A method to overcome cable leakage

A leaky package and cable technology, applied in the direction of communication cables, cable/conductor manufacturing, cables, etc., to achieve the effect of improving insulation performance, reducing abnormal costs, and eliminating mixed lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention proposes a method and a device for overcoming cable leaks to solve problems such as scratched wires, damaged wires, unqualified insulation and other problems caused by leaked wires of local telephone communication cables, as well as wires damaged by longitudinal wrapping molds. The following is combined figure 1 , figure 2 be explained.

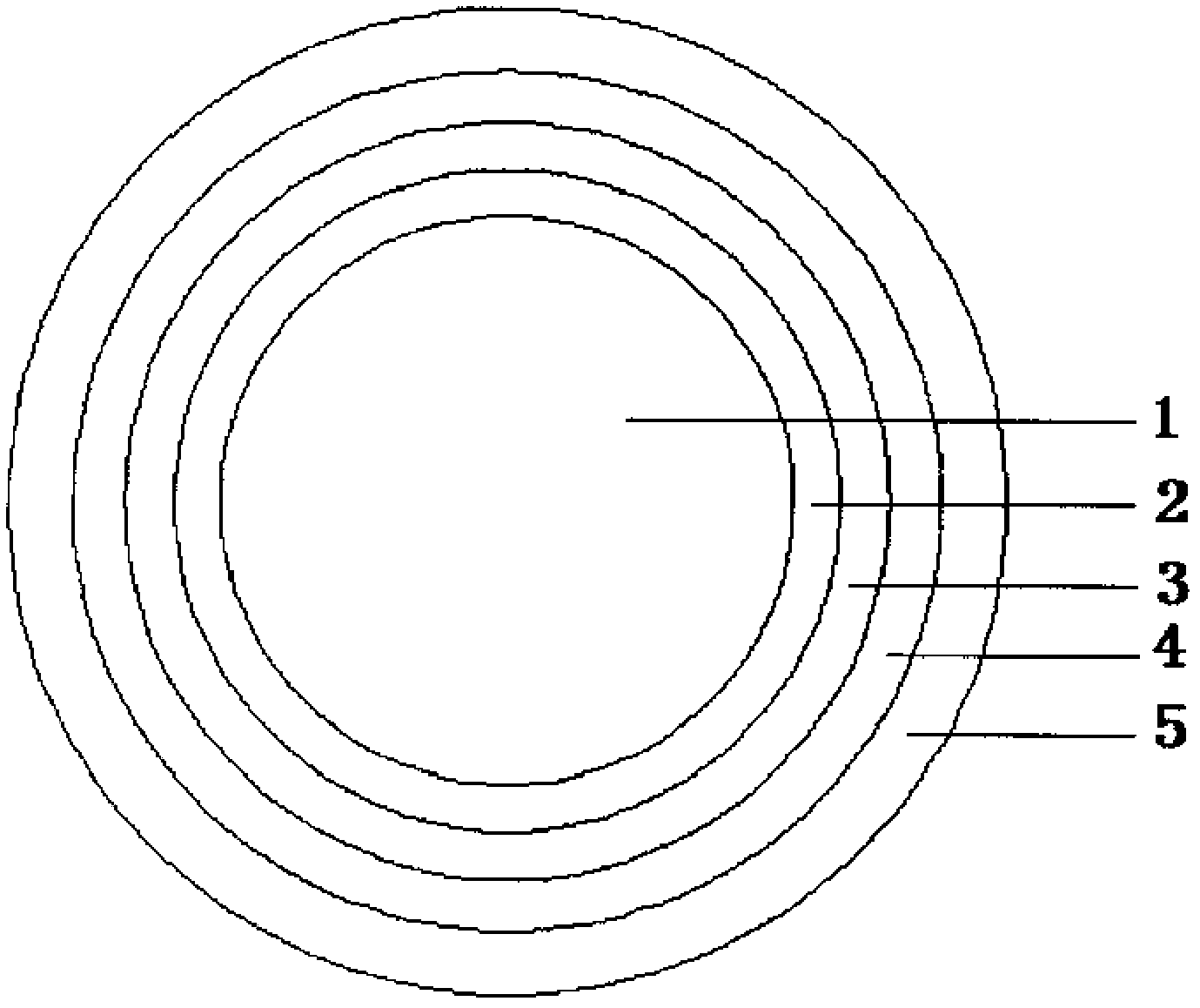

