Crumb removing and sterilization integrated conveyor

The technology of a conveyor and a main body is applied in the field of integrated crumb removal and sterilization conveyors, which can solve the problems of inability to guarantee the hygiene of bread and poor versatility, and achieve the effects of increasing conveying stability, ensuring hygiene, and avoiding the wrong position of sealing knives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

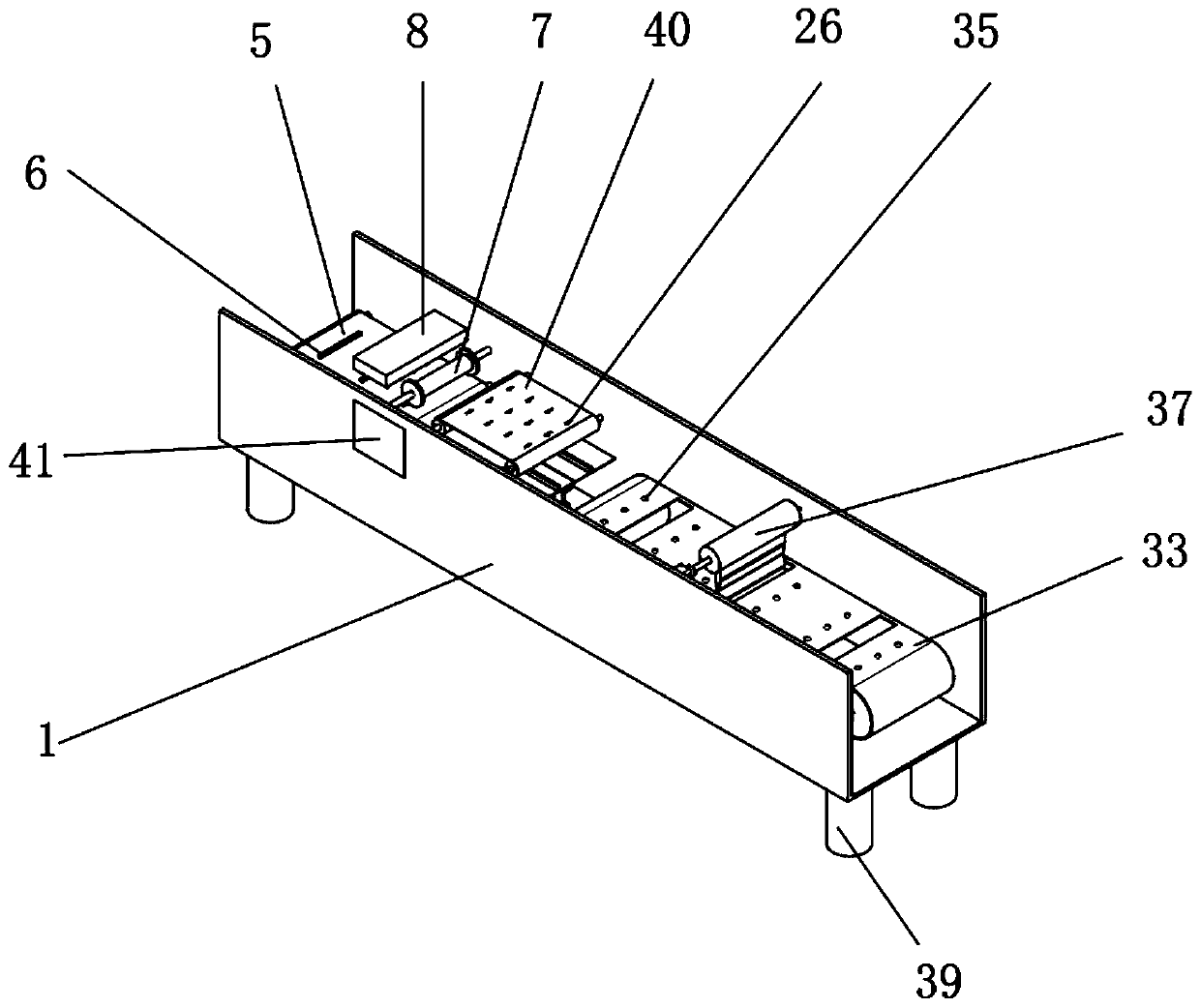

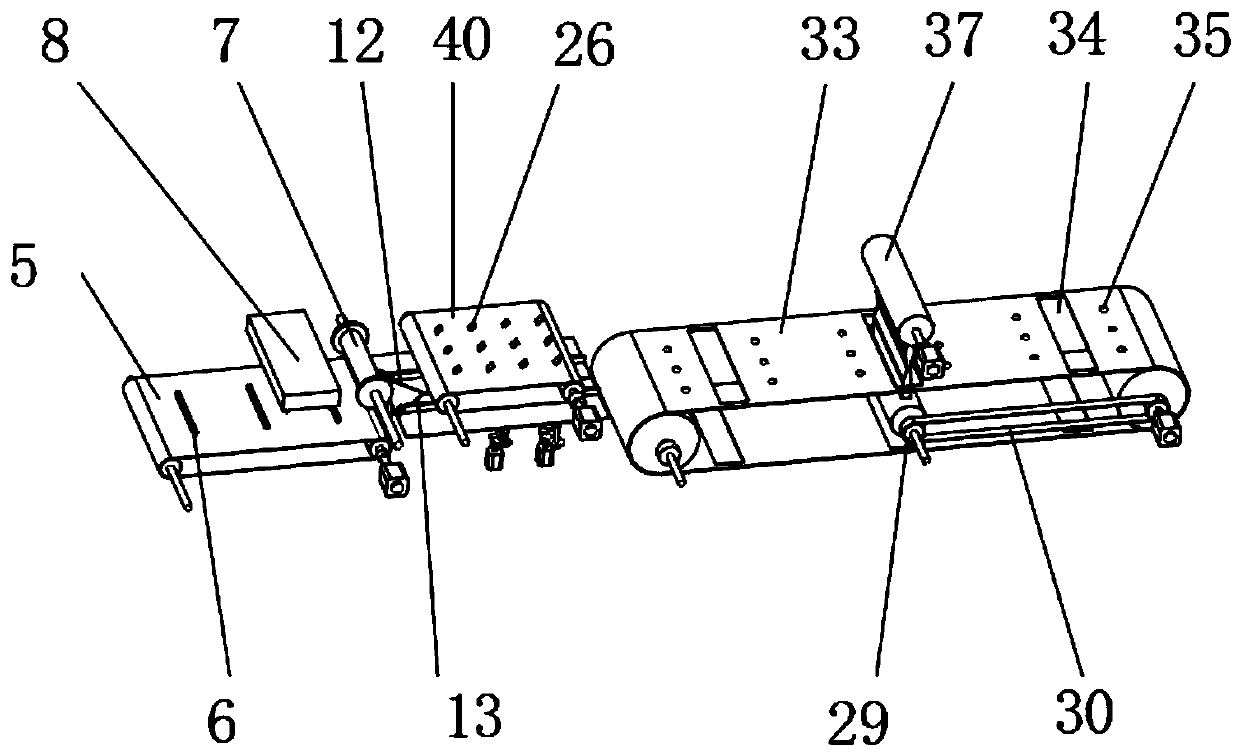

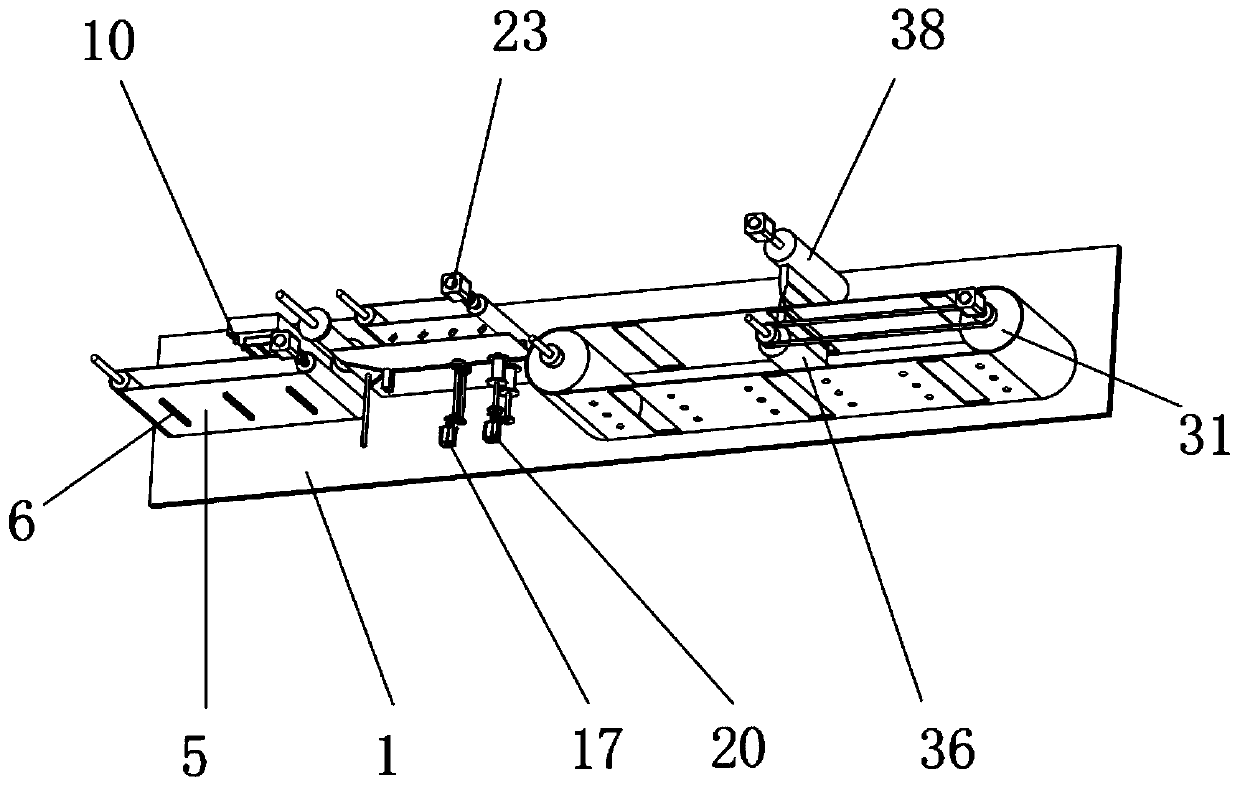

[0031] An integrated conveyor for dedusting and sterilization, such as figure 1 , image 3 , Figure 4As shown, it includes a main body 1, the outer wall of the bottom surface of the main body 1 is welded with the same four support legs 39, and the inside of the main body 1 is provided with a