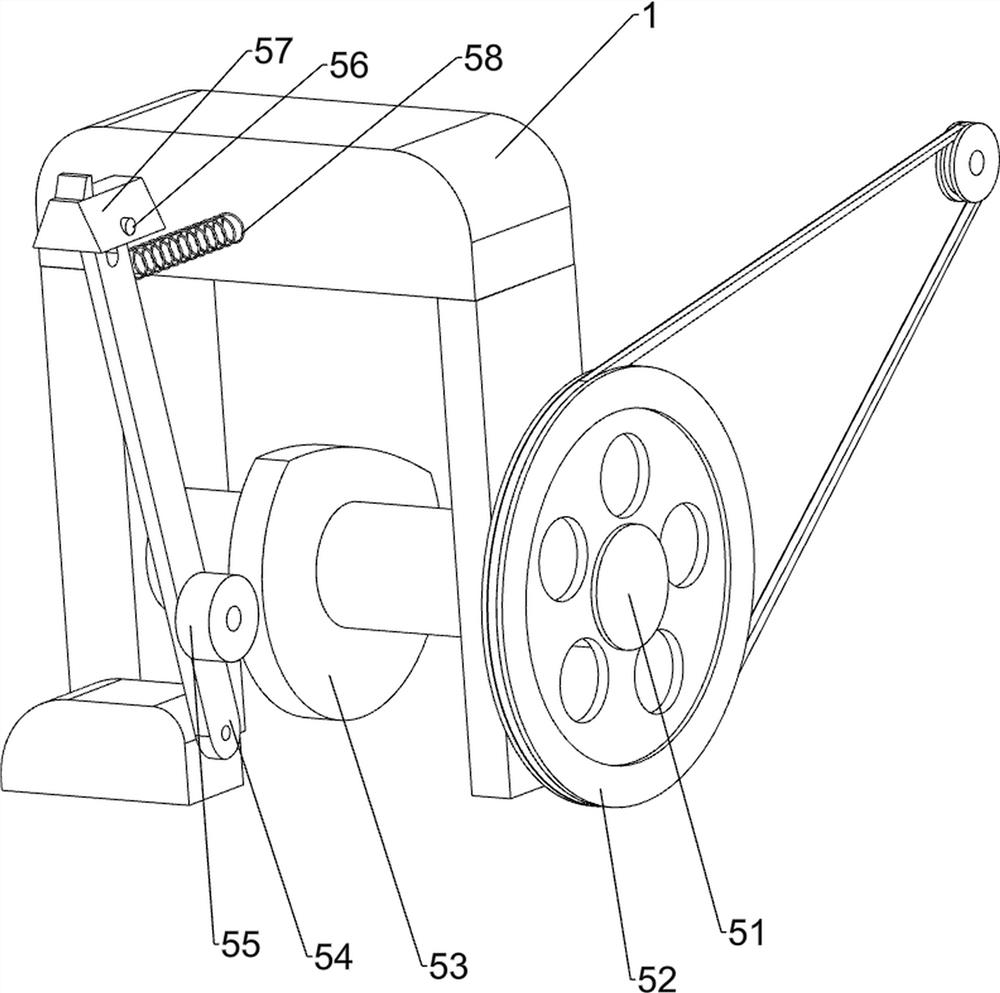

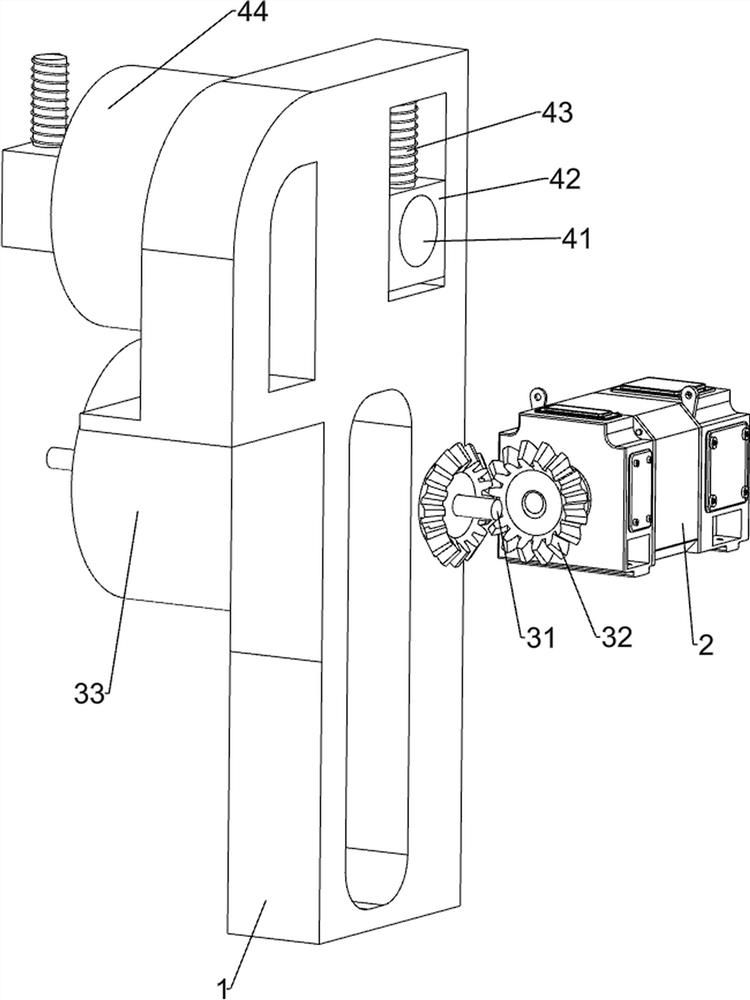

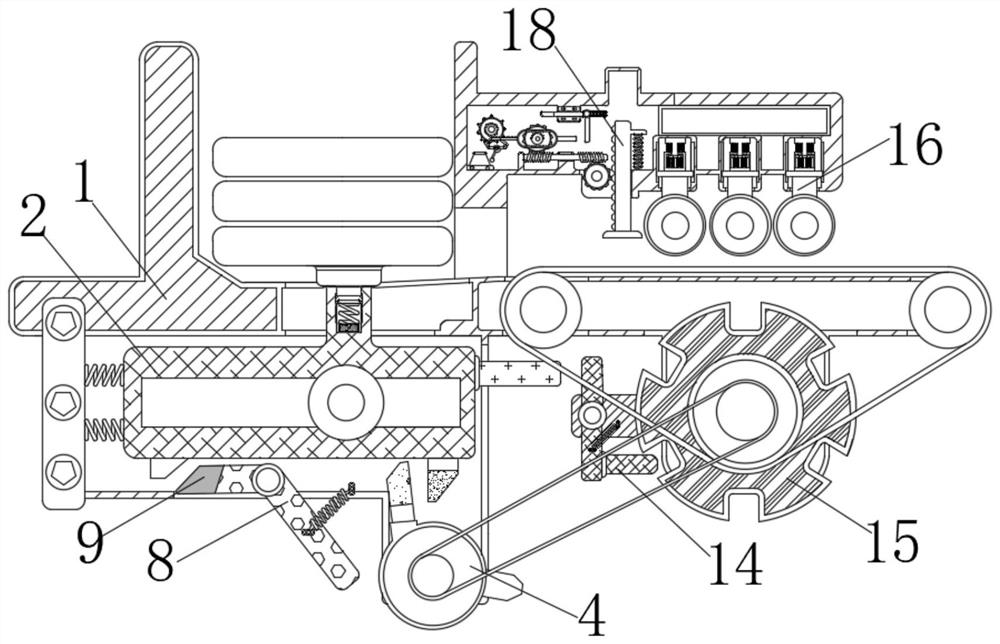

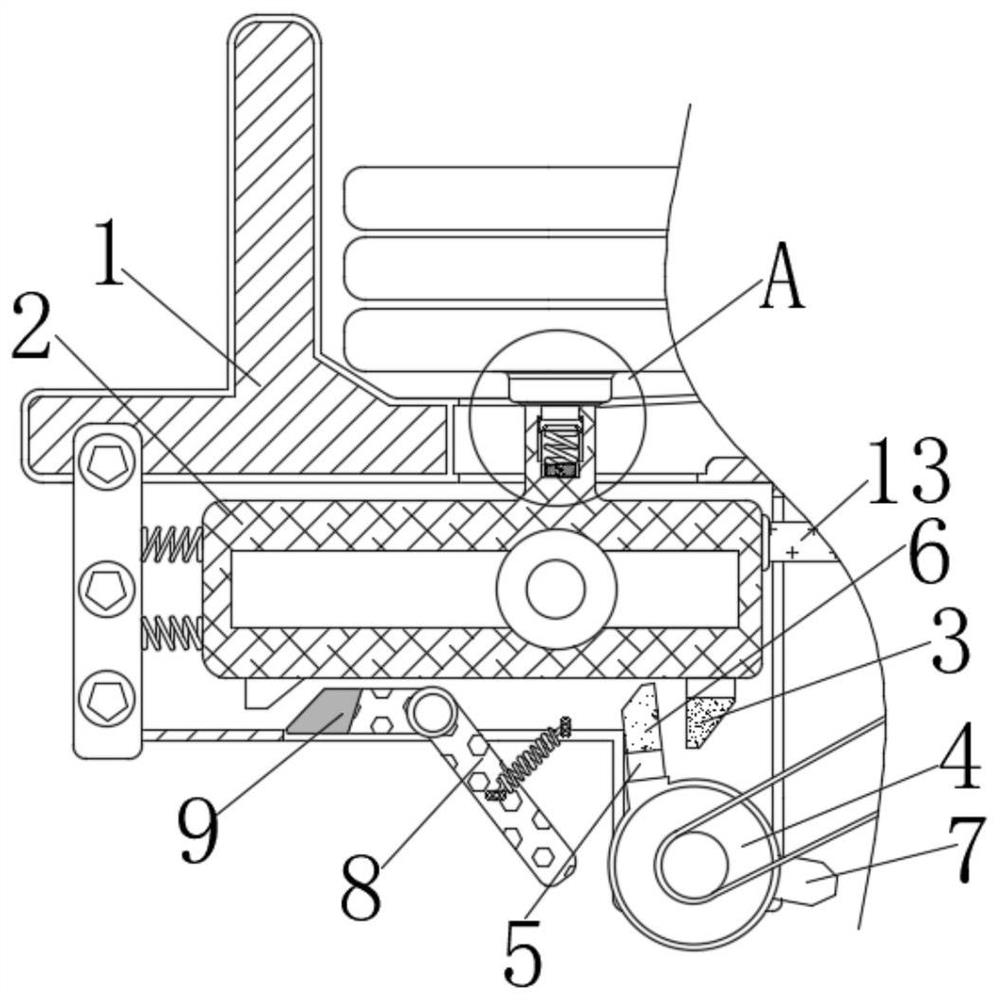

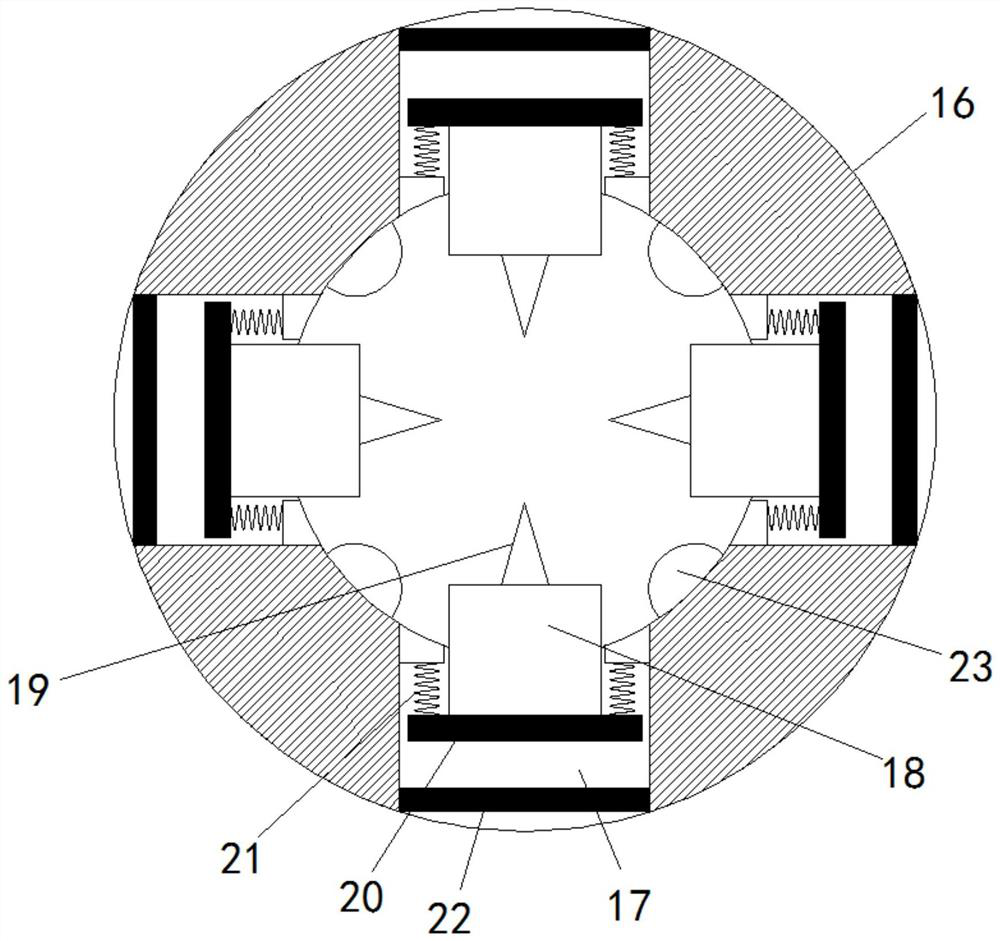

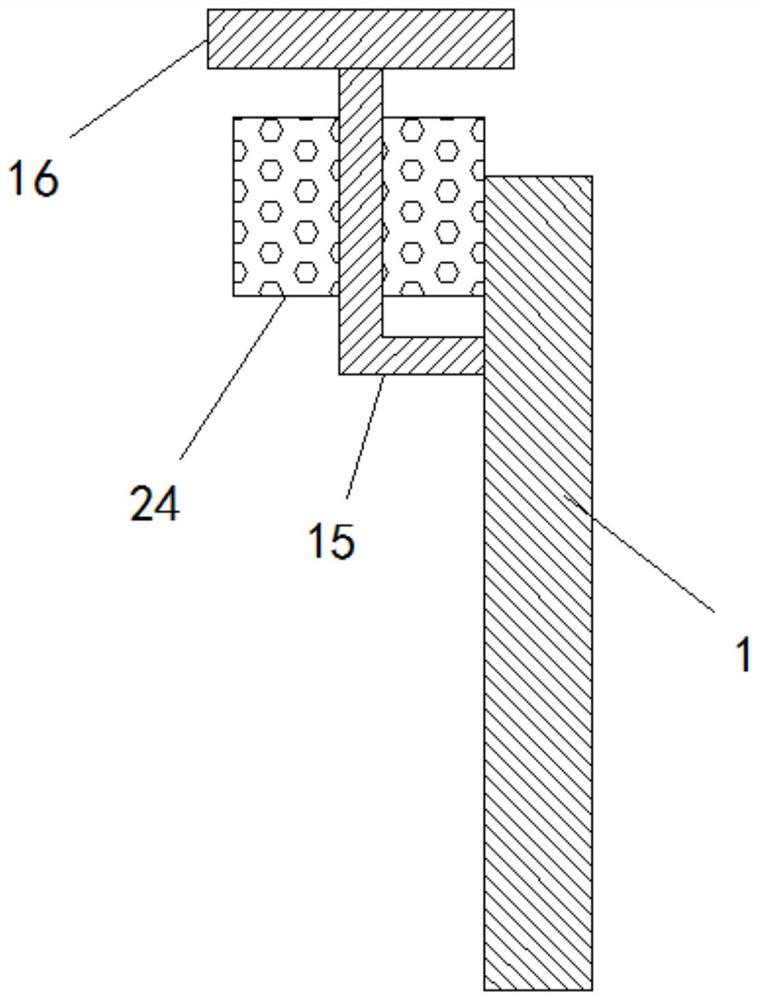

Steel pipe equidistant segmentation equipment for municipal construction

ActiveCN113042805ATo achieve the effect of rotationSave human effortTube shearing machinesMaintainance and safety accessoriesTransmission beltAgricultural engineering

The invention relates to segmentation equipment, in particular to steel pipe equidistant segmentation equipment for municipal construction. The steel pipe equidistant segmentation equipment for municipal construction achieves automatic clamping and automatic cooling and is simple in operation. The steel pipe equidistant segmentation equipment for municipal construction comprises a bottom plate, supports, a rotating mechanism, an electric cutting wheel and a feeding mechanism. The supports are arranged on the two sides of the bottom plate. The rotating mechanism is arranged between the two supports. The electric cutting wheel is arranged on the rotating mechanism. The feeding mechanism is arranged on the bottom plate. An output shaft of a servo motor rotates to drive a transmission belt and a first rotating shaft to rotate, and therefore first connecting blocks are driven to rotate, then the rotating electric cutting wheel drives a second rotating shaft to rotate, the rotating effect is achieved, and manpower is saved; and steel pipes are placed on a carrying plate, then an air cylinder is started, an telescopic rod of the air cylinder drives the carrying plate and sliding columns to move leftwards, and the feeding effect is achieved.

