Machining equipment for ultrathin special-shaped copper pipe

A processing equipment and special-shaped technology, which is applied in the direction of metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of time-consuming and labor-intensive, reducing the production efficiency of processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

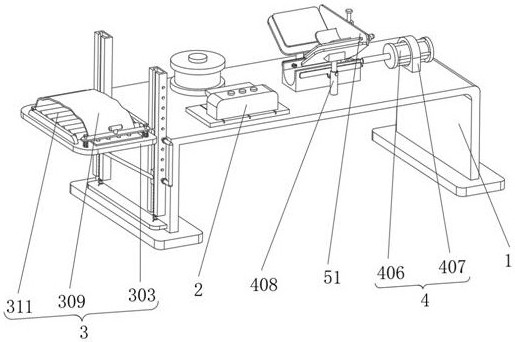

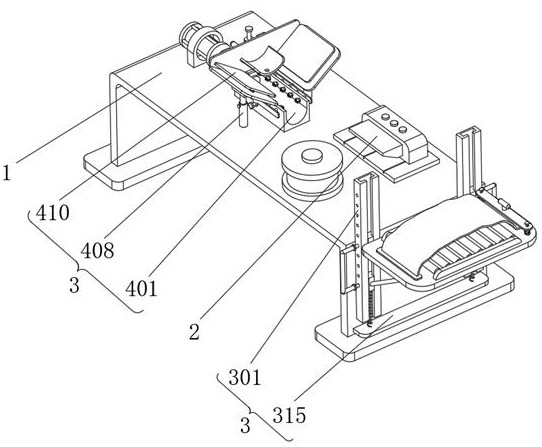

[0030] Example 1, such as Figure 1-8 As shown, the present invention provides a processing equipment for ultra-thin special-shaped copper tubes, including a processing table 1 and an adjusting device 3 , the surface of the processing table 1 is fixedly mounted with a driver 2 , and the surface of the processing table 1 is provided with an adjusting device 3 .

[0031] Let's talk about the specific settings and functions of its regulating device 3, limit device 4 and auxiliary device 5 in detail below.

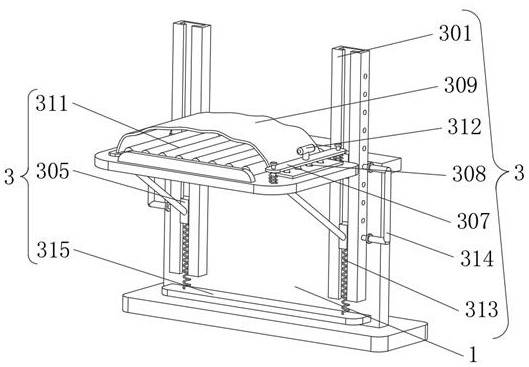

[0032] Such as image 3 and Figure 4 As shown, the adjustment device 3 includes two slide rails 301, and the two slide rails 301 are uniformly fixedly connected to the surface of the processing table 1, and the inner wall of the slide rail 301 is slidably connected with a first slider 302, and the two first sliders 302 are away from One end of the inner wall of the slide rail 301 is fixedly connected with a rectangular plate 303, and the lower surface of the rectangular pla...

Embodiment 2

[0038]Embodiment 2, on the basis of Embodiment 1, when processing the copper pipe, first rotate the two screw rods 411, the two screw rods 411 will drive the moving plate 403 to move by means of the threads, and the moving plate 403 will drive the sliding rod 402 to move, and the sliding rod 402 will move. The rod 402 drives the pulley 404 to move, achieving the effect of adjusting the distance between the pulleys 404 in the limit block 401. After adjusting the position of the pulley 404, turn the switch of the telescopic rod 408 to make the telescopic rod 408 drive the top plate to move up and down , the top plate drives the buffer plate 410 to move up and down by means of the third spring 409 to achieve the effect of adjusting the height of the buffer plate 410, and then put the copper tube to be processed directly on the buffer plate 410, the copper tube will give the buffer plate 410 a pressure, buffer The plate 410 will receive the elastic force of the third spring 409 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com