Dead head heating easily-cutting piece of large steel casting

A riser heating and easy-cutting technology, which is applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of casting defects, failure to achieve feeding effect, and casting scrap, so as to improve casting work efficiency and reduce work Difficulty, the effect of reducing the area of the incision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] detailed description: The present invention is specifically described below in conjunction with accompanying drawing:

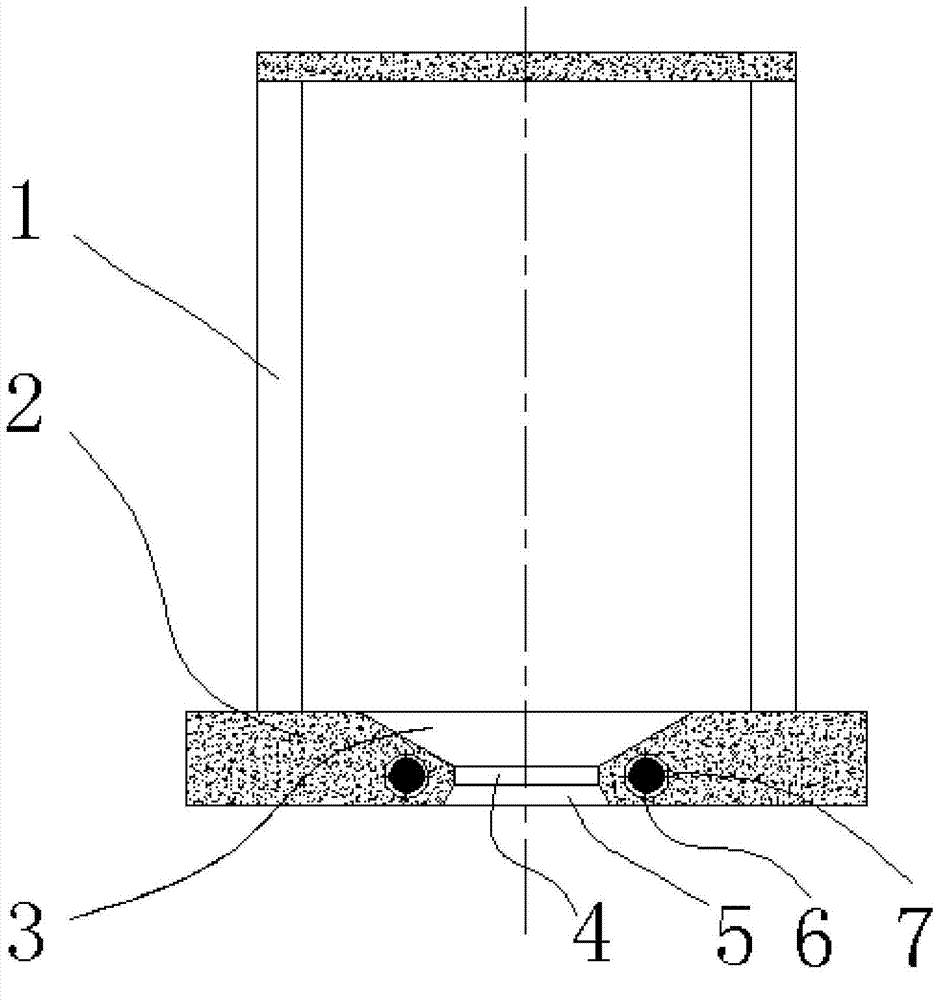

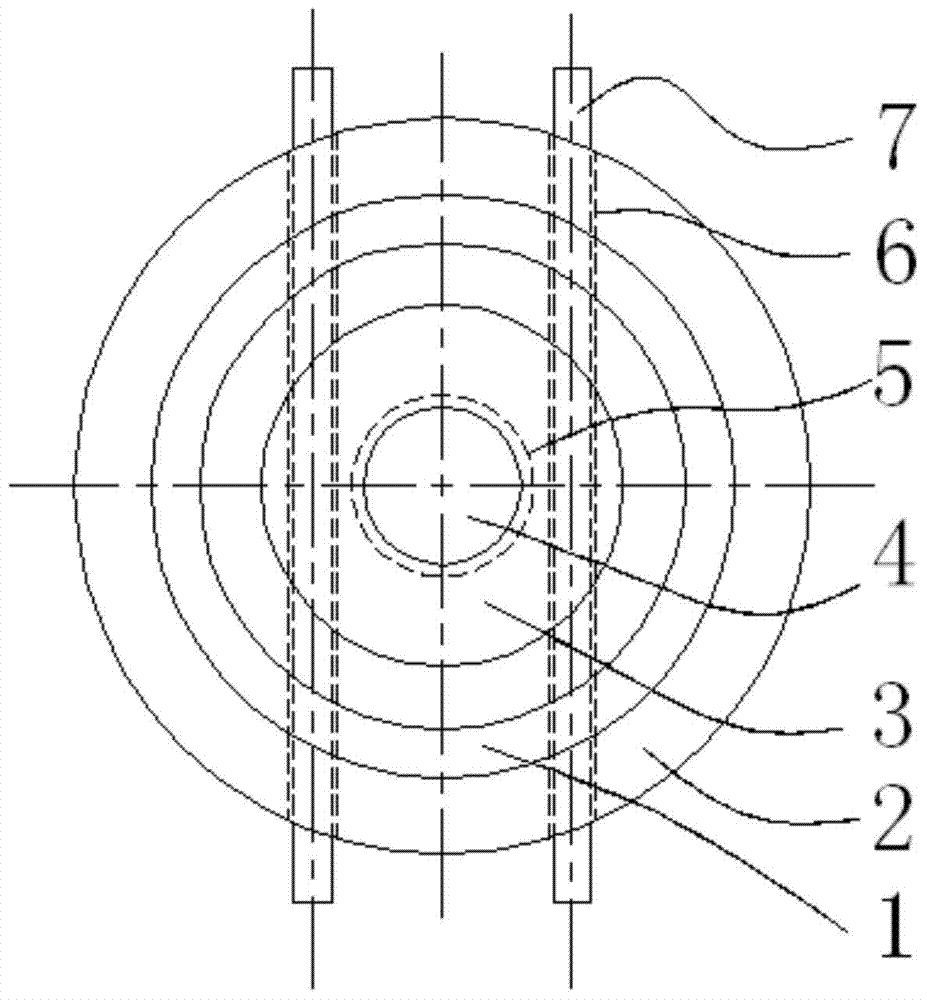

[0017] A large-scale cast steel riser heating easy-cut piece, characterized in that: the easy-cut piece is composed of an upper groove 3, a lower groove 5, a fracture 4, a ceramic sleeve 6 and a heating rod 7, and the upper part of the easy-cut piece The diameter of the groove 3 is smaller than the diameter of the riser 1, the angle between the upper groove 3 and the upper surface of the fracture 4 is 135-150 degrees, and the angle between the lower groove 5 and the lower surface of the fracture 4 is 120-150 degrees The height of the down groove 5 from the surface of the casting is 1 / 5-1 / 4 of the thickness of the easy-cut sheet 2, and the thickness of the fracture 4 is 1 / 5-1 / 4 of the thickness of the easy-cut sheet 2; the heating rod 7 is located on the upper The contact surface of the groove 3 and the riser 1 is perpendicular to the interior of the ...

Embodiment 1

[0021] The utility model relates to a heating easy-cutting piece for a riser of a large steel casting. The easy-cutting piece is composed of an upper bevel, a lower bevel, a fracture and a heating rod. The diameter of the upper bevel is 1 / 2-3 / 4 of the diameter of the