Owner:广东昆大钢管有限公司

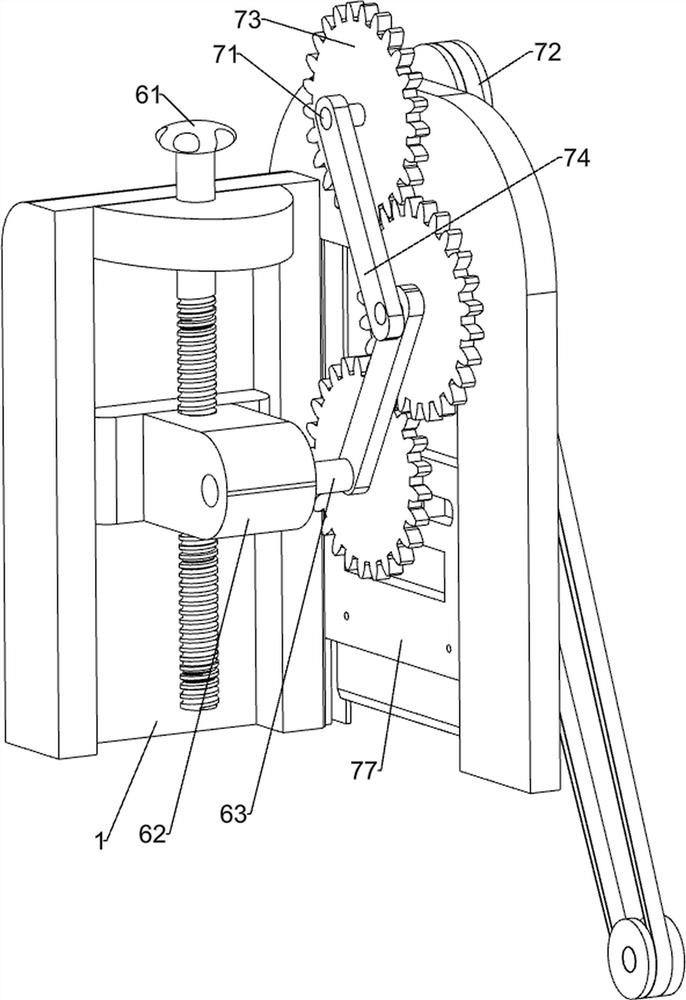

A kind of sapphire wafer cutting equipment and process

ActiveCN110733140BEasy to fixConsistent thicknessSemiconductor/solid-state device manufacturingWorking accessoriesWaferingGear wheel

The invention discloses a sapphire wafer cutting equipment and process, comprising a first support plate, a second support plate, a bottom plate, a U-shaped support plate, a side slide plate, a strip groove, a long cylinder, a first cylinder, a strip cutter, Second cylinder, L-shaped plate, ring frame, bearing, ring gear, short cylinder, screw, servo motor, drive gear, balls, first suction cup, third cylinder, threaded long rod, second suction cup, threaded deep hole and Circular plate. The present invention is convenient to fix the two ends of the sapphire ingot to be cut through two corresponding suction cups and the connecting structure, and at the same time, it can be cut step by step under the push of the third cylinder and the assistance of the ball on the push rod of the first cylinder. The effect of material supply at the structure, by starting the second cylinder to push the connected strip cutter to cut the same part of the sapphire ingot in stages, can avoid the situation of knife jamming, ensure the same cutting amount each time, and avoid cutting out The problem of falling sapphire wafers can be solved, and the yield rate can be improved.

Owner:江苏晶杰光电科技有限公司

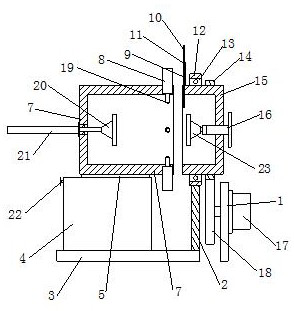

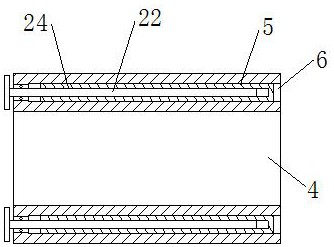

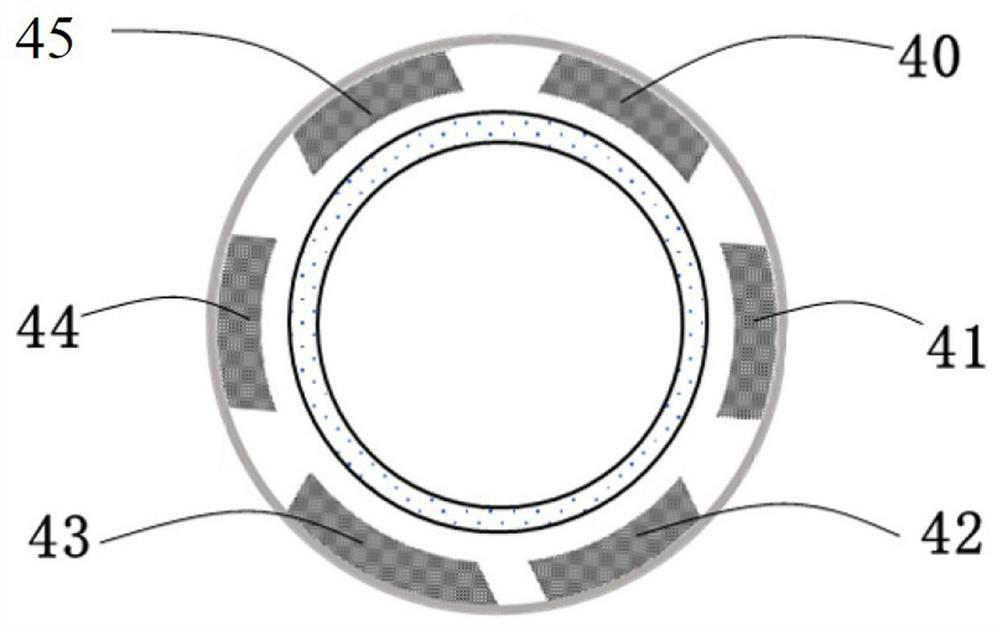

Machining equipment for ultrathin special-shaped copper pipe

ActiveCN113231559AIt has the effect of being fixed on the round rollerPlay a supporting roleMetal-working feeding devicesPositioning devicesStructural engineeringManufacturing engineering

The invention provides machining equipment for an ultrathin special-shaped copper pipe, and relates to the technical field of copper pipe machining equipment. The machining equipment for the ultrathin special-shaped copper pipe comprises a machining table and an adjusting device, a driver is fixedly installed on the surface of the machining table, the adjusting device is arranged on the surface of the machining table, and comprises two sliding rails, the two sliding rails are evenly and fixedly connected to the surface of the machining table, first sliding blocks are slidably connected to the inner walls of the sliding rails, a rectangular plate is fixedly connected to the ends, away from the inner walls of the sliding rails, of the two first sliding blocks, two supporting rods are evenly and fixedly connected to the lower surface of the rectangular plate, the ends, away from the rectangular plate, of the supporting rods are fixedly connected with second sliding blocks, and the ends, away from the supporting rods, of the second sliding blocks are slidably connected with the sliding rails. The problems that an operator places a plurality of machined special-shaped copper pipes in order and then carries the machined special-shaped copper pipes back and forth, time and labor are wasted, and the production efficiency of machining equipment is reduced are solved.

Owner:江西耐乐科技协同创新有限公司 +2

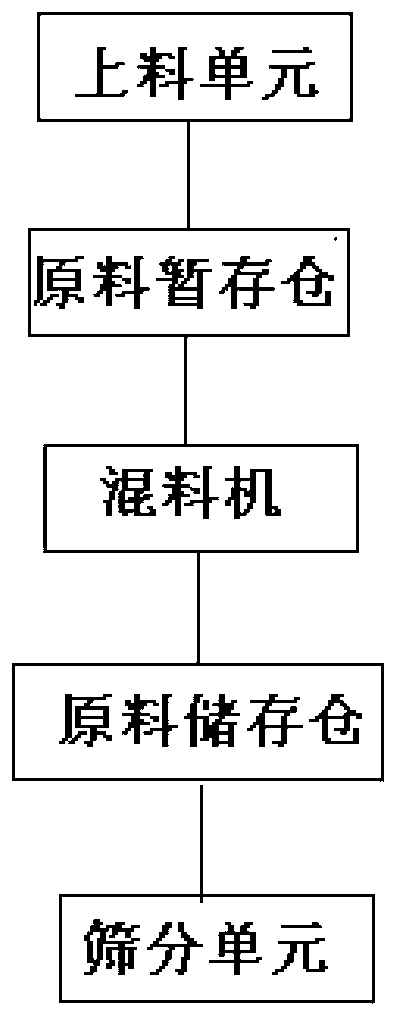

Automatic mixing and screening device for silicon carbide micropowder

InactiveCN103274415AReduce delivery pressureReliable deliverySilicon carbideSize compositionRaw material

The invention discloses an automatic mixing and screening device for silicon carbide micropowder, which comprises a charging unit, a temporary raw material storage bin, a mixer, a raw material storage bin and a screening unit, wherein the charging unit is used for conveying the silicon carbide micropowder to the temporary raw material storage bin; the temporary raw material storage bin is used for temporarily storing the silicon carbide micropowder conveyed by the charging unit, and conveying the silicon carbide micropowder to the mixer; the mixer is used for mixing and stirring the received silicon carbide micropowder, and then conveying the silicon carbide micropowder to the raw material storage bin; the raw material storage bin is used for storing the silicon carbide micropowder discharged by the mixer, and conveying the silicon carbide micropowder to the screening unit; and the screening unit is used for performing screening treatment on the received silicon carbide micropowder. The automatic mixing and screening device for the silicon carbide micropowder can automatically perform charging, mixing and screening, can effectively improve the size composition of the silicon carbide micropowder, and meets a grain requirement of photovoltaic edge material cutting.

Owner:佳明新材料科技有限公司

Wood board uniform cutting equipment for building materials

InactiveCN112265074ATo achieve the effect of backward transmissionRealize the effect of squeezing and fixingProfiling/shaping machinesArchitectural engineeringMechanical engineering

The invention relates to uniform cutting equipment, in particular to wood board uniform cutting equipment for building materials. The wood board uniform cutting equipment for the building materials reduces the labor intensity of people, improves the cutting efficiency of wood boards, and is uniform in cutting. The wood board uniform cutting equipment for the building materials comprises a mountingboard, a conveying mechanism, an extrusion mechanism and an adjusting mechanism. A servo motor is mounted on the mounting board. The conveying mechanism is arranged on the side, close to the servo motor, of the mounting board, and the conveying mechanism is connected with the servo motor. The extrusion mechanism is arranged at the position, located above the conveying mechanism, of mounting board. The adjusting mechanism is arranged on the side, close to the extrusion mechanism, of the mounting board. An output shaft of the servo motor rotates to drive a first rotating shaft to rotate, and therefore the first rotating shaft is driven to rotate, then a first rolling wheel is driven to rotate, and the effect of conveying boards passing through the upper portion of the first rolling wheel backwards is achieved.

Owner:谈备

Sewage filtration and disinfection treatment device

PendingCN113880295ATo push the effectAchieve stirring effectSpecific water treatment objectivesTreatment involving filtrationFiltrationSewage

The invention relates to a treatment device, and in particular, relates to a sewage filtration and disinfection treatment device. The invention provides the sewage filtration and disinfection treatment device having the advantages of automatic material pushing, filtration acceleration and automatic material discharging. The sewage filtration and disinfection treatment device comprises a box body, supporting frames, discharging plates, a filter screen, a pushing mechanism, a rotating mechanism and a feeding mechanism; the supporting frames are arranged on the two sides of the box body; the discharging plates are arranged on the two sides of the box body; the filter screen is arranged on the upper side in the box body; the pushing mechanism is arranged in the box body; the rotating mechanism is arranged between the two sides of the box body; and the feeding mechanism is connected between the two sides of the box body. A shifting plate is driven to move forwards, and then a telescopic rod and a first spring are adaptively deformed, so that a scraping plate drives impurities to move forwards into the discharging plate on the front side, and the material pushing effect is achieved.

Owner:周春娟

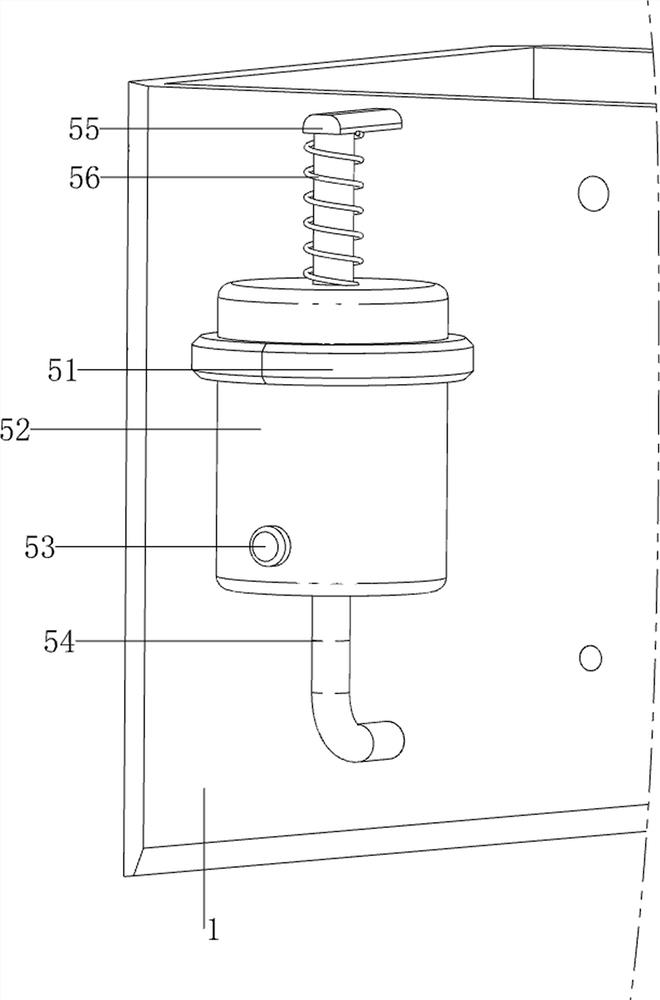

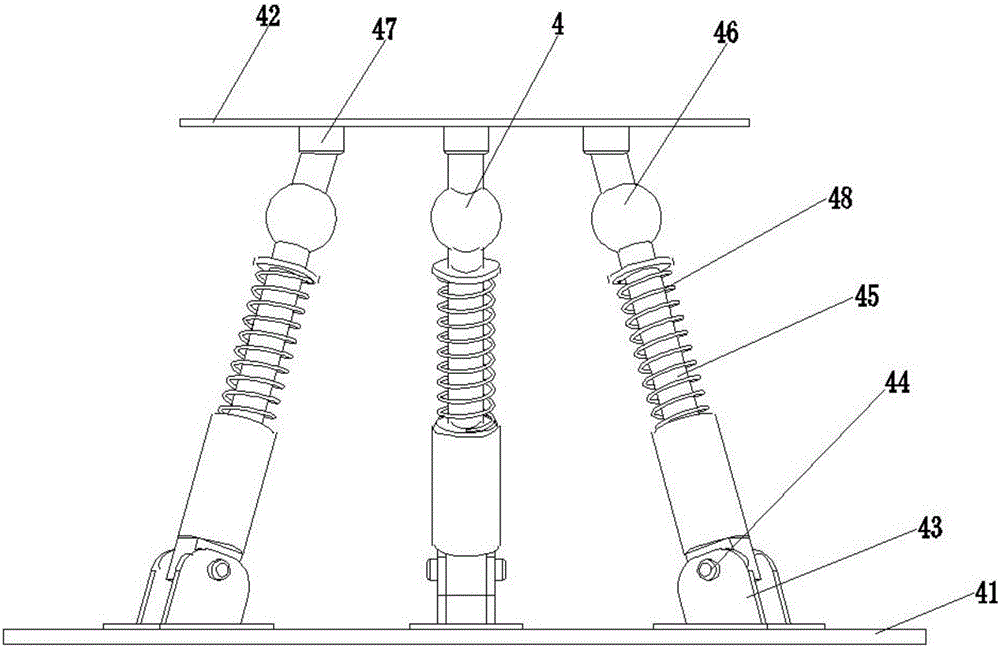

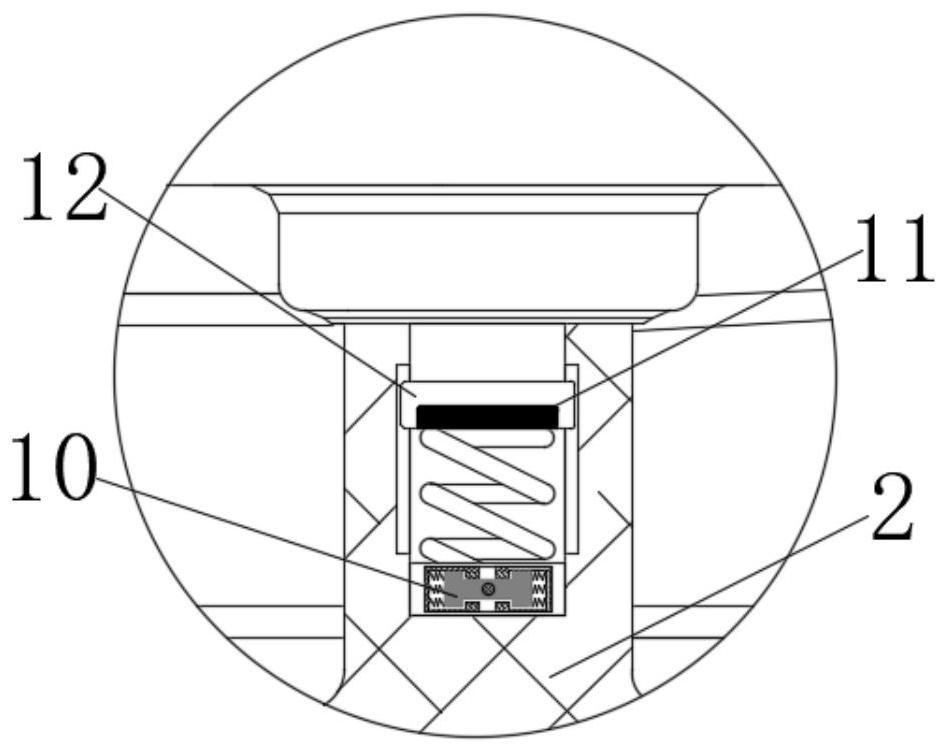

Executing mechanical arm used for complete intelligent fishpond feeding all-in-one machine

InactiveCN106035180ARealize the function of chargingTo achieve the effect of shrinking the wire ropeClimate change adaptationPisciculture and aquariaThree degrees of freedomEngineering

The invention relates to an executing mechanical arm used for a complete intelligent fishpond feeding all-in-one machine. The executing mechanical arm includes a three-degree-of-freedom parallel mechanism and a feeding device. The three-degree-of-freedom parallel mechanism is disposed exactly below the feeding device and the upper end of the three-degree-of-freedom parallel mechanism is connected with the feeding device. The executing mechanical arm has functions of direction and angle adjustment and feed loading and delivery, so that a function of automatic feeding in fishery breeding is realized. Besides, the executing mechanical arm is high in intelligent degree, flexible and convenient for direction and angle adjustment, high in feeding speed and long in feeding distance, and problems of large working load, large risks, low efficiency and the like of prior manual feeding realized by workers riding boats are solved.

