A single wire transfer device and an integrated wire transfer device composed of the same

A wire transfer and transfer device technology, applied in the direction of coupling device, circuit, connection, etc., can solve the problems of galvanic corrosion at copper-aluminum joints, scattered wires of multiple strands, and mismatched interfaces, so as to achieve strong adaptability and continuous connection. High line efficiency and guaranteed electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preferred embodiment 1: Single wire transfer device for the wiring hole of the electric meter (double extrusion block scheme)

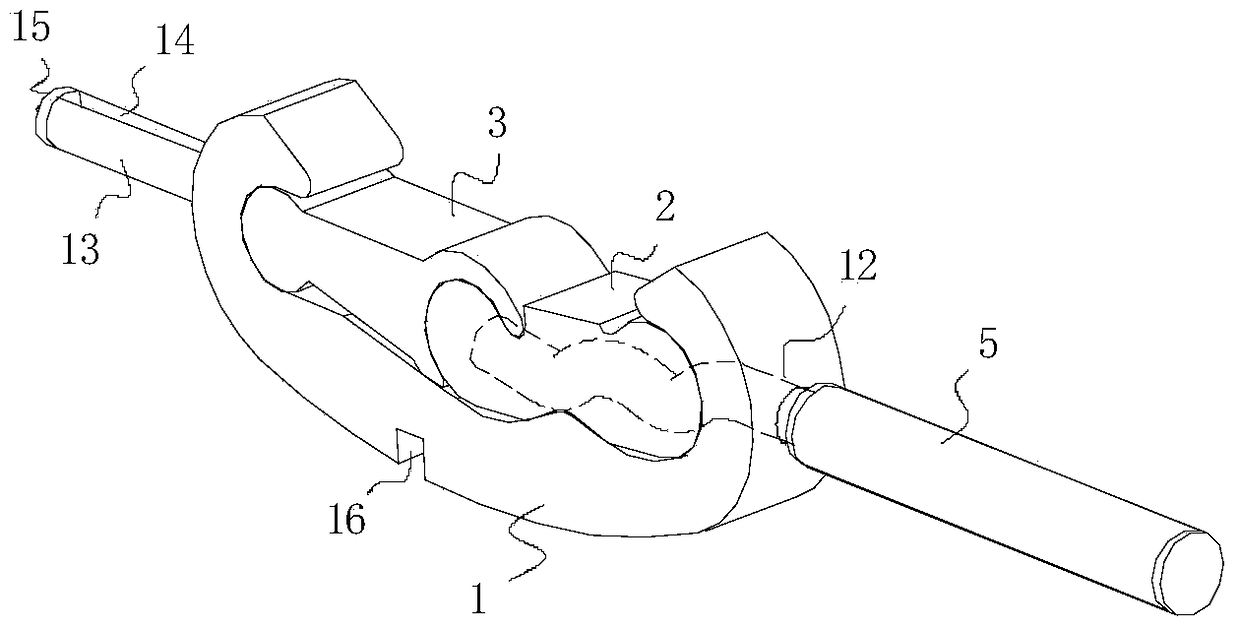

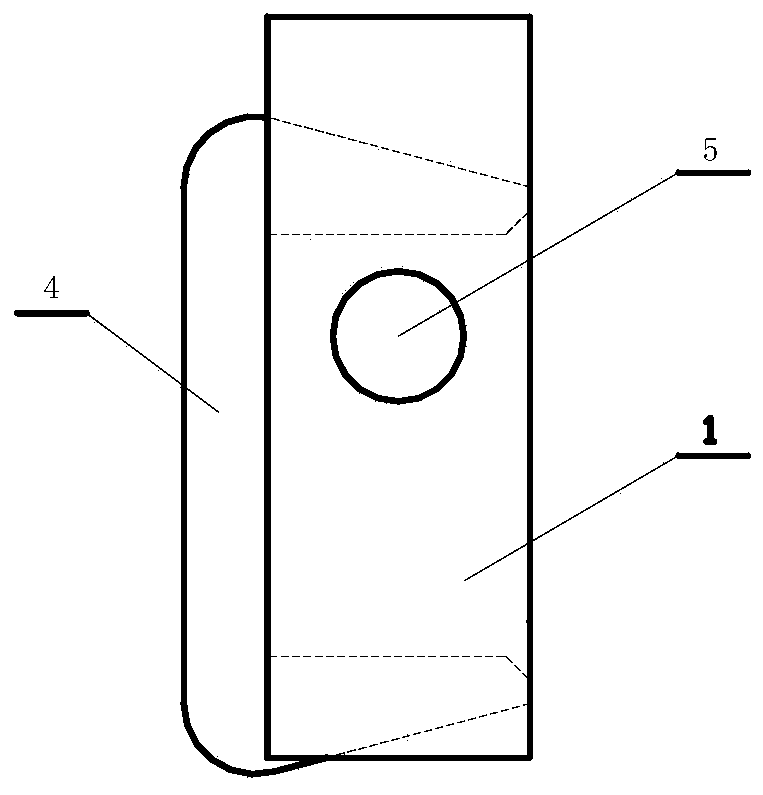

[0049] Figure 1-Figure 6 It is a schematic diagram of preferred embodiment 1 of the present invention. read figure 1 , Figure 5 and Figure 6 It can be seen that the wire transfer device disclosed in this embodiment includes a transfer device body 1 , a first extruding block 2 , a second extruding block 3 and a "ㄈ"-shaped locking member 4 .