riser. The material of the easy-cut sheet requires high strength, air permeability, yield and collapsibility, and it is made of core material. The axis of the riser is collinear with the axis of the easy-cut piece. The angle between the upper groove and the upper surface of the fracture is 150 degrees; the angle between the lower groove and the lower surface of the fracture is 120 degrees. The height of the down groove from the surface of the casting is 1 / 4 of the thickness of the easy-cut sheet.

[0022] The thickness of the fracture is 1 / 4 of the thickness of the easy-cut sheet, and the heating rod is located on the contact surface between the upper bevel and the riser, perpendicular to the interior of the upp...

Embodiment 2

[0024] The utility model relates to a heating easy-cutting piece for a riser of a large steel casting. The easy-cutting piece is composed of an upper bevel, a lower bevel, a fracture and a heating rod. The diameter of the upper bevel is 1 / 4-3 / 4 of the diameter of the riser. The material of the easy-cut sheet is made of the material of the core, which is made by mixing molding materials such as casting sand, molding sand binder and auxiliary additives in a certain proportion. The axis of the riser is collinear with the axis of the easy-cut piece. The angle between the upper groove and the upper surface of the fracture is 135 degrees; the angle between the lower groove and the lower surface of the fracture is 150 degrees. The height of the down groove from the surface of the casting is 1 / 5 of the thickness of the easy-cut sheet.

[0025] The thickness of the fracture is 1 / 4 of the thickness of the easy-cut sheet. When the casting is cooled, the riser can be broken directly, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com