Owner:东营尚牧农业科技有限公司

A Vacuum Induction Melting Casting Process and Ingot Mold Device for gh4151 Alloy

Owner:UNIV OF SCI & TECH BEIJING

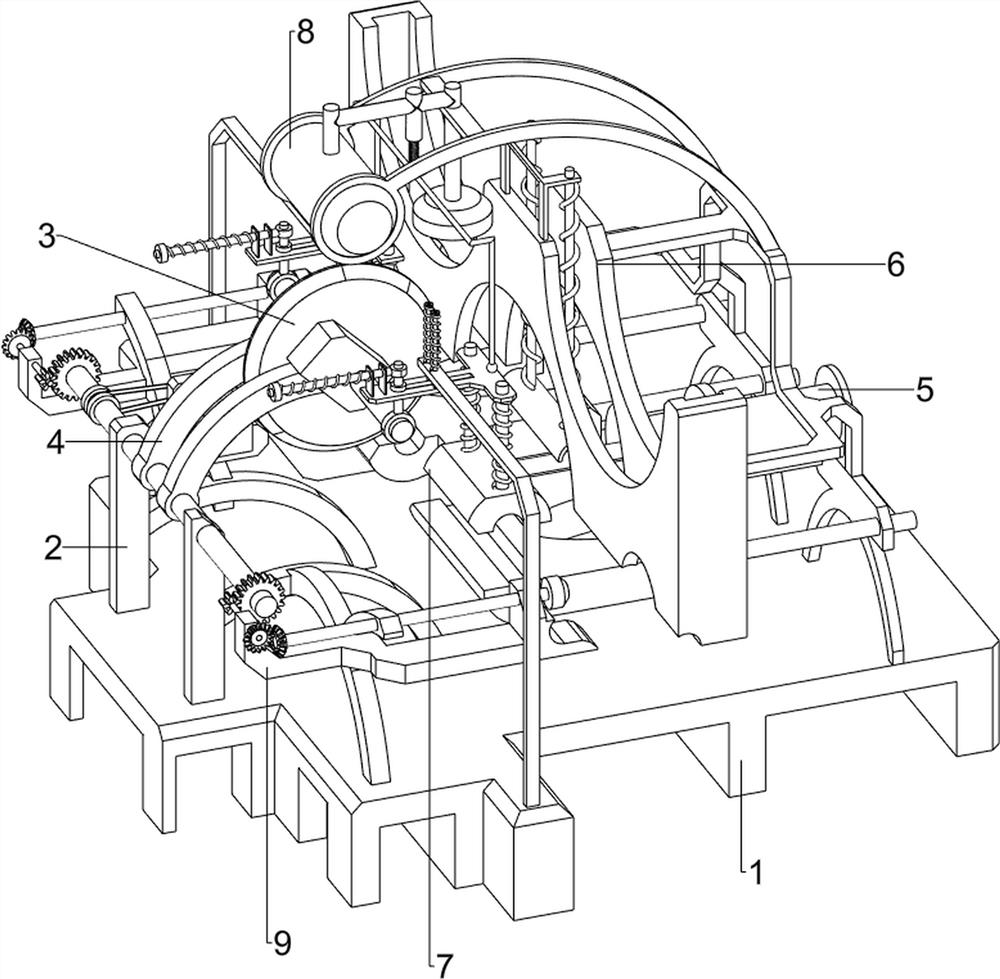

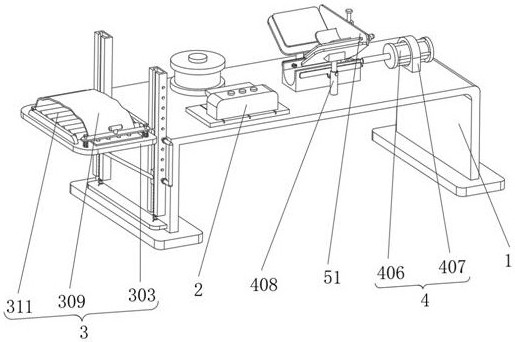

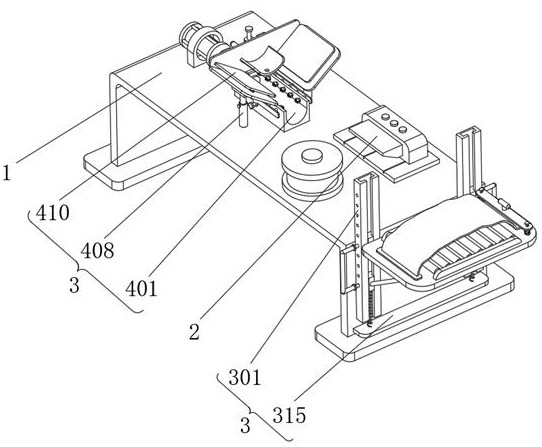

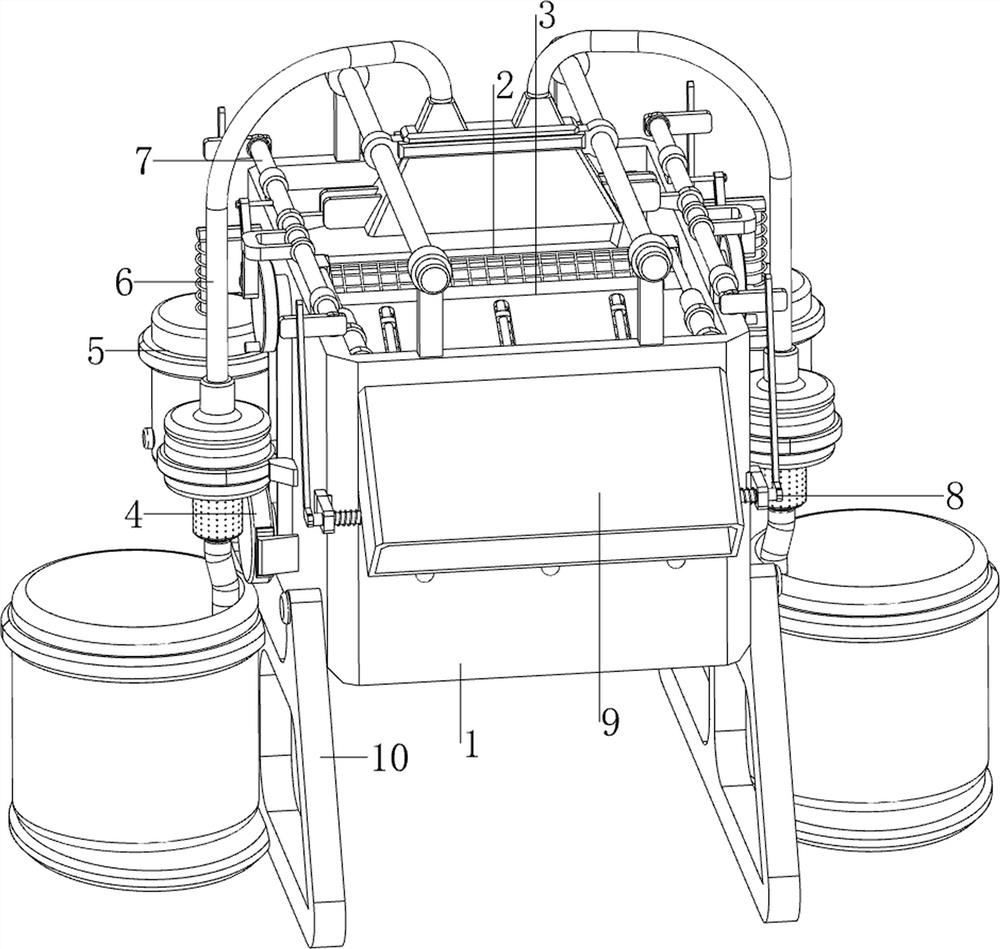

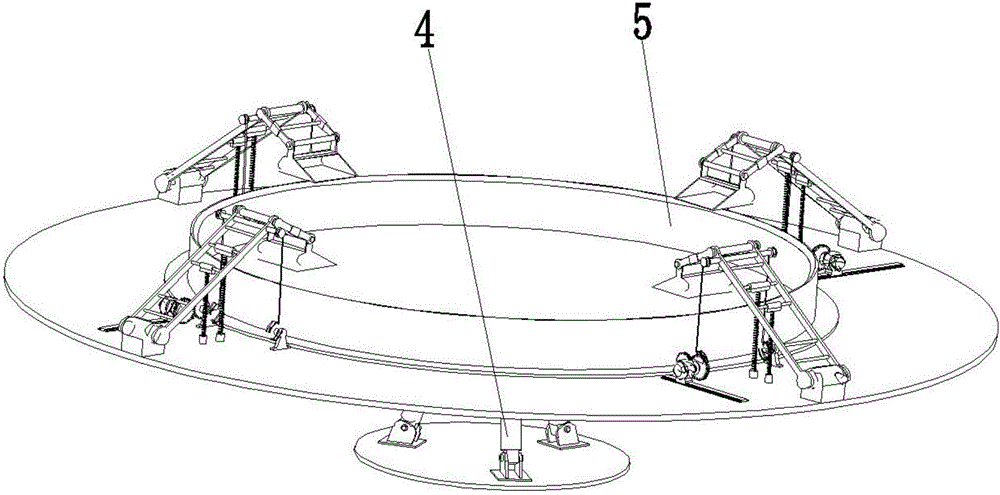

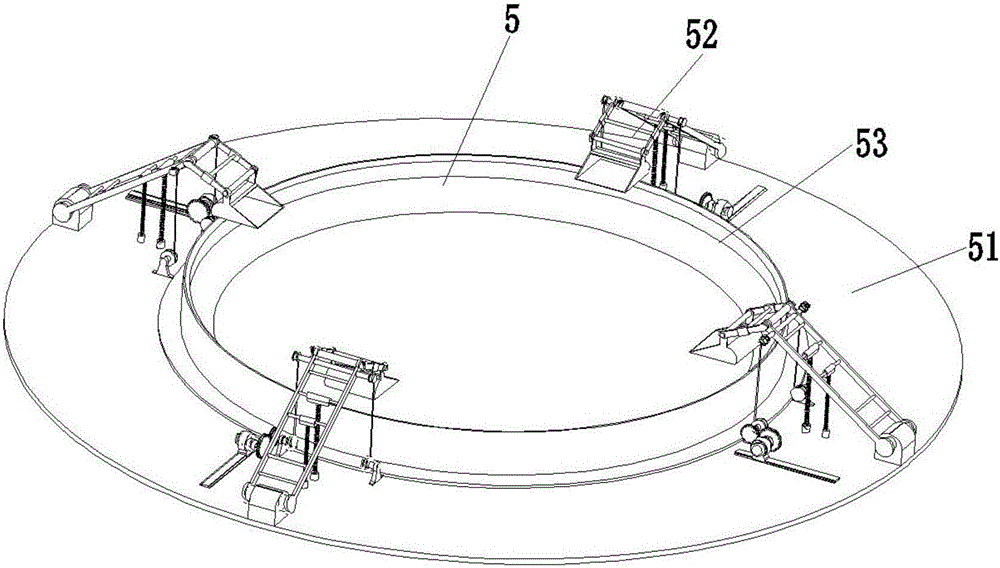

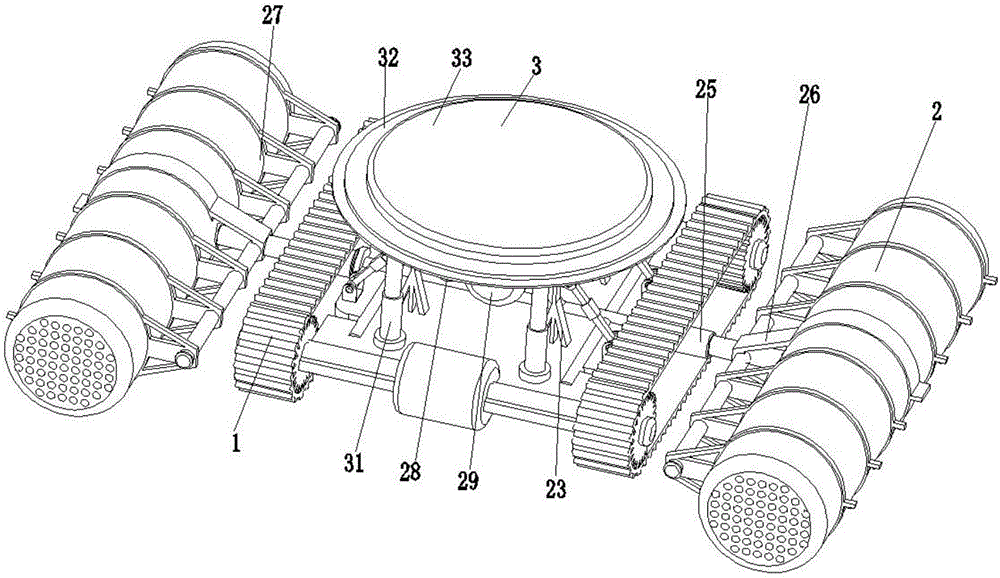

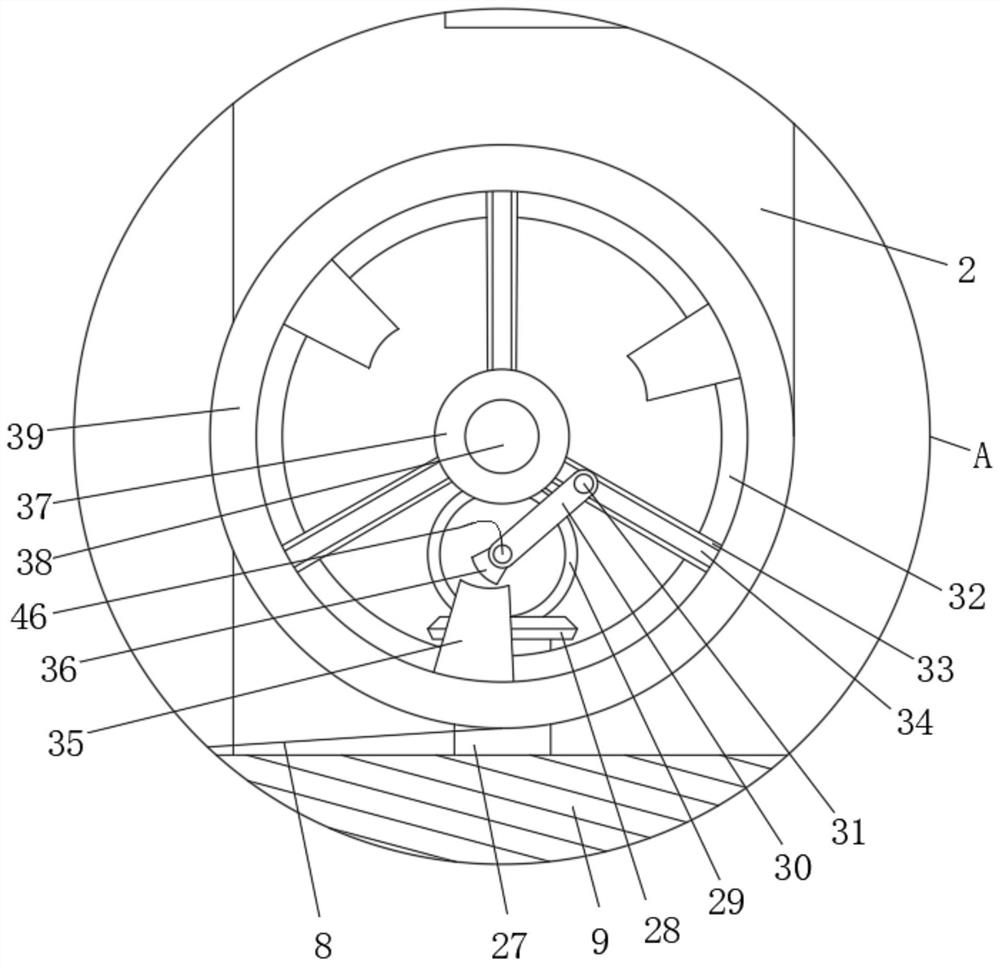

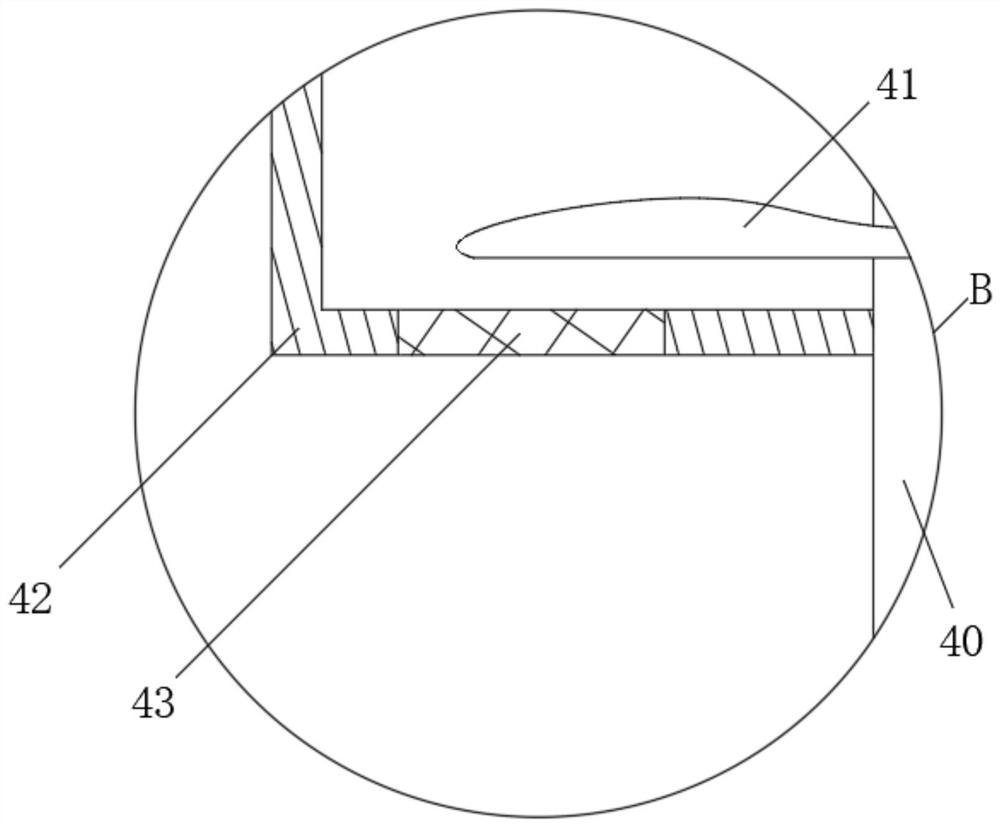

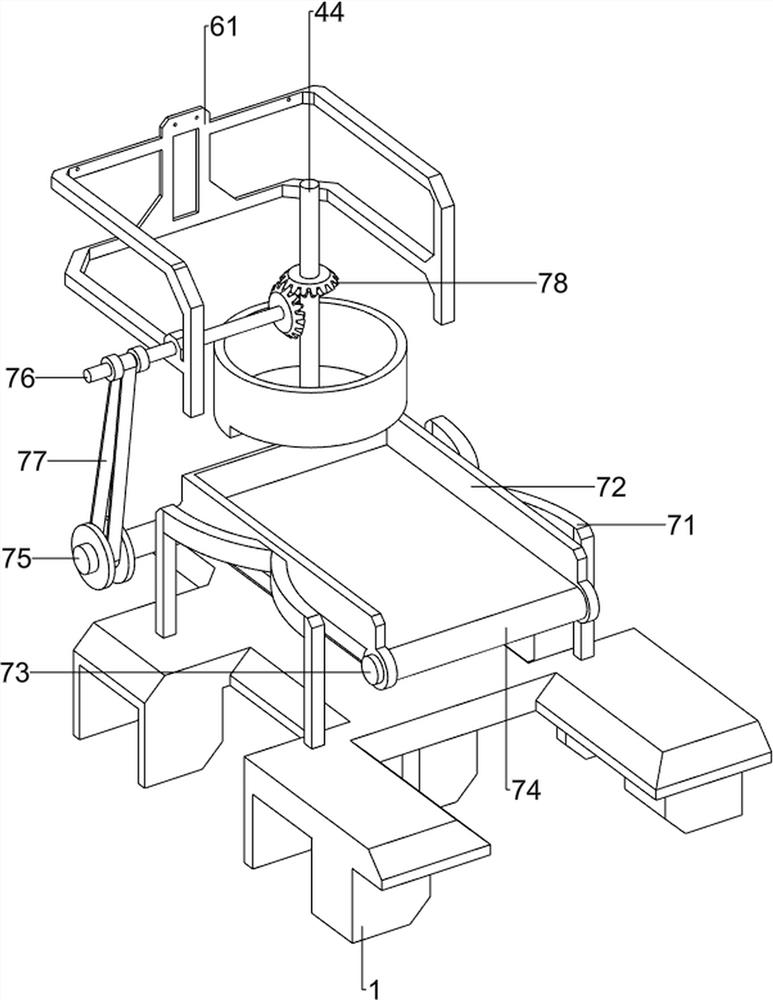

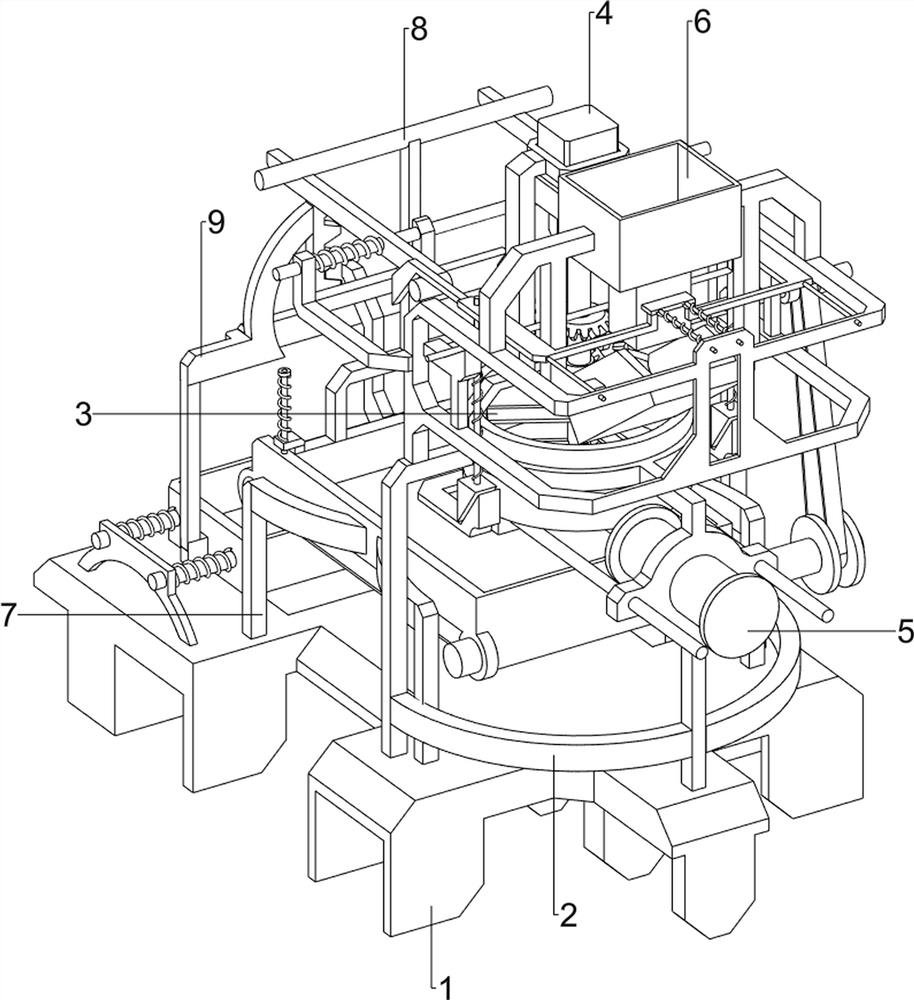

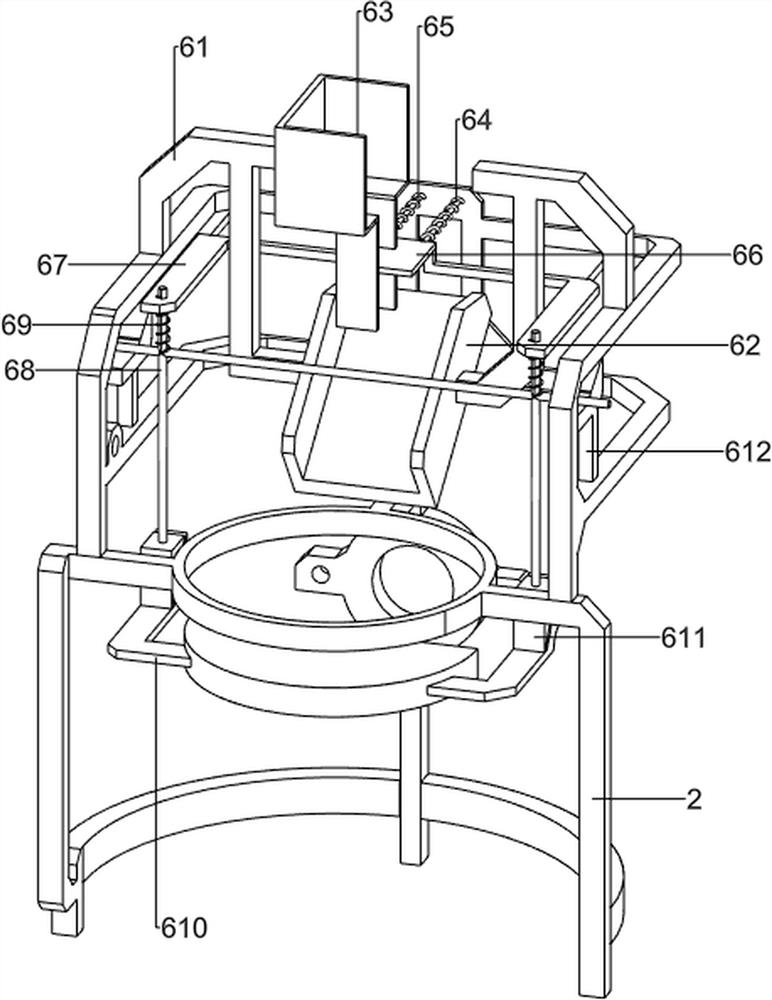

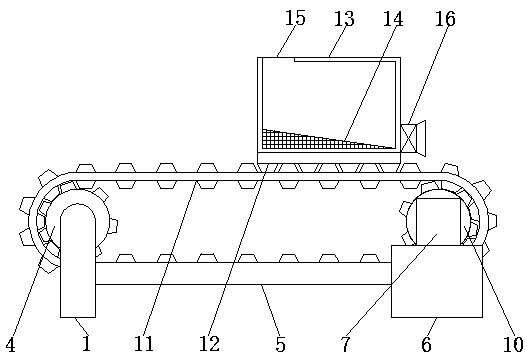

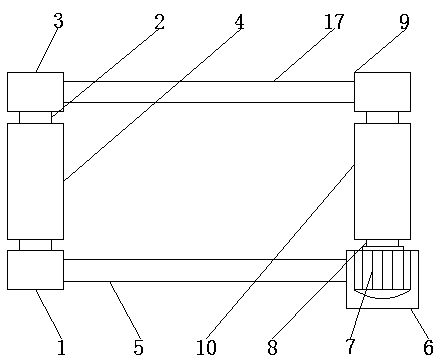

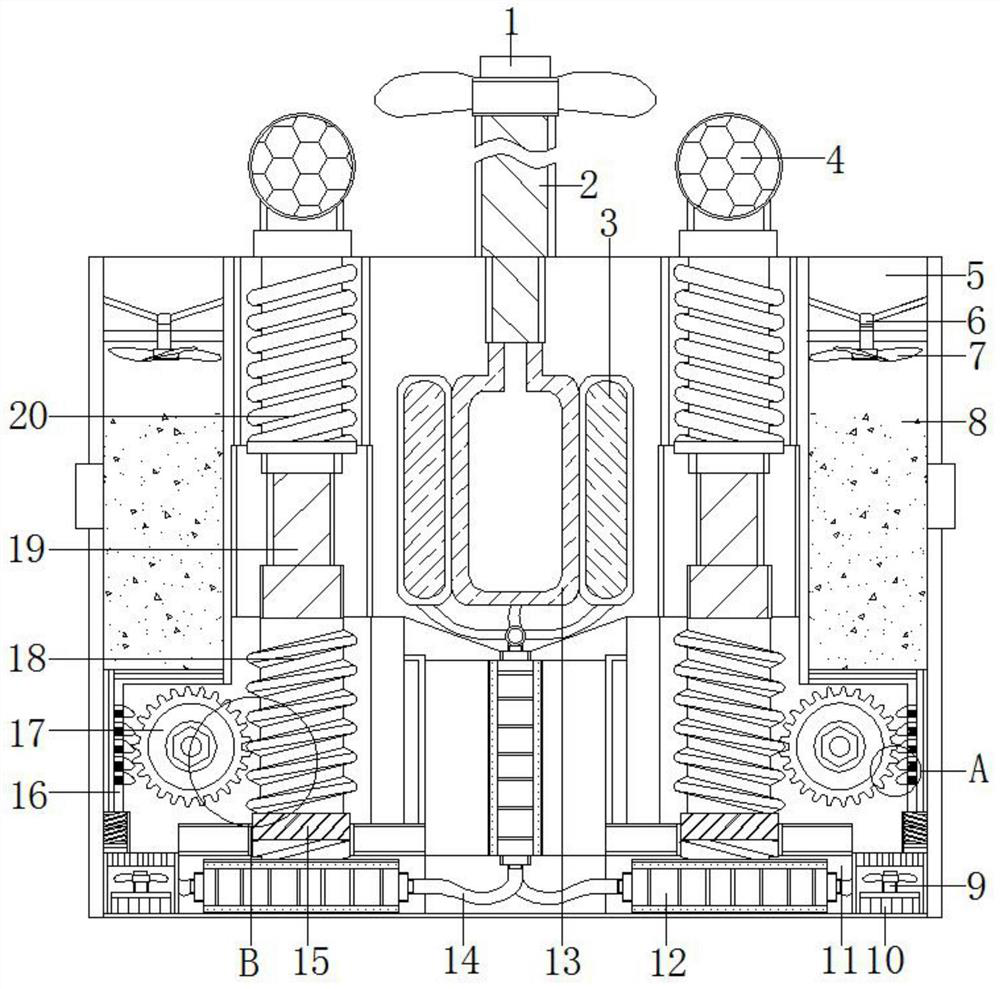

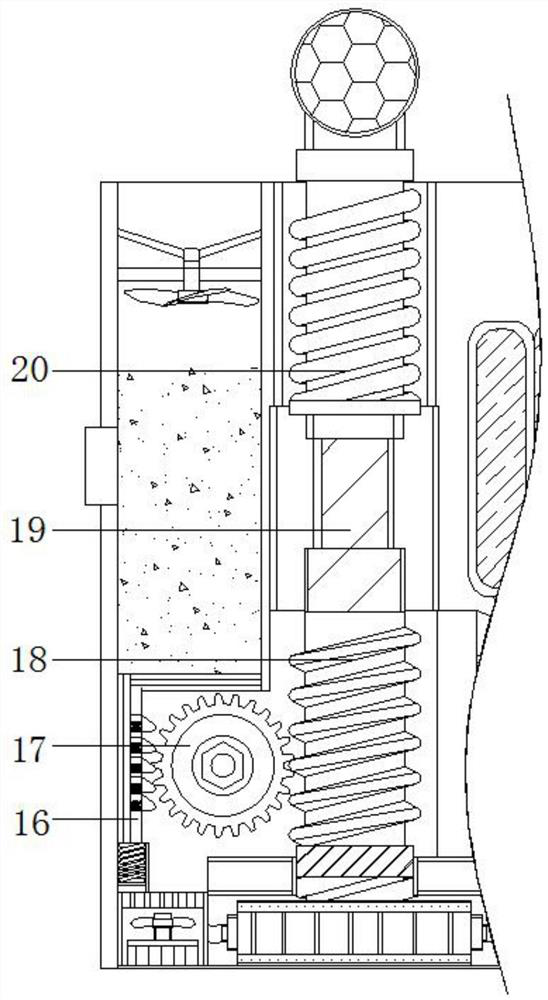

Full-intelligent fishpond feed putting integrated machine

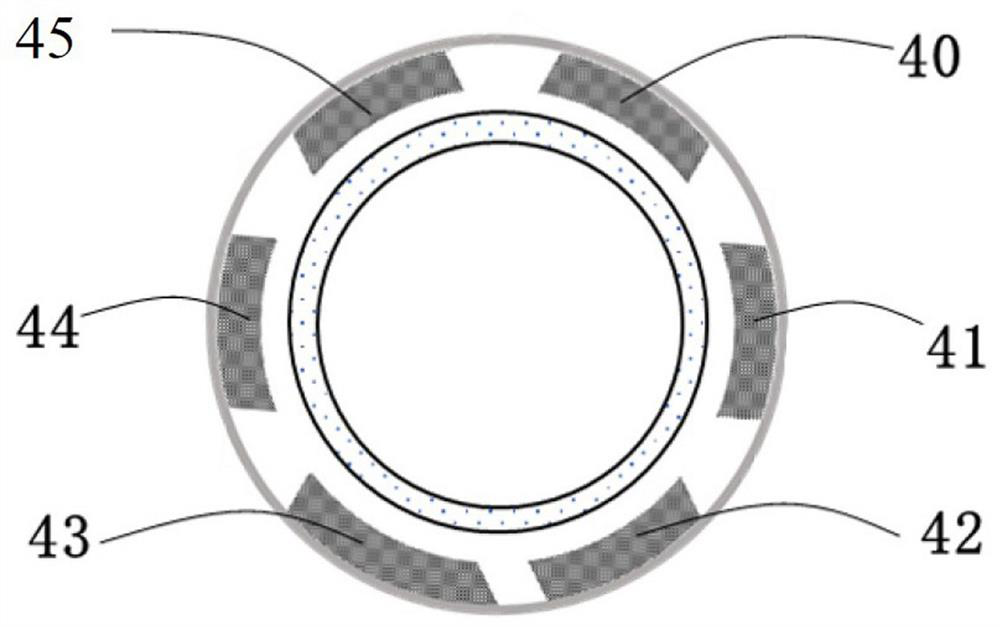

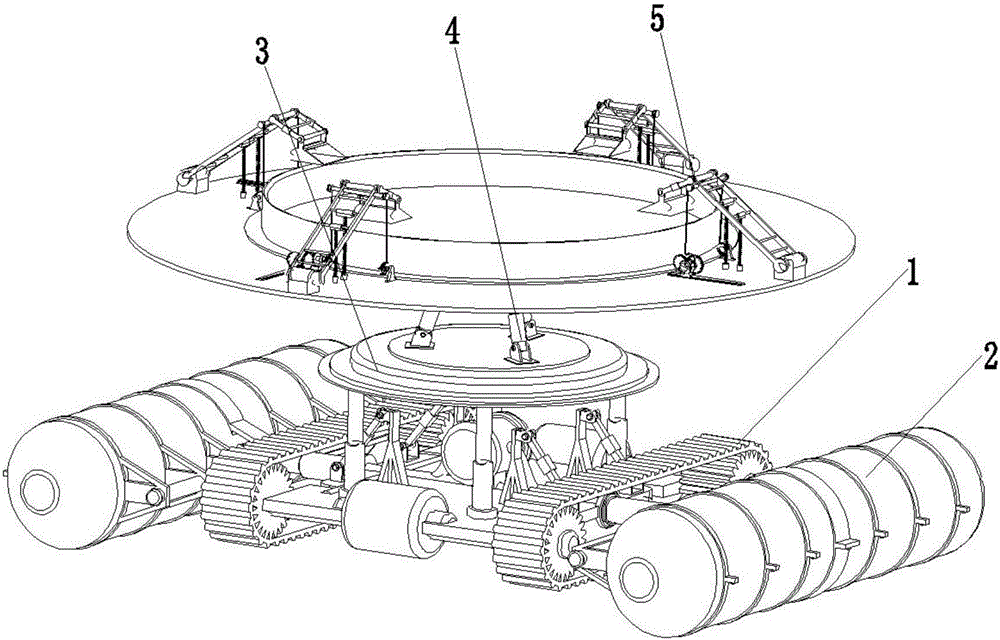

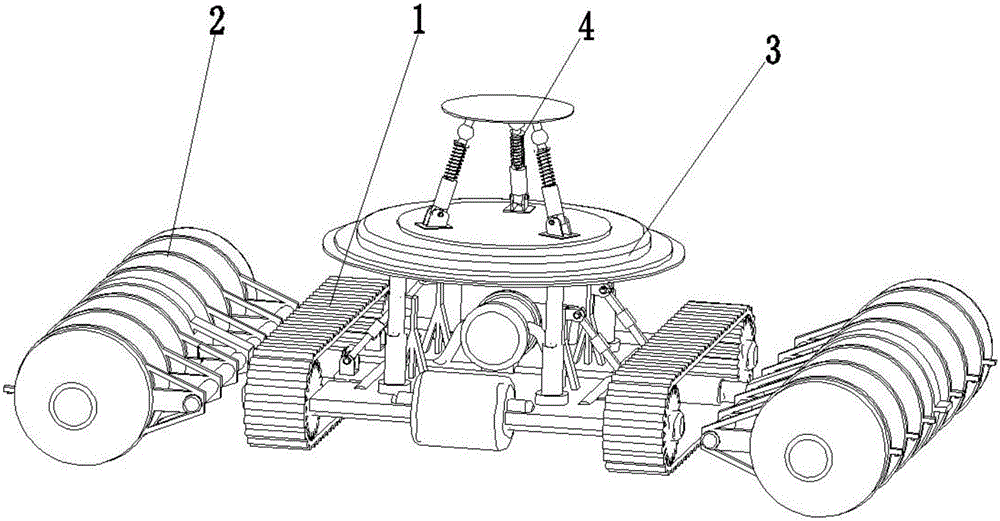

ActiveCN106069964ARealize the function of chargingTo achieve the effect of shrinking the wire ropeClimate change adaptationPisciculture and aquariaThree degrees of freedomEngineering

The invention relates to a full-intelligent fishpond feed putting integrated machine. The full-intelligent fishpond feed putting integrated machine comprises a land walking device, water surface walking devices, a lifting device, a three-degree-of-freedom parallel mechanism and a feed putting device. The water surface walking devices are located on the left side and the right side of the land walking device respectively and are connected with the land walking device, the lifting device is located over the land walking device, the lower end of the lifting device is connected with the upper end of the land walking device, the three-degree-of-freedom parallel mechanism is located between the lifting device and the feed putting device, the lower end of the three-degree-of-freedom parallel mechanism is connected with the lifting device, and the upper end of the three-degree-of-freedom parallel mechanism is connected with the feed putting device. The full-intelligent fishpond feed putting integrated machine has the land walking, water surface walking, orientation angle adjusting and feed charging and putting