Assembly type shear wall with longitudinal ribs on two sides longitudinally connected through round steel tube concrete

A vertical connection and assembly technology, applied in the processing of walls, building materials, building components, etc., can solve the problems of difficult quality inspection and low installation efficiency, shorten the construction period, improve the structural bearing capacity, and ensure the connection of steel bars Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

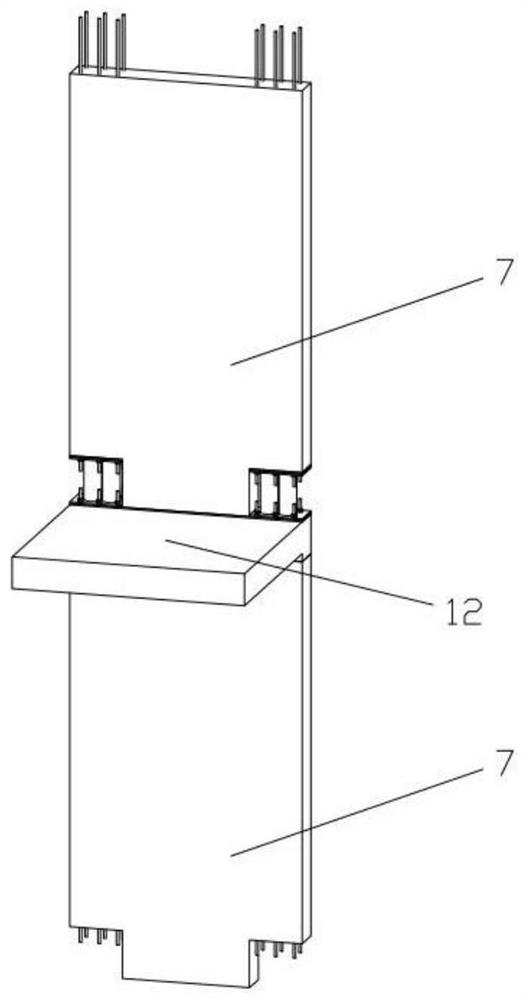

