Flowerpot batch soil covering device for potted plants

A batch and soil-covering technology, which is applied in the field of batch soil-covering device for flower pots for potted plants, can solve the problems of low work efficiency, lumpy soil, inconvenient planting, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

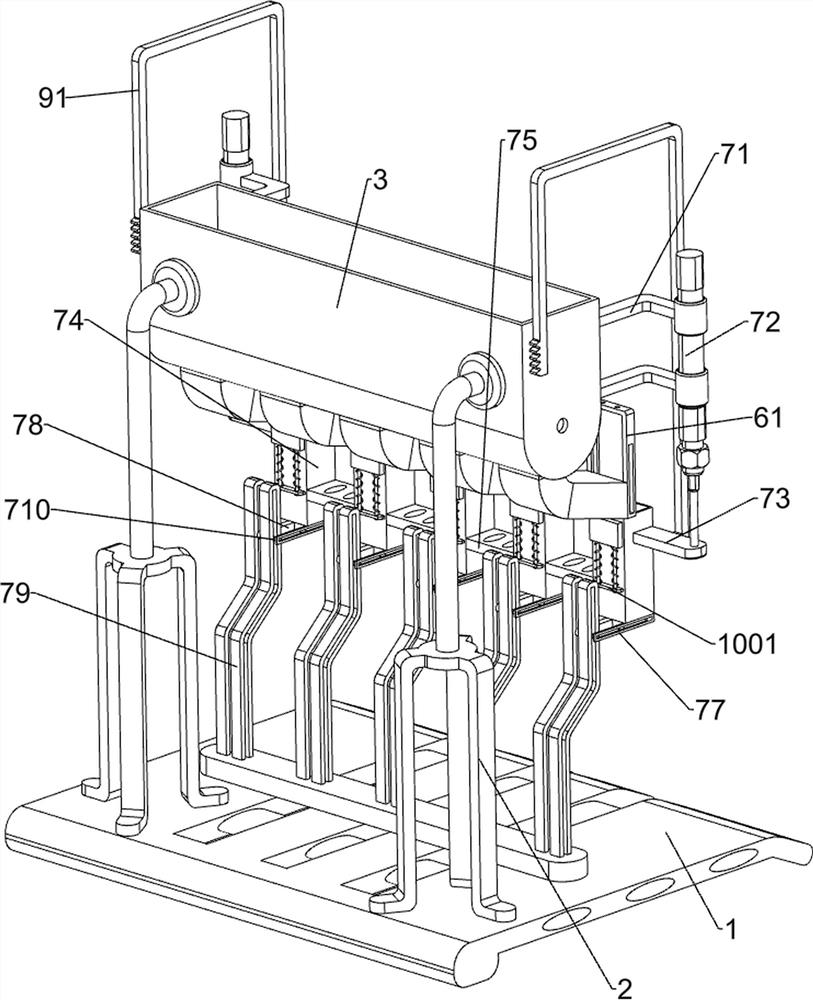

[0033] A kind of flower pot bulk covering device for potted plants, such as Figure 1-4 As shown, it includes a bottom frame 1, a first fixed frame 2, a material box 3 and a support frame 4. The left and right sides of the top of the bottom frame 1 are connected with the first fixed frame 2, and the two first fixed frames 2 are connected. There is a material box 3, and the bottom of the material box 3 is evenly spaced with a plurality of discharge ends. A pulverizing mechanism 5 and a blocking mechanism 6 are provided.