functions, and the automatic feed putting function of fishery breeding can be achieved; besides, the full-intelligent fishpond feed putting integrated machine is high in intelligence degree, orientation angle adjustment is convenient and flexible, the feed putting speed is high, the feed putting distance is large, and the problems that the workload of existing manual feed putting by a boat is large, high dangerousness exists, and efficiency is low are solved.

Owner:ANHUI YUNFENG AGRI DEVS CO LTD

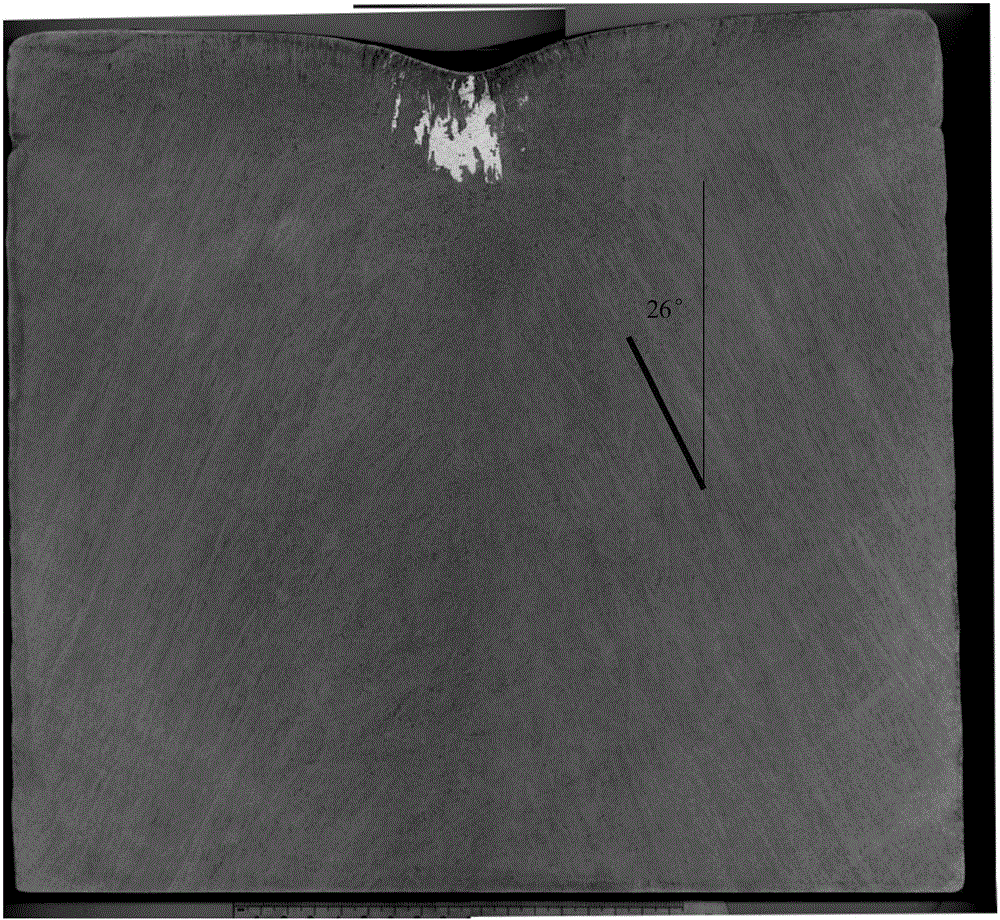

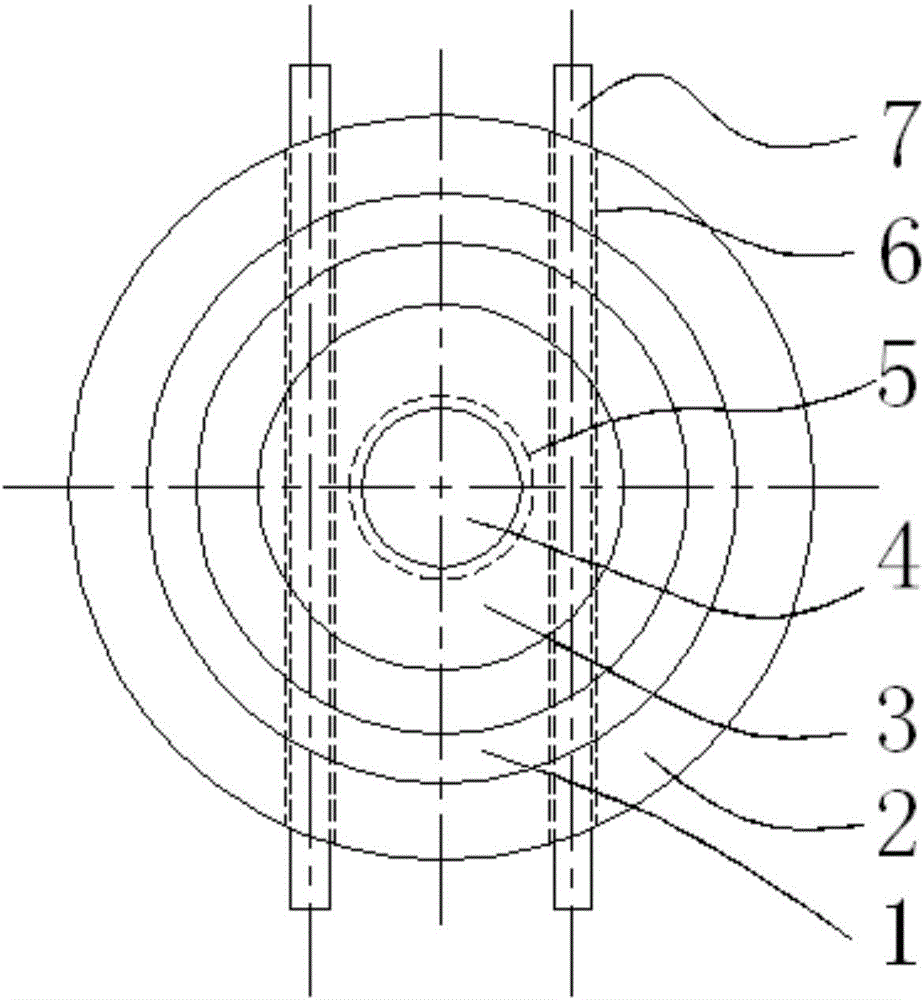

Dead head heating easily-cutting piece of large steel casting

InactiveCN103551514AReduce the cutting areaTo achieve the effect of feedingFoundry mouldsFoundry coresHeater RodEngineering

The invention relates to a dead head heating easily-cutting piece of a large steel casting. The dead head heating easily-cutting piece is characterized in that an upslope port, a lower slop port and a fracture of the easily-cutting piece are made of materials of a core, and the diameter of the upslope port of the easily-cutting piece is less than that of a dead head; an included angle between the upslope port and the upper surface of the fracture is 135-150 degrees, and an included angle between the lower slop port and the lower surface of the fracture is 120-150 degrees; the height from the lower slop port to the surface of the large steel casting is 1 / 5-1 / 4 of the thickness of the easily-cutting piece, the thickness of the fracture is 1 / 5-1 / 4 of the thickness of the easily-cutting piece, and a heating rod is positioned on a contact surface of the upslope port and the dead head and is perpendicular in the upper surface of the casting; the heating rod is made of an iron chrome aluminum electrothermal alloy material, is positioned on the contact surface of the upslope port and the dead head and is perpendicular in the upper surface of the casting, and can be reused. The dead head heating easily-cutting piece provided by the invention has the advantages that the specially-designed easily-cutting piece and a heating technique are adopted, so that the diameter of a dead head neck is greatly reduced, the section of the dead head is small, and the easily-cutting piece is easy to cut off.

Owner:SHENYANG POLYTECHNIC UNIV

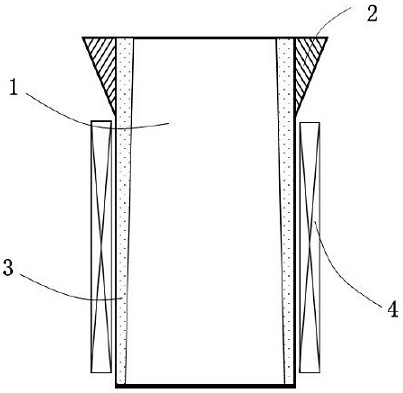

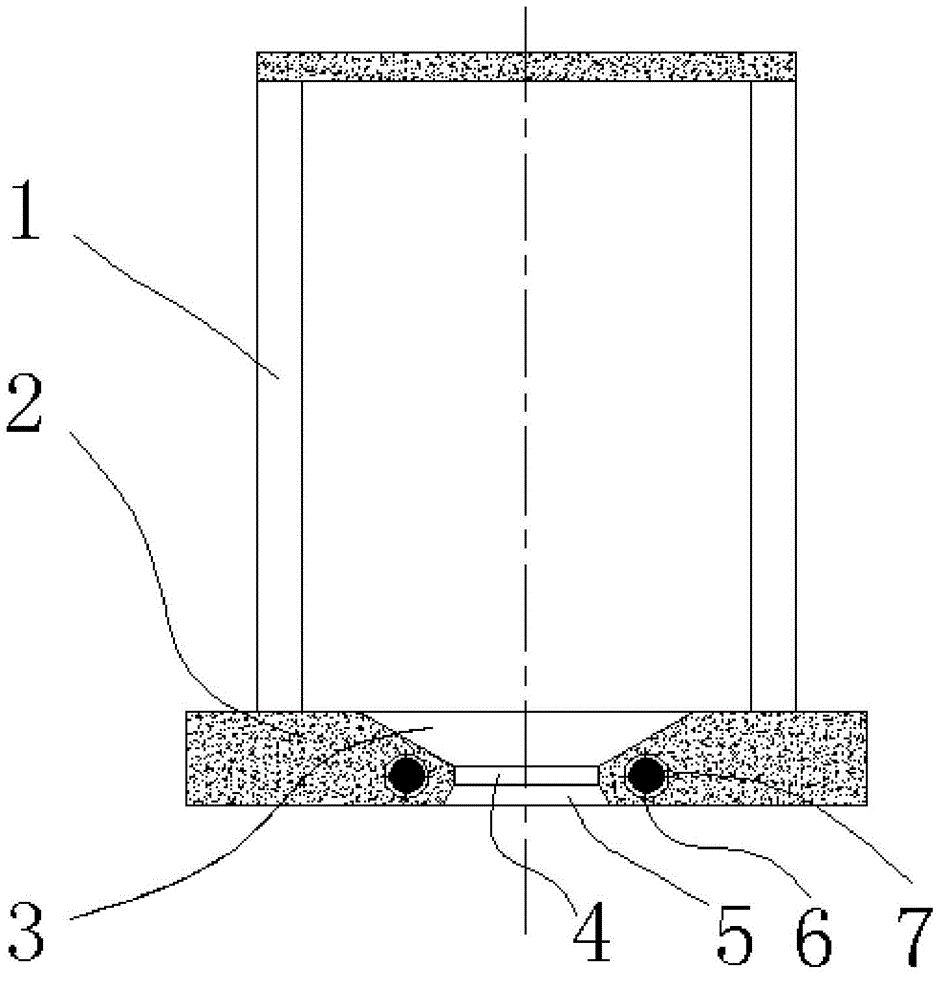

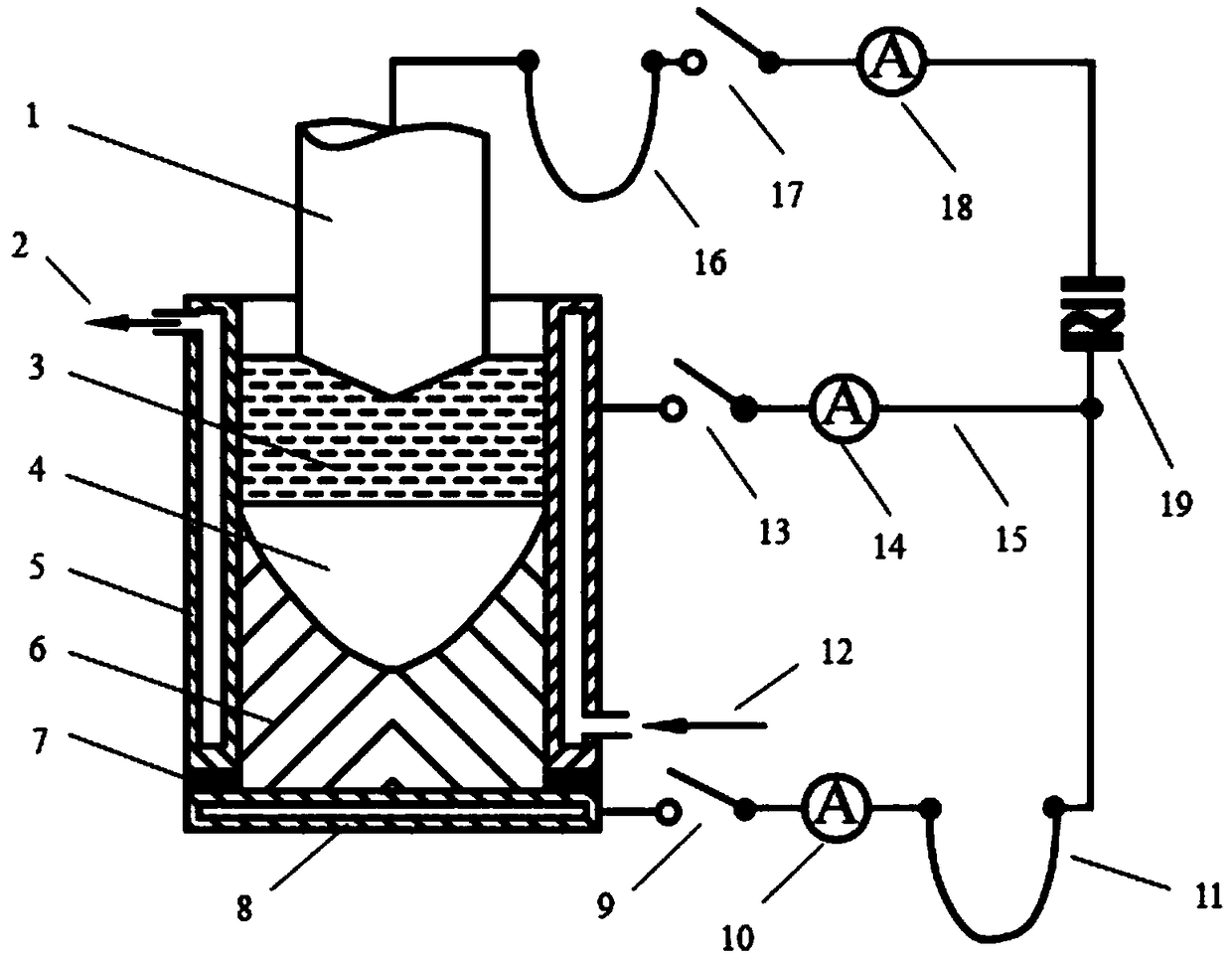

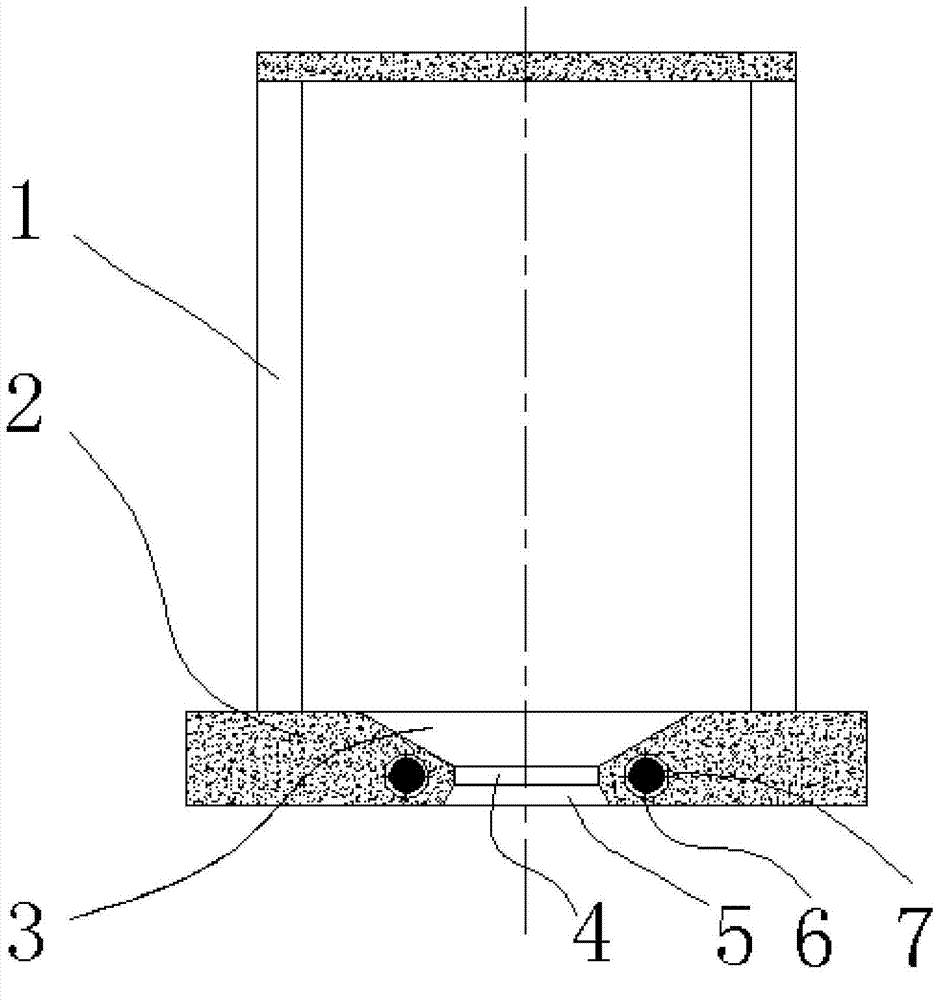

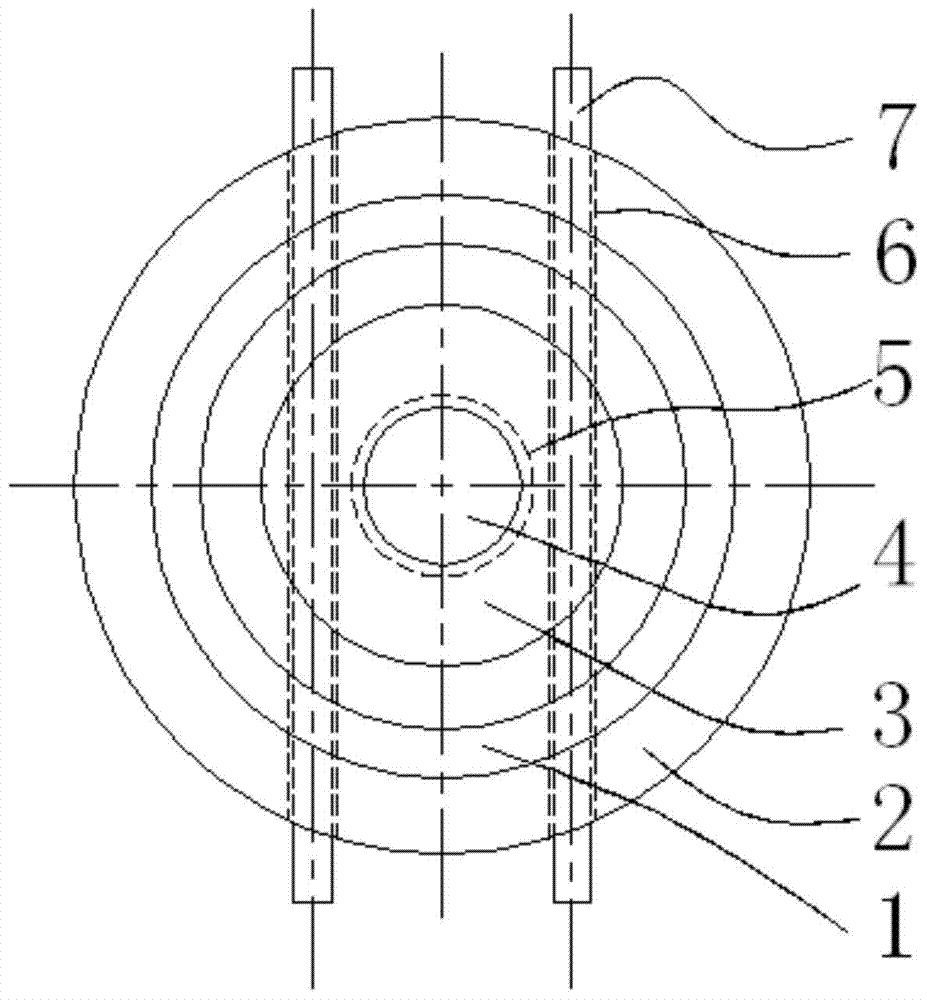

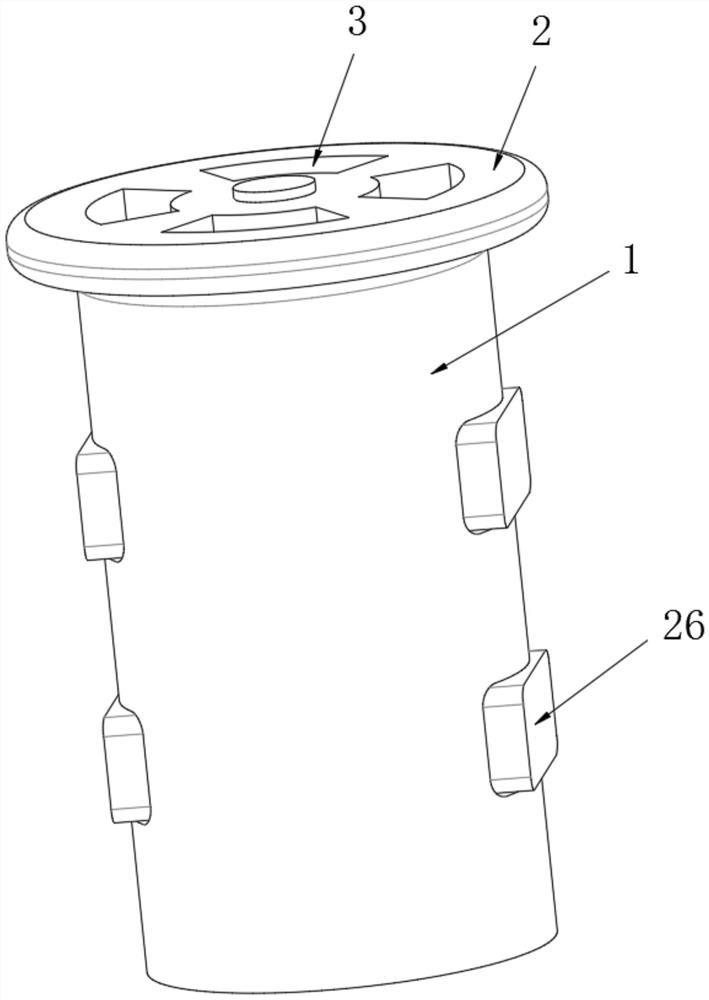

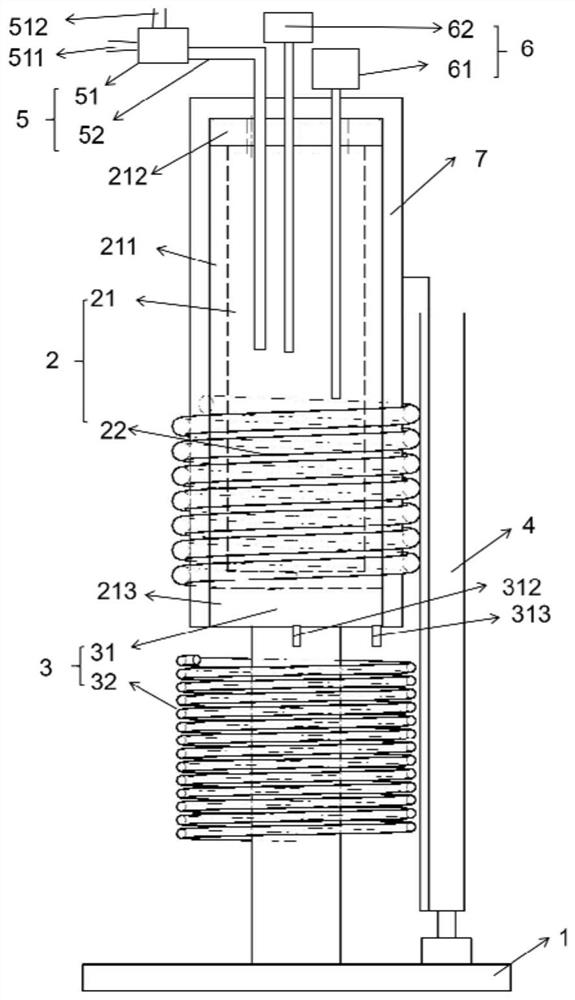

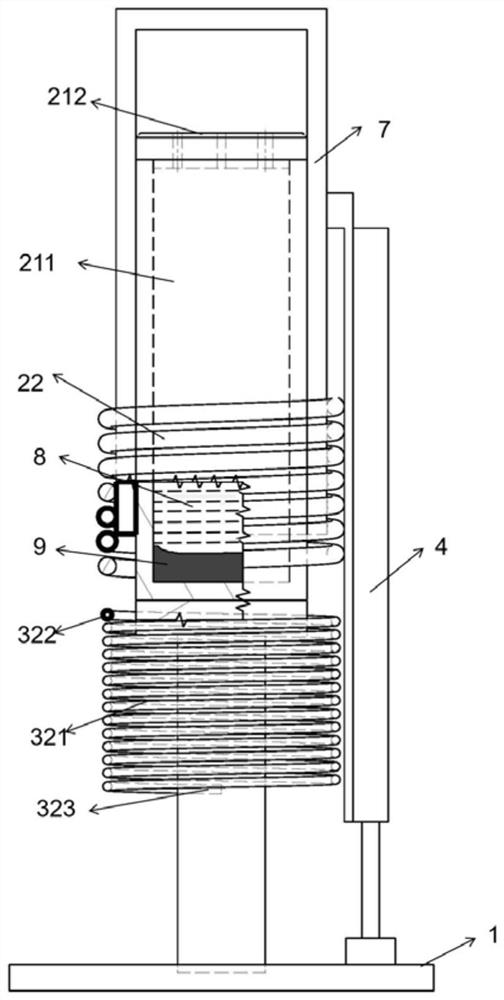

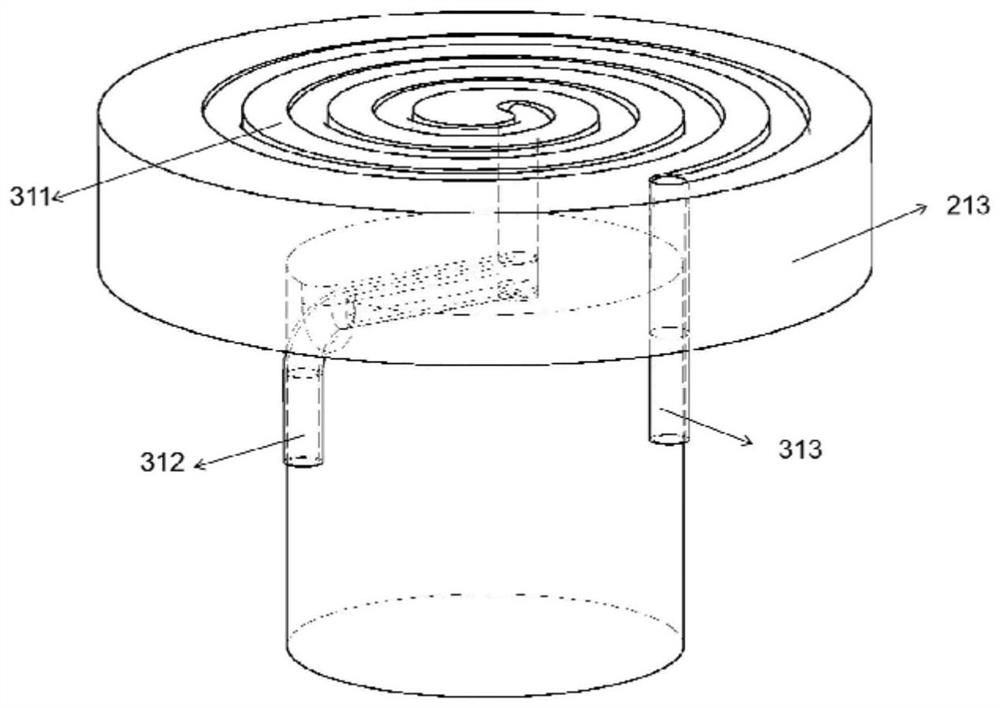

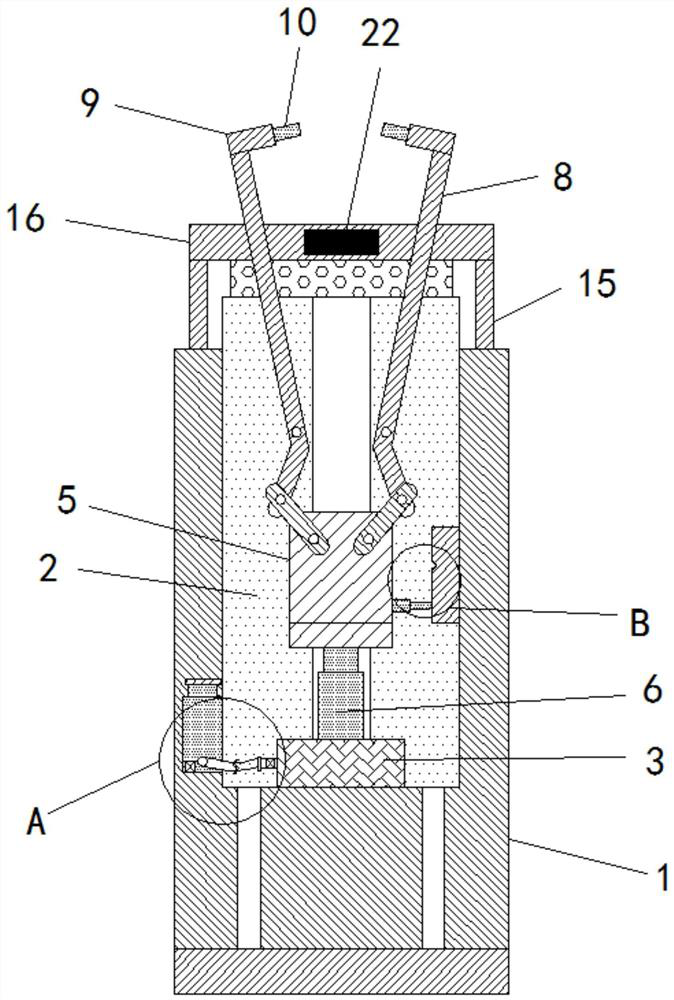

Vacuum induction melting and casting process for GH4151 alloy, and ingot mould device

The invention relates to a vacuum induction melting and casting process for GH4151 alloy, and an ingot mould device. The device comprises a mold shell (3) which is cylindrical and provided with a cavity body (1) for accommodating an alloy cast ingot, an insulated feeder (2) which is in the shape of a truncated hollow cone and connected to one end of the mold shell (3) in a sleeving manner, and an electromagnetic stirring device (4) which is cylindrical and connected to the position, where the insulated feeder is not arranged, of the mold shell (3) in a sleeving manner. According to the used process and device, segregation can be effectively reduced, internal stress in an alloy solidification process is reduced, the alloy strength is improved, and therefore cracks are prevented from being generated.

Owner:UNIV OF SCI & TECH BEIJING

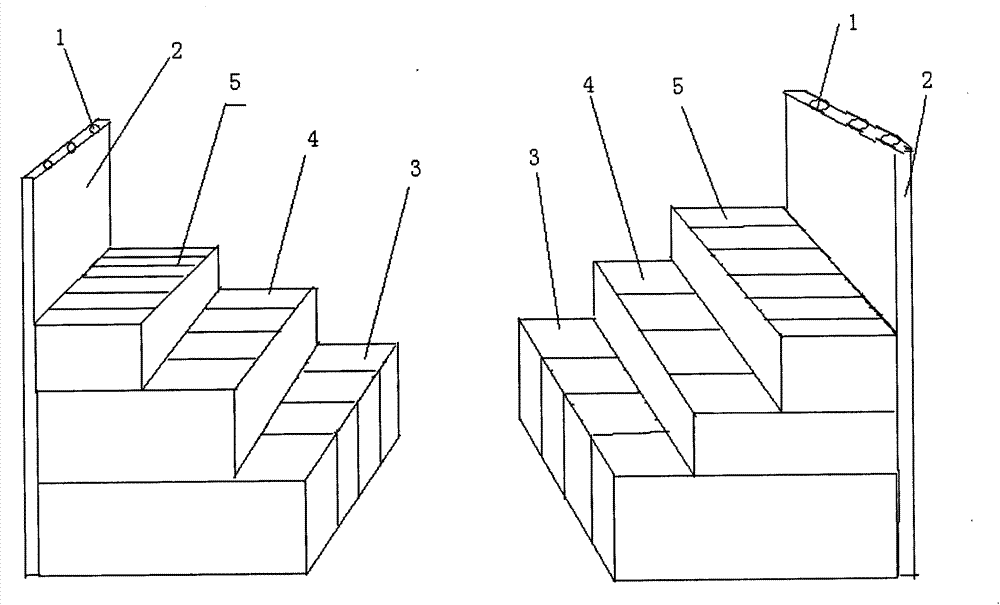

Three-dimensional bamboo rat pool

InactiveCN104255655ASave the area with suitable temperatureIncrease the number ofPisciculture and aquariaEngineeringBamboo rat

The invention discloses a three-dimensional bamboo rat pool and belongs to the technical field of animal feeding. The pool comprises a first layer, a second layer, a third layer, a blow-off pipe 1 and a wall body 2 and is characterized in that the blow-off pipe 1 penetrates the wall body 2 to the outside of a bottom exhaust wall, small pools on each layer are connected with the blow-off pipe, the small pools 3 on the first layer are 1.6m in length, 0.5m in width and 0.6m in height, the small pools 4 on the second layer are 0.8m in length, 0.6m in width and 0.5m in height, the small pools 5 on the third layer are 0.6m in length, 0.35m in width and 0.5m in height, and the small pools on each layer are distributed in bilateral symmetry. The rat pool has the advantages of saving the area of mountainous area of appropriate temperature, improving the number of fed bamboo rats in unit area and achieving the feeding effect under natural environment.

Owner:李建朋

A method for controlling the solidification structure direction of ingot by electroslag remelting of conductive mold

A method for controlling the direction of the solidification structure of an ingot by electroslag remelting in a conductive crystallizer, belonging to the field of metallurgical technology. Method: 1) Prepare high conductivity slag and then bake it; 2) Determine the filling ratio and electrode insertion depth; place the bottom pad, arc starting agent and conductive crystallizer; 3) Select the current path as power supply → self-consumption power Pole → slag material → bottom water tank → power supply, arc starting, feeding, and slag removal; after the slag material is melted, the remelting current and remelting voltage are set. During the electroslag remelting process, the current path is set by closing the switch. Control the distribution ratio of current through the crystallizer and bottom water tank, change the shape and depth of the metal molten pool, and control the direction of the solidification structure; in the later stage of remelting, the power is cut off after the electroslag remelting and feeding operation, and the remelted steel ingot is cooled. The method of the present invention uses a slag system with a high conductivity ratio to increase the tendency of axial crystallization of the solidified structure of the ingot; during the remelting process, the crystallization direction of the solidified structure of the ingot is controlled, and the prepared ingot has good surface quality.

Owner:NORTHEASTERN UNIV LIAONING

Dead head heating easily-cutting piece of large steel casting

InactiveCN103551514BReduce the cutting areaTo achieve the effect of feedingFoundry mouldsFoundry coresHeater RodAlloy

The invention relates to a heating easy-cut piece for a riser of a large-scale steel casting. The diameter of the riser, the angle between the upper groove and the upper surface of the fracture is 135-150 degrees, the angle between the lower groove and the lower surface of the fracture is 120-150 degrees, and the height of the lower groove from the surface of the casting is The thickness of the easy-cut sheet is 1 / 5-1 / 4, and the thickness of the fracture is 1 / 5-1 / 4 of the thickness of the easy-cut sheet; the heating rod is located on the contact surface between the upper bevel and the riser, and is perpendicular to the upper surface of the casting. . The heating rod is an iron-chromium-aluminum electric heating alloy heating rod, which is located on the inside where the contact surface between the upper bevel and the riser is perpendicular to the upper surface of the casting, and can be reused. Due to the use of specially designed easy-to-cut pieces and heating technology, the diameter of the riser neck can be greatly reduced, making the riser section smaller and easier to cut.

Owner:SHENYANG POLYTECHNIC UNIV

Rotary film pasting mechanism of high-performance connector accessory production device

InactiveCN112977941ARealize the effect of rotating filmAchieve the effect of removing air bubblesPackagingEngineeringWorkbench

The invention discloses a rotary film pasting mechanism of a high-performance connector accessory production device. The rotary film pasting mechanism comprises a machine body, and further comprises a fixed plate, a winch, a metal outer shell, a charge radiation plate, a positive charge bin, a metal rod, a film and a workbench, wherein the fixed plate is fixedly connected to the inner wall of the machine body, the winch is fixedly connected to the front surface of the fixed plate, the metal outer shell and the charge radiation plate are fixedly connected to the front face of the fixed plate, one end of the metal rod is fixedly connected with the surface of the metal outer shell, the other end of the metal rod is fixedly connected with the surface of the charge radiation plate, the positive charge bin is fixedly connected to the surface of the metal rod, the left end of the workbench is fixedly connected with the inner wall of the machine body, a first groove is formed in the surface of the workbench, and a suction mechanism used for sucking the film with positive charges is arranged on the surface of the workbench. The rotary film pasting mechanism has the effects of conducting film pasting and bubble removing on accessories, and the problem that in the accessory film pasting process, bubbles are difficult to remove is solved.

Owner:滁州市立鸿精密塑胶模具有限公司

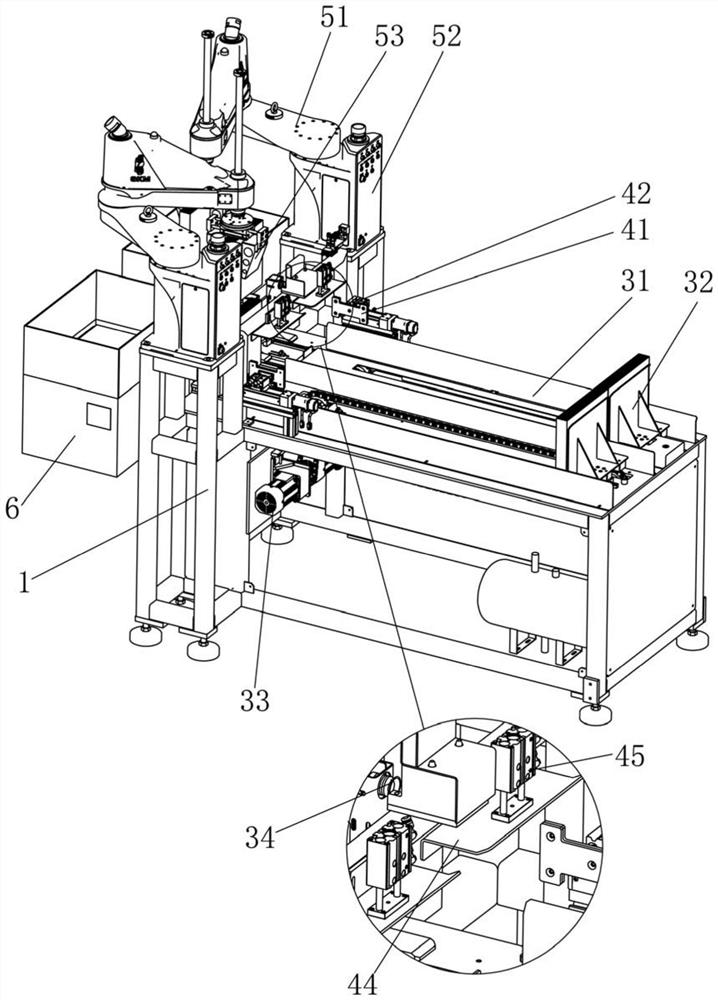

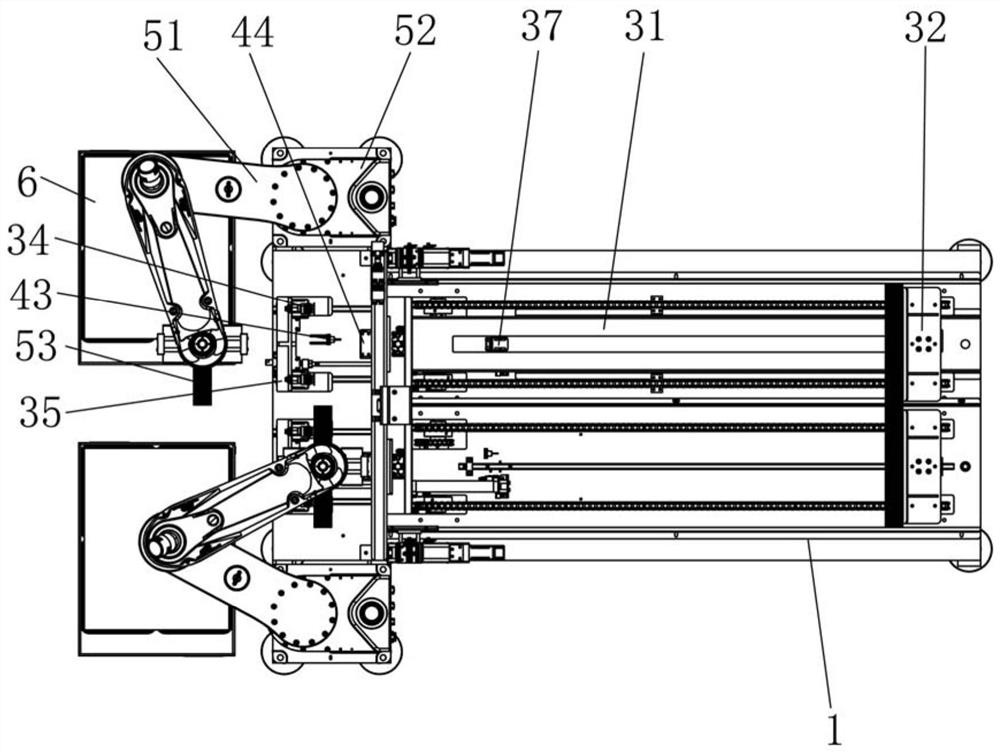

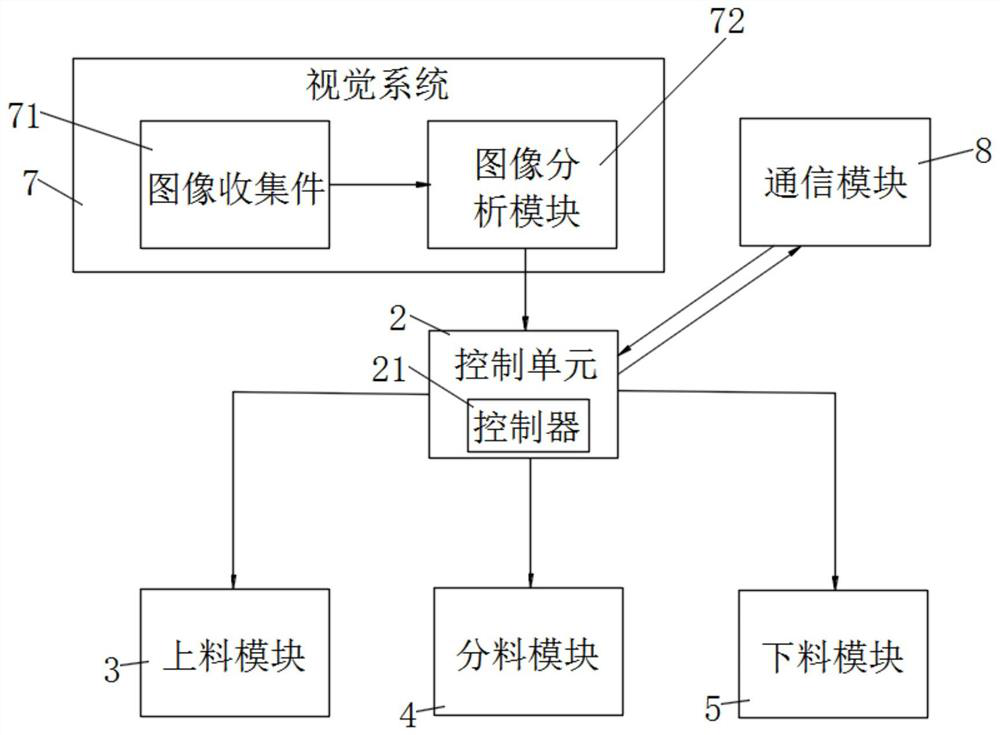

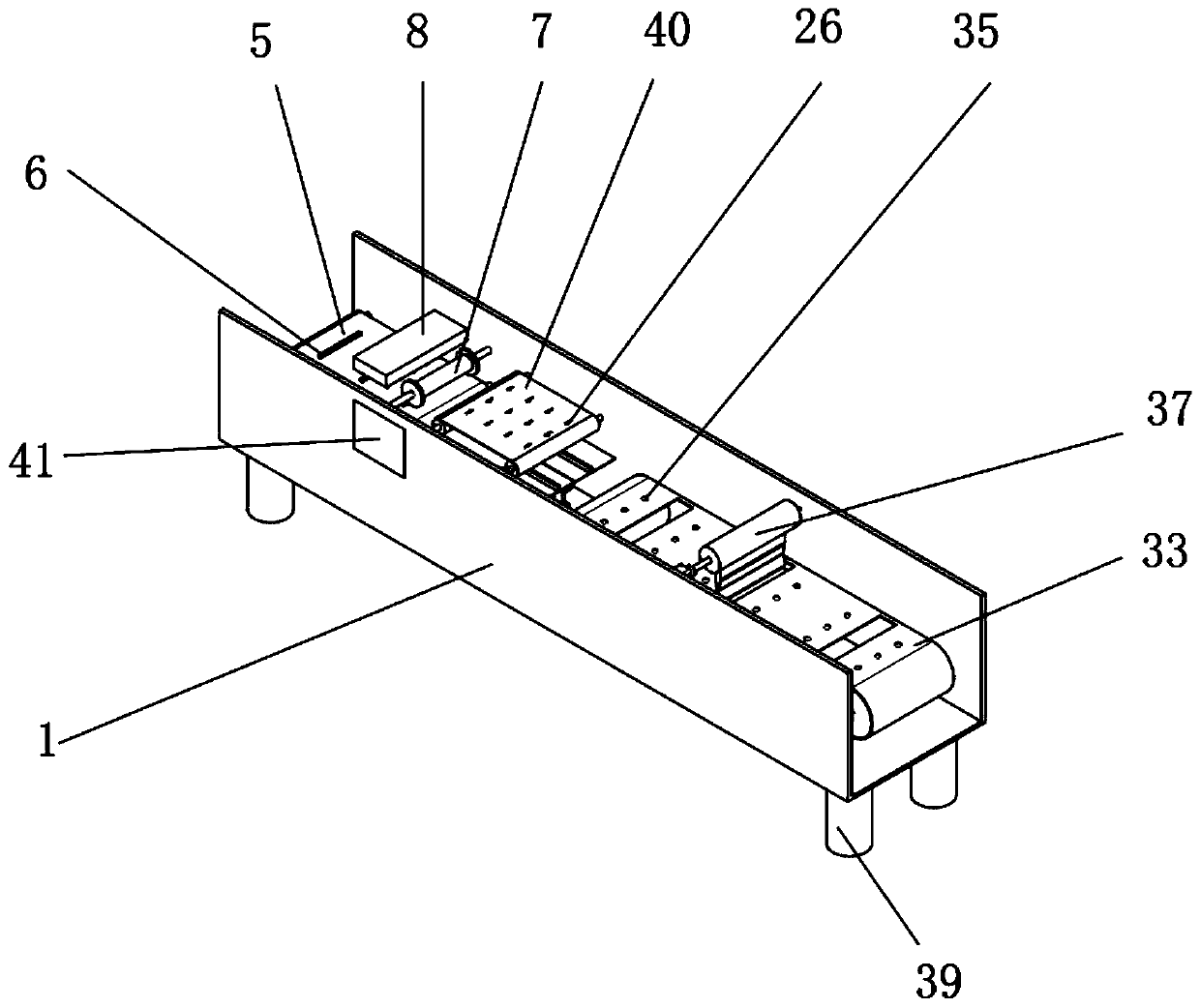

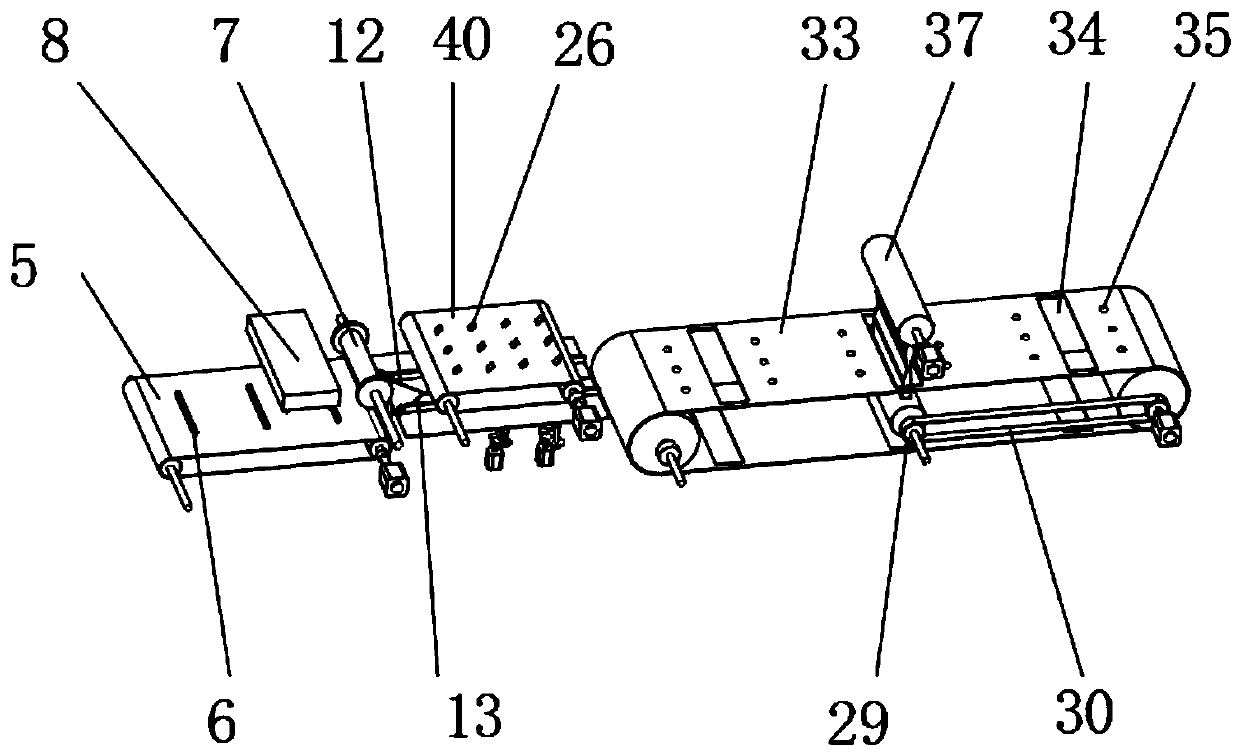

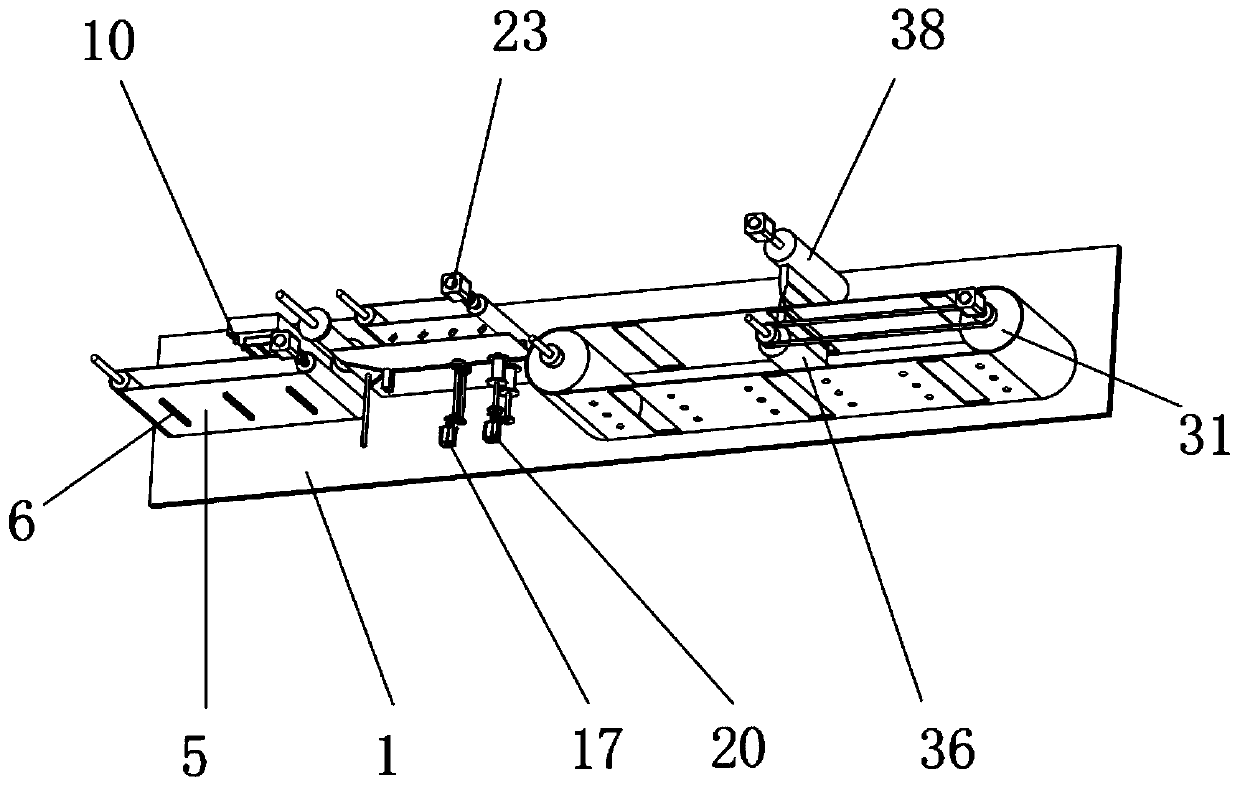

Feeding method and multi-channel feeding machine

PendingCN112707162ARealize material distributionTo achieve the effect of feedingConveyor partsEngineeringSoft materials

The invention relates to the technical field of feeding equipment, in particular to a feeding method and a multi-channel feeding machine. The feeding method sequentially comprise the following steps: S1, setting a vacuum preset value; S2, pushing the stacked materials away from a suction cup in sequence, enabling the material closest to the suction cup to abut against the suction cup to be adsorbed by the suction cup, and detecting a vacuum value in the suction cup in the pushing process; S3, when it is detected that the vacuum value in the suction cup is equal to the vacuum preset value set in the step S1, stopping pushing the stacked materials; S4, fixing the material close to the suction cup in sequence; and S5, moving the suction cup so that the material closest to the suction cup can be separated from the material secondly close to the suction cup. According to the feeding method and the multi-channel feeding machine, the suction cup is used for adsorbing materials and detecting the vacuum value in the suction cup to determine whether the materials are successfully adsorbed or not, and the suction cup is moved to separate the materials, so that the separation of the soft materials is realized, and the effect of feeding the soft materials by using automatic equipment is achieved.

Owner:QKM TECH (DONG GUAN) CO LTD

Crumb removing and sterilization integrated conveyor

InactiveCN110816956AEnsure hygieneTo achieve the effect of feedingWrapping material feeding apparatusPackage sterilisationElectric machineryProcess engineering

The invention discloses a crumb removing and sterilization integrated conveyor, and relates to the technical field of packing devices. For solving the problem of poor packing sanitation and poor fluency, the conveyor specifically comprises a main body, wherein four supporting legs are welded to the outer wall of the bottom surface of the main body, and a feeding area, a bottom sealing area and anedge sealing area are arranged in the main body. According to the conveyor, through arranging a feeding motor and a feeding conveyor belt, the feeding effect can be achieved; through arranging a negative pressure pipeline and a crumb suction port, the effect of removing breadcrumbs can be achieved; through arranging an ultraviolet sterilizing lamp, passing breads can be sterilized, and the sanitation of the breads is guaranteed; by arranging a film collecting roller, cut packing film waste can be subjected to film rolling and film collecting; and by arranging a propelling motor and a bottom sealing conveyor belt, after the breads is conveyed to the bottom sealing area through the feeding conveyor belt, the breads are wrapped up in a packing film while the bread continues to be conveyed bythe bottom sealing conveyor belt.

Owner:湖南省爱尚乐心食品有限公司

Quantitative fertilization device for agricultural production

PendingCN112753336ATo achieve a fixed connectionGood disassembly effectFertiliser distributersImpellerAgricultural science

The invention discloses a quantitative fertilization device for agricultural production. The device comprises a lower shell and a feed hopper, the feed hopper is mounted at the top end of the lower shell, the interiors of the feed hopper and the lower shell are communicated, a power mechanism is mounted on the feed hopper, a feed inlet is formed at the position, located at one side of the power mechanism, of in the feed hopper, a discharge shell is mounted on the surface of the lower shell, a main shaft body is installed in the lower shell, and a material distributing mechanism is installed on the surface of the main shaft body. The material distributing mechanism comprises a propelling shaft body and a feeding impeller, the feeding impeller is installed on the main shaft body, the propelling shaft body is installed in the main shaft body, and an adjusting sleeve is installed on the surface of the propelling shaft body. By arranging a series of structures, the quantitative fertilization device for agricultural production can be convenient to disassemble and clean, meanwhile, stirring and directional feeding operation of fertilizer can be facilitated, and by means of the telescopic effect of an electric push rod, the fertilizer feeding rate is changed in a mode of shielding the impeller, and the quantitative fertilization effect is achieved.

Owner:天津周凤和农作物种植专业合作社

Fruit food crushing equipment for small breeding of animal husbandry

PendingCN114471861AAchieve broken effectOperation saves time and effortGrain treatmentsAnimal scienceZoology

The invention relates to crushing equipment, in particular to fruit food crushing equipment for small breeding of animal husbandry. The fruit food crushing equipment for small breeding of the animal husbandry is automatic in discharging and crushing and high in crushing efficiency. Fruit food crushing equipment for small breeding of animal husbandry comprises a bottom plate and a support, and the support is arranged on the bottom plate; the rotating mechanism is arranged on the bracket; the two crushing cutters are arranged on the rotating mechanism; and the discharging mechanism is arranged on the bracket. According to the fruit food crushing device, a crushing cutter is driven to rotate, then people place fruit food into the box body, the rotating crushing cutter crushes the fruit food, the crushing effect is achieved, and the operation saves time and labor; by starting an air cylinder, an air cylinder telescopic rod drives a first connecting block to move backwards, so that a baffle is driven to move backwards, people collect crushed food blocks on the lower side of the box body, and the discharging effect is achieved.

Owner:陈飞

Vacuum package detection device capable of checking air tightness and automatically feeding

InactiveCN113686492ATo achieve the effect of feedingLarge capacityFluid-tightness measurementMechanical audible signallingEngineeringMachine

The invention relates to the technical field of vacuum packaging, and discloses a vacuum package detection device capable of checking air tightness and automatically feeding. The vacuum package detection device comprises a machine shell, wherein a first long plate is slidably connected to the left side of the machine shell, a fixed contact is arranged at the bottom part of the first long plate, a rotating wheel is arranged at the bottom part of the fixed contact, a first push rod is fixedly connected to the upper portion of the rotating wheel, a movable contact is fixedly connected to the upper end of the first push rod, a second push rod is fixedly connected to the right side of the rotating wheel, and a movable rod is arranged on the left side of the rotating wheel. According to the vacuum package detection device capable of checking air tightness and automatically feeding, the rotating wheel drives the movable rod to rotate through the second push rod, so that a clamping block is separated from the position between a first stop block and the movable rod, the first long plate drives an object to slide leftwards under the action of a spring, and meanwhile, the rotating wheel extrudes the clamping block through a first push rod, so that the first long plate drives the object to slide rightwards, and the rotating wheel drives the object to slide left and right through the first long plate; therefore, the feeding effect is achieved.

Owner:达通达顺(深圳)运输服务有限公司

Chain type feeder conveniently transporting different materials

InactiveCN108016821AEasy to transportSolve the problem of difficult transportation of different materialsConveyorsChain typeMaterial transport

The invention discloses a chain type feeder conveniently transporting different materials, and relates to the technical field of chain type feeders. The chain type feeder conveniently transporting thedifferent materials comprises a first supporting column. The top of the back face of the first supporting column is movably connected with a first rotation shaft. The end, away from the first supporting column, of the first rotation shaft is movably connected with a second supporting column. A first gear is fixedly connected to the outer side of the first rotation shaft. The right side of the first supporting column is fixedly connected with a first transverse plate. The right side of the first transverse plate is fixedly connected with a supporting table. The top of the supporting table is fixedly connected with a motor. An output shaft of the motor is fixedly connected with a second rotation shaft. According to the chain type feeder conveniently transporting different materials, throughthe structural design of the motor, the first gear, the second gear, the first rotation shaft, the second rotation shaft, a conveying chain, a gear row and a feeding box, the problem that a chain type feeder difficultly transports different materials is solved.

Owner:无锡市内河装卸机械有限公司

Sand treatment equipment and method in foundry industry

InactiveCN114535503AAvoid incomplete screeningTo achieve the effect of feedingMould handling/dressing devicesFoundryEngineering

The invention relates to the technical field of sand treatment, and discloses sand treatment equipment in foundry industry, which comprises a shell, a top cover is fixedly mounted at the top end of the shell, a feeding hole is formed in the top cover, a transverse plate is slidably connected in the top cover, electromagnets are fixedly mounted on the left side and the right side of the transverse plate in the top cover, and the electromagnets are fixedly mounted on the left side and the right side of the transverse plate in the top cover. According to the sand treatment equipment and method in the casting industry, on-off of the control switch is automatically controlled through the weight of remaining materials on the surface of the buffer plate, then opening and closing of the feeding opening are controlled, and the effect of automatically supplementing materials into the shell is achieved; and then the materials in the shell are screened out through the discharging opening with the gradually-reduced cross section area and are screened out again under the action of the stirring rod and the rotating rod, so that the impurities large in size and mass are gradually screened out, and the phenomenon that screening is not thorough due to the fact that the impurities are screened out once is avoided.

Owner:杨谨铭

A feed feeding device that automatically quantitatively discharges feed according to poultry size

ActiveCN112088804BPrecise supplyTo achieve the effect of feedingFood preservationAvicultureAnimal sciencePigeon breast

The invention relates to the technical field of poultry feeding, and discloses a feed feeding device for automatic quantitative discharge according to poultry body size, including a return spring, the top of the return spring is movably connected with a landing frame, and the left side of the elevating rod is movably connected with a Transmission gear, the left side of the transmission gear is movably connected with a tooth plate, the interior of the tooth plate is movably connected with a one-way spring, and the top of the tooth plate is movably connected with a storage bin, which will drive the transmission gear clockwise when the lifting rod descends The rotation drives the support plate on the top of the tooth plate to move upward, and then drives the feed inside the storage bin to move upward, and drives the crushing blade to rotate to crush the feed and transport the crushed feed to the top of the tooth plate. The pulverized feed finally moves into the feeding bin through the one-way hole for the pigeons to eat, thereby achieving the effect of automatically quantitatively discharging the feed according to the size of the pigeons.

Owner:SICHUAN WANGDA FEED

A seeding machine covered with water mist film when sowing

ActiveCN112690064BTo achieve the effect of feedingTo achieve the effect of intermittent sprayDibble seedersWatering devicesSeederAgricultural science

The invention discloses a seeder for adding water mist film when sowing, which comprises a frame body, a roller, a mounting frame, a material storage tank and a feeding port. It is fixedly connected to the upper side of the middle part of the frame body, the storage tank is fixedly connected to the upper end of the installation frame, the feeding port is fixedly connected to the upper end of the storage tank, and the side of the installation frame is fixedly connected to a water storage tank. The upper end of the water storage tank is fixedly connected with a water injection port, and the inside of the installation frame is fixedly connected with a guide groove at the lower side of the material storage tank. When the invention is in use, the effect of intermittent spraying is achieved through the cooperative use of structures such as water delivery pipes and elastic pipes, and the effect of stable sowing is achieved through the cooperative use of structures such as movable rods and storage blocks. The combination of water holes and other structures achieves the effect of full film coating.

Owner:聊城市彩烁农业科技有限公司

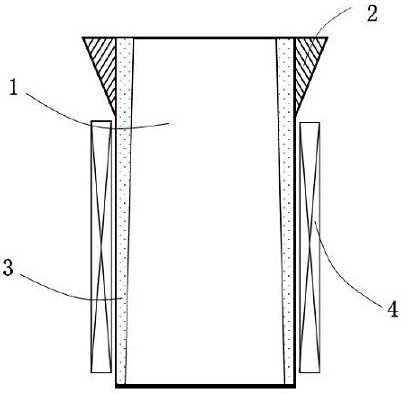

A production device and method for a large-size oxygen-free copper ingot applied to a target

ActiveCN110629180BHigh densityGuaranteed DensityVacuum evaporation coatingSputtering coatingInsulation layerHigh density

The invention provides a production device for large-scale high-purity and high-density oxygen-free copper ingots applied to targets. The device includes a lifting mechanism. During the production process of oxygen-free copper ingots, after the raw copper is melted, the lifting mechanism can drive The intermediate frequency coil, insulation layer and air-cooling components move upward to realize the directional solidification of copper liquid from bottom to top. During the solidification process of molten copper, since the cooling mechanism is below the crucible assembly, and the air cooling assembly moves slowly and uniformly from bottom to top, the molten copper starts to solidify from the bottom of the crucible, the bottom of the crucible is solid copper, and the upper part is un The cooled liquid copper has the phenomenon that solid and liquid exist at the same time, ensuring that there is always liquid copper on the surface of solid copper or copper that is being solidified. When defects such as holes occur in the solid copper at the bottom, the copper liquid on the upper part can be replenished in time. To achieve the effect of shrinkage, reduce the internal defects of copper ingots, increase the density of copper ingots, and obtain oxygen-free copper ingots with high purity, high density, large size and small defects.

Owner:河北冠靶科技有限公司

An auxiliary device for cable recovery and stripping used in intelligent transportation projects

ActiveCN111244833BTo achieve the effect of feedingQuick peelBasic electric elementsApparatus for removing/armouring cablesSolenoid valveStructural engineering

The invention relates to the technical field of cable recycling, and discloses a cable recycling and peeling auxiliary device used in intelligent transportation projects. There is a pumping device, the left side of the pumping device is provided with a solenoid valve, the front of the sub-board is interactively connected with a movable plate, a spring tube is arranged between the movable plate and the pumping device, and a spring rod is arranged on the right side of the movable plate , the upper part of the movable plate is provided with a connecting rod extending to the sub-plate. The auxiliary device for cable recovery and peeling used in intelligent transportation projects uses a pump to inflate the spring tube to move the movable plate, which in turn causes the ring knife to cut the cable, and cooperates with the movable plate to drive the spring rod into the groove. When the solenoid valve is activated, the spring tube 2 will extend to make the ring knife pull down the cable, and then cooperate with the nozzle to spray paint to remove the residue, so as to achieve the effect of quick peeling and removal of residue.

Owner:蓝光元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com