[0050] The adapter body 1 is provided with an accommodating cavity 11 , a wire insertion hole 12 and a plug terminal 13 . The insertion terminal 13 is provided with a V-shaped groove 14 and a nail portion 15 . Among them: the V-shaped groove 14 is used to cooperate with the compression screw of the power equipment or the electromechanical product to realize the fixation between the plug-in terminal 13 and the wiring hole, that is, the V-shaped groove is the screw coordination structure of this embo...

Embodiment 2

[0061] Preferred Embodiment 2: A single wire transfer device for the wiring hole of an electric meter (three-extrusion block scheme)

[0062] Figure 7 It is a schematic diagram of a single wire transfer device composed of three extruded blocks. read Figure 7 It can be seen that the embodiment using three extruding blocks includes the adapter body 10, the first extruding block 20 close to the wire insertion hole, the second extruding block 30 close to the plug terminal, and the third extruding block 50 in the middle. and locking screw 40. The adapter body 10 is provided with an accommodating cavity for accommodating three extruded blocks, a wire insertion hole 102 and a plug terminal 103 for connecting to the wiring holes of electric equipment or electromechanical products. The plug terminal 103 is a cylinder with a V-shaped groove 104 , and the plug portion of the plug terminal 103 is provided with a nail portion 105 . The two ends of the accommodating cavity are provide...

Embodiment 3

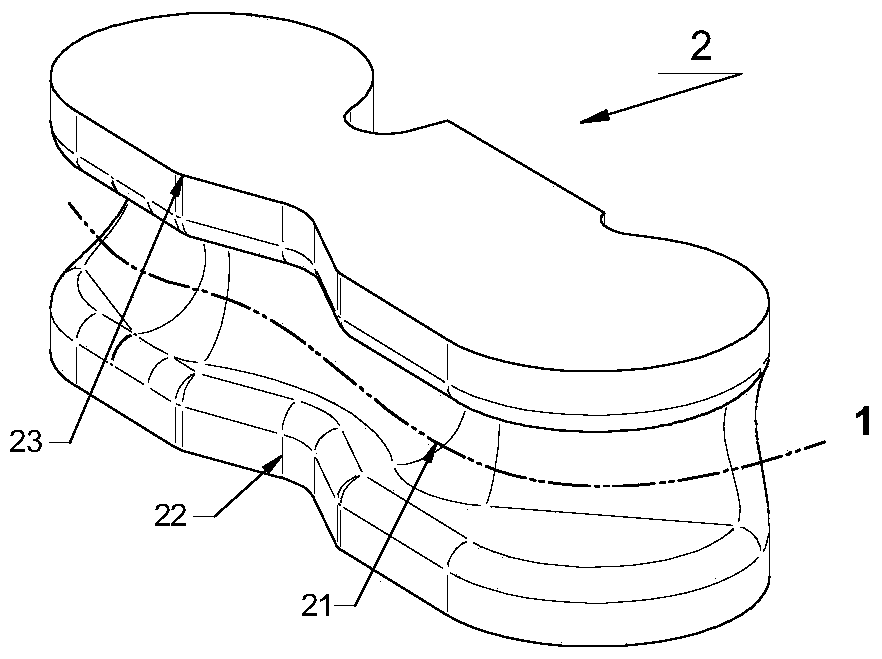

[0065] Preferred embodiment 3: the single body of the crimping groove lengthened type wire transfer device

[0066] Figure 8 It is a schematic structural diagram of a single wire transfer device disclosed in the third preferred embodiment of the present invention. read Figure 8 It can be seen that the cable transfer device with lengthened crimping groove includes a transfer device body 100 , a first extruding block 200 and a second extruding block 300 . The adapter body 100 is provided with an accommodating cavity 1001 , a wire insertion hole 1002 , a plug terminal 1003 , a V-shaped groove 1004 formed on the plug terminal, and a staple portion 1005 provided at the plug portion of the plug terminal. Both ends of the accommodating cavity 1001 are C-shaped structures 1007, and the bottom of the accommodating cavity 1001 is sequentially provided with a first convex portion 1008, a first concave portion 1009, and a second convex portion from the wire insertion hole 1002 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com