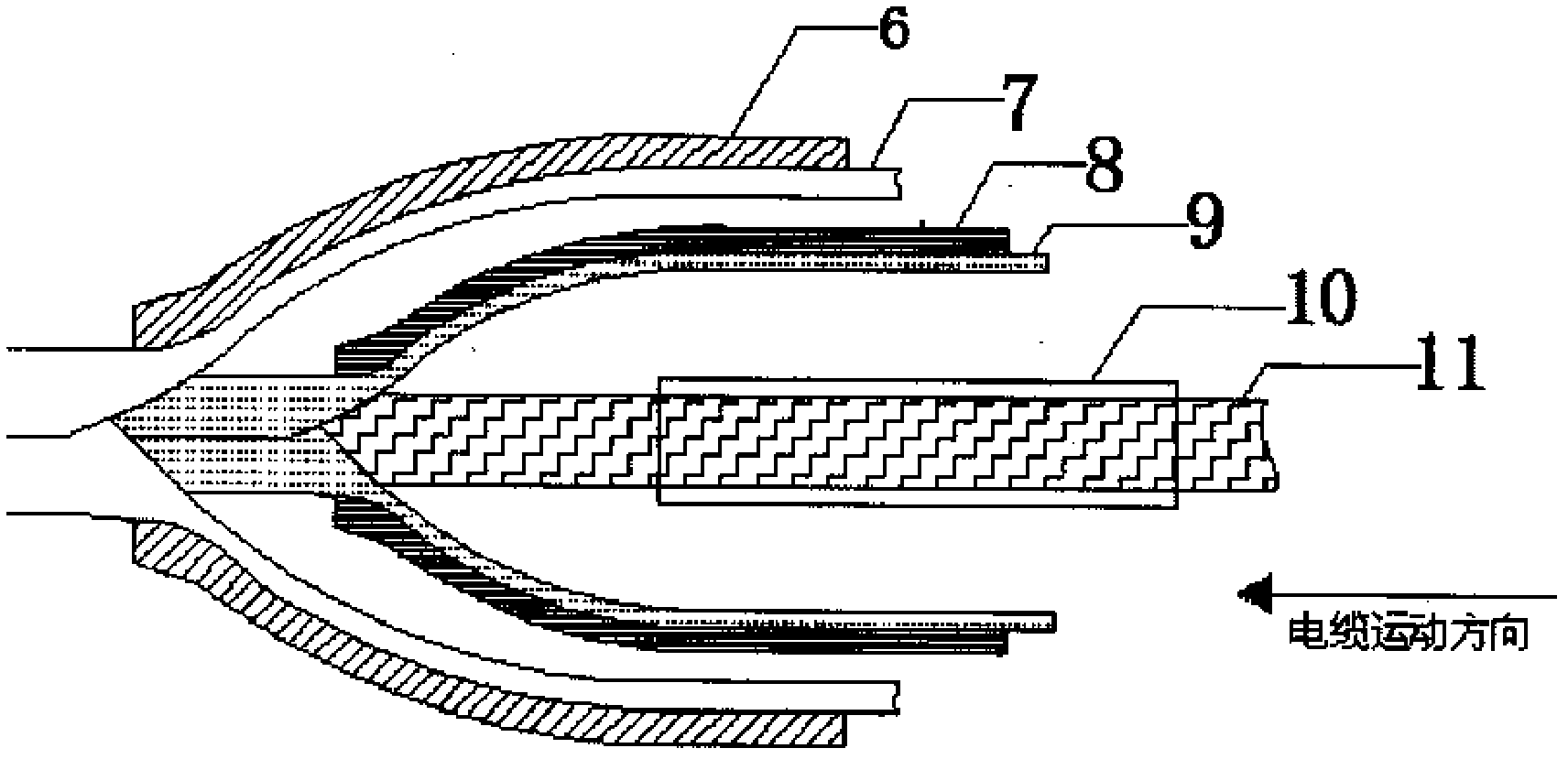

[0012] figure 1 It is a schematic diagram of the structure of the cable after process improvement. The structure of the cable is the cable core 1, the wrapping flexible material wrapping layer 2, the longitudinal wrapping flexible material wrapping layer 3, the aluminum strip longitudinal wrapping layer 4 and the sheath layer 5 from the inside to the outside. Specific process improvements such as figure 2 As shown, the cable core 11 is first wrapped with a flexible material tape, and after passing through the protective tube 10, it enters the flexible material tape longitudinal wrapping mold 8 together with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com