Wire coil device for enameled wire production

An enameled wire and wire reel technology, applied in the field of wire reel devices, can solve the problems of insufficient strength, decomposition, deformation, etc., and achieve the effect of not easy to wear and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

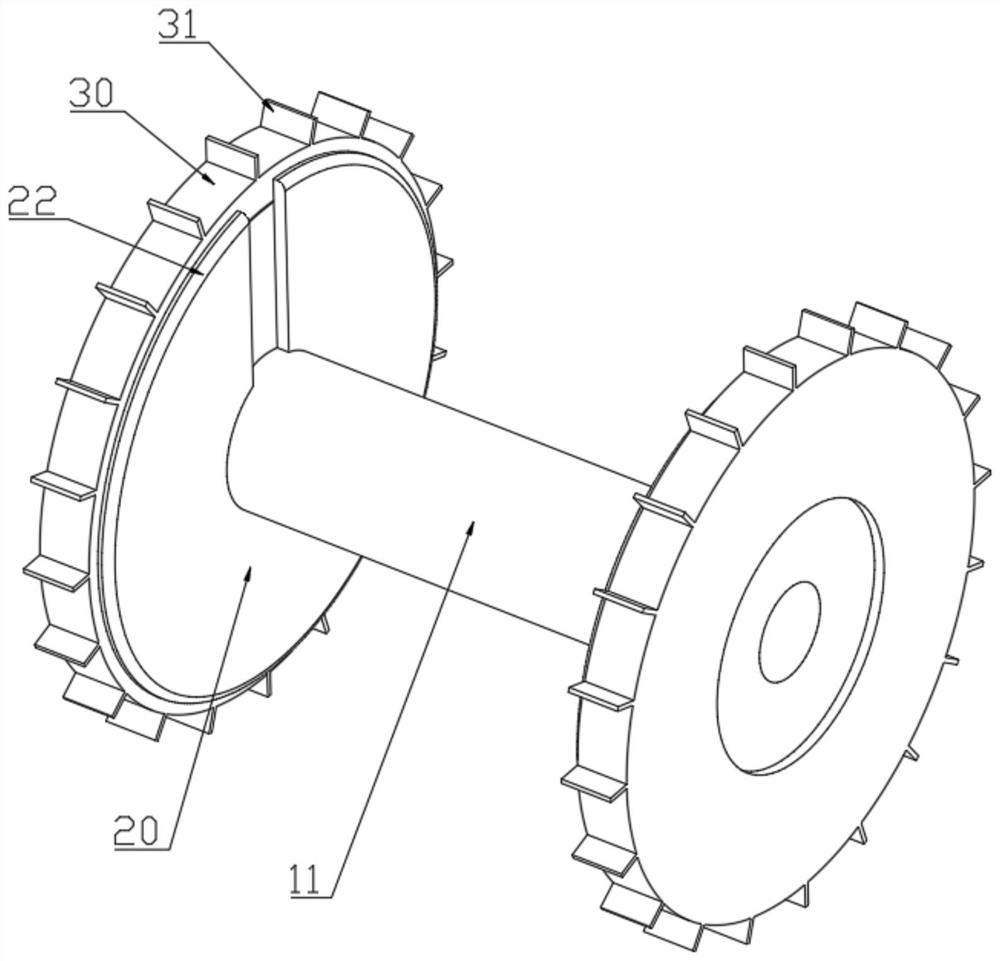

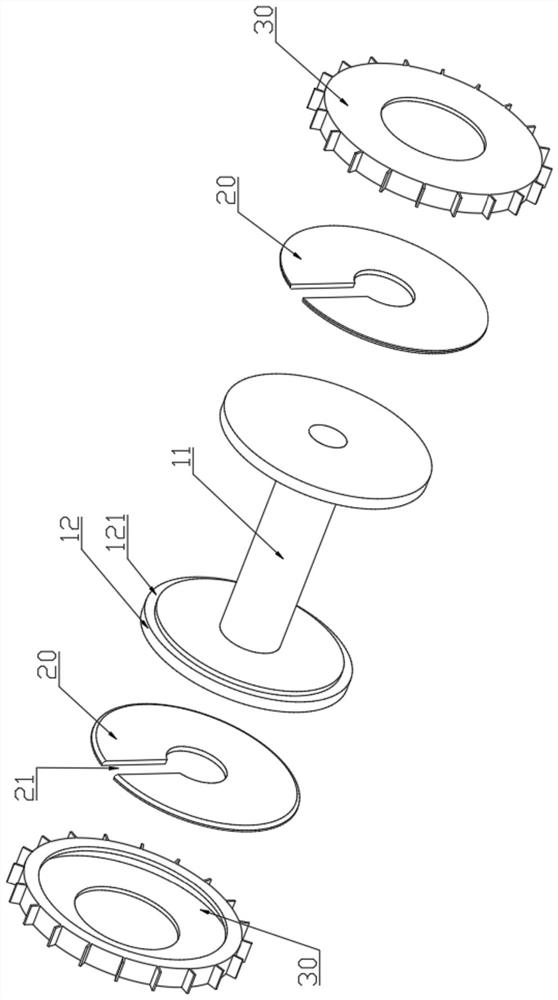

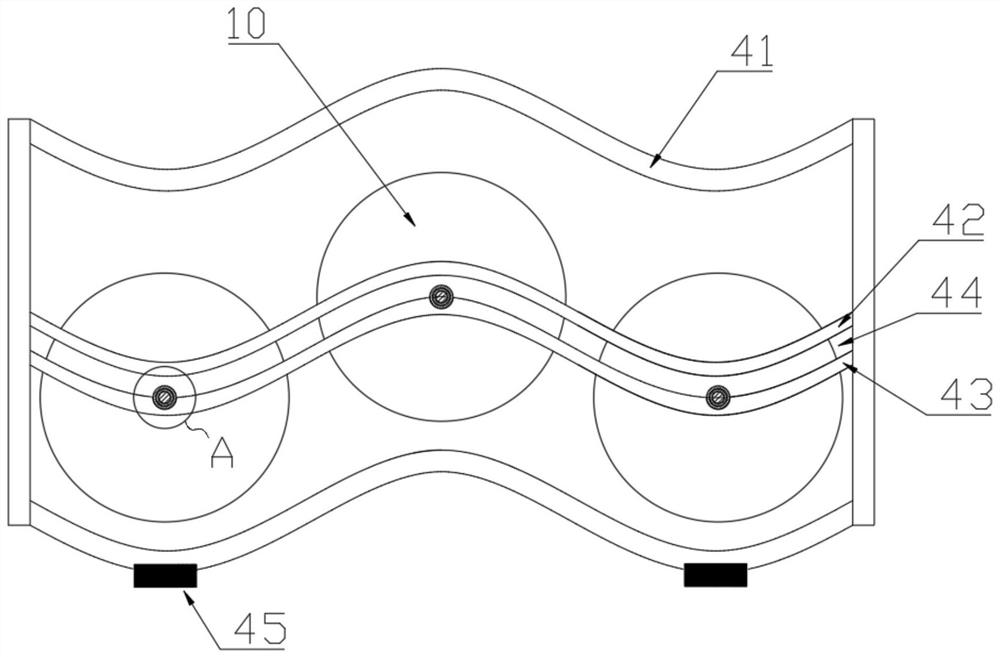

[0029] see Figure 1 to Figure 4 , a wire reel device for enameled wire production according to this embodiment, including a wire reel body 10, a soft material layer 20, two heat dissipation sleeves 30, a wave wire frame, a rotating shaft 50, several bearings 60, and several bearing bushes 70;

[0030] Specifically, the reel body 10 includes a winding roller 11, the two ends of the winding roller 11 are respectively provided with baffles 12; The diameter of wire roller 11; The inner end face of described baffle plate 12 is provided with soft material layer 20;

[0031] More specifically, the soft material layer 20 is provided with an opening 21; by setting the opening 21, the soft material layer 20 can be easily pasted, and at the same time, the soft material layer 20 can be easily torn off after the soft material layer 20 is damaged;

[0032] More specifically, the soft material layer 20 is a silica gel layer; the outer edge of the inner end surface of the silica gel layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com