feeding area, a bottom sealing area and an edge sealing area; the feeding area includes a feeding motor 2 And the packaging film cylinder 7, the feed motor 2 is installed on the outer wall of the main body 1 side through the feed motor base, the output end of the feed motor 2 is connected with the feed drum 3 through the feed motor synchronous wheel and shaft rotation, One end of the feed roller 3 is installed on the inner wall of one side of the main body 1 through a shaft and a bearing seat, and the same feed follower roller 4 is installed on the inner walls of both sides of the main body 1 through a shaft and a bearing seat, and the feed follower roller 4 The outer wall and the outer...

Embodiment 2

[0041] An integrated conveyor for dedusting and sterilization, such as figure 1 As shown, in order to solve the problem that the packaging film is easy to get stuck; this embodiment makes the following improvements on the basis of Embodiment 1: the outer wall of the top of the packaging board 11 is welded with an upper guide belt 13, and the outer wall of the bottom of the packaging board 11 is welded with a The lower guide belt 14, the outer wall of the bottom of the packaging board is connected with the auxiliary wheel 15 through the shaft rotation, by setting the upper guide belt 13, the lower guide belt 14 and the auxiliary wheel 15, the packaging film can be pre-folded, so that the film collecting cylinder 19 can Smoother film closing makes the heat-sealing position of the annular heat-sealing knife 16 more accurate, and the upper guide belt 13 also plays a role in guiding the bread simultaneously.

[0042] When the present embodiment is in use, the packaging film is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com