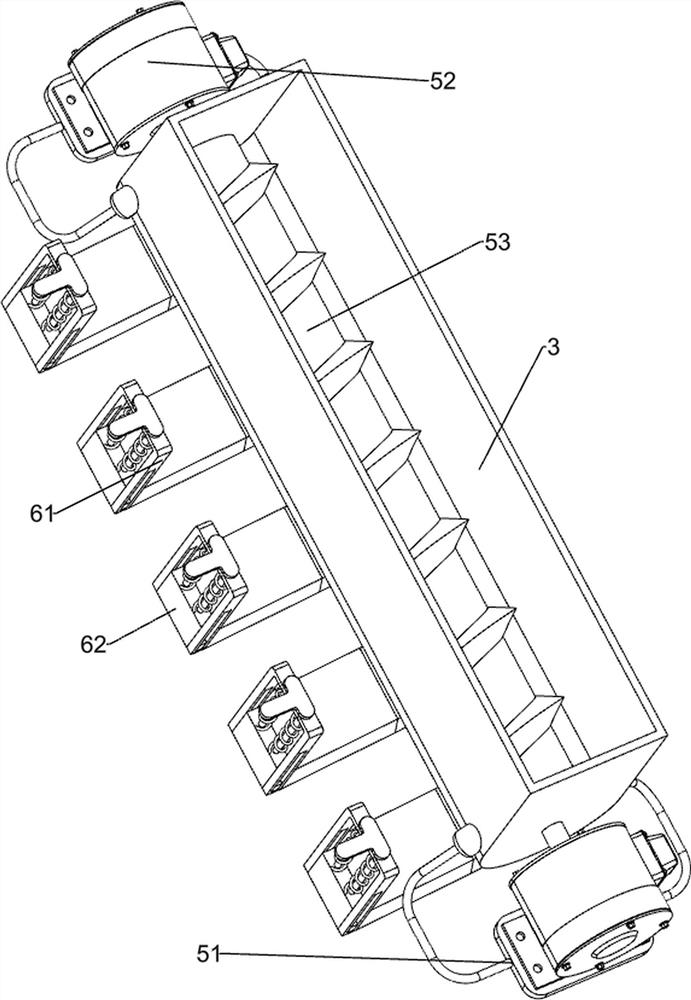

[0034] The crushing mechanism 5 includes a second fixed mount 51, a servo motor 52 and a stirring rod 53, and the left and right sides of the material box 3 are connected with a second fixed mount 51, and the second fixed mount 51 is equipped with a servo motor 52, which is a material box 3. A stirring rod 53 is rotatably connected to the top, and both sides of the stirring rod 53 are connected to the output shafts of two servo motors 52 respectively.

[003...

Embodiment 2

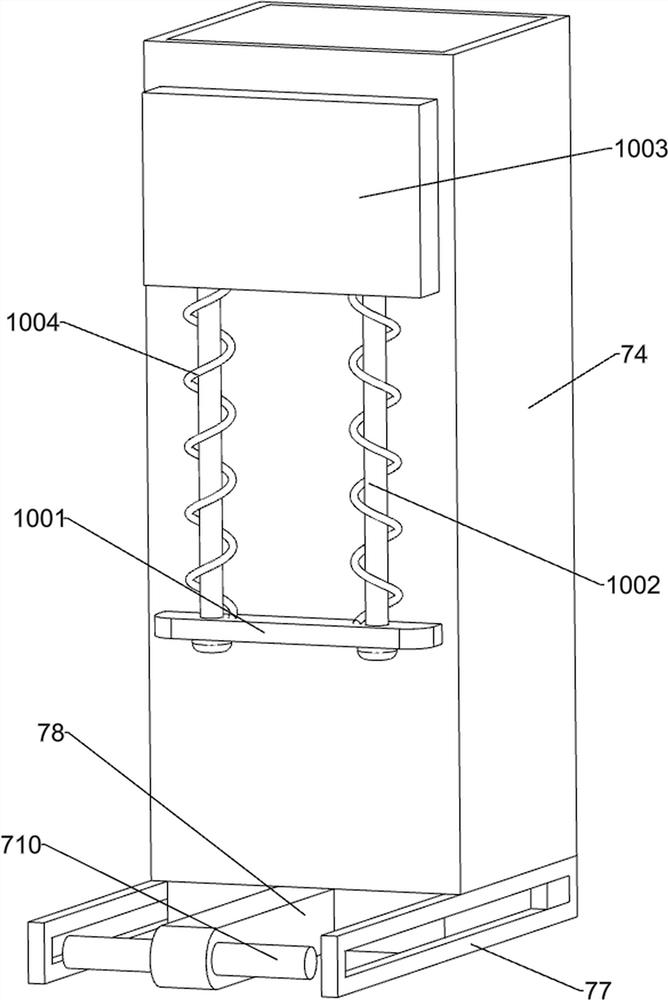

[0038] On the basis of Example 1, such as Figure 5-6Shown, also includes unloading mechanism 7, and unloading mechanism 7 includes the 3rd fixed frame 71, cylinder 72, first fixed plate 73, receiving rack 74, the second fixed plate 75, fixed rod 76, the second guide Sliding frame 77, the second material blocking plate 78, the 3rd guide carriage 79 and guide slide bar 710, are all connected with the 3rd fixed mount 71 on the left and right sides of material box 3, and cylinder 72 is installed on the 3rd fixed mount 71, The telescopic rods of the two cylinders 72 are connected with a first fixed plate 73, and a plurality of receiving racks 74 are evenly spaced between the two first fixed plates 73, and the receiving rack 74 cooperates with the first material blocking plate 62, The rear side of the material receiving frame 74 is provided with a material inlet, and the material inlets of a plurality of material receiving frames 74 are respectively aligned with a plurality of disc...

Embodiment 3

[0043] On the basis of Example 2, such as Figure 6 and Figure 8 As shown, it also includes a flip mechanism 9, and the flip mechanism 9 includes a third rack 91, a second support block 92, a second connecting shaft 93, a cover plate 94, a torsion spring 95 and a third spur gear 96, the first fixed The plate 73 is connected with a third rack 91, and is connected with two second support blocks 92 at the upper part of the rear side of the material box 3, and a second connecting shaft 93 is connected in rotation between the two second support blocks 92, and the second connection A cover plate 94 is connected to the shaft 93, a torsion spring 95 is connected between the cover plate 94 and the second support block 92, a third spur gear 96 is connected to both sides of the second connection shaft 93, and the two third spur gears 96 are respectively Engages with two third racks 91 .

[0044] The first fixed plate 73 can drive the third rack 91 to move up and down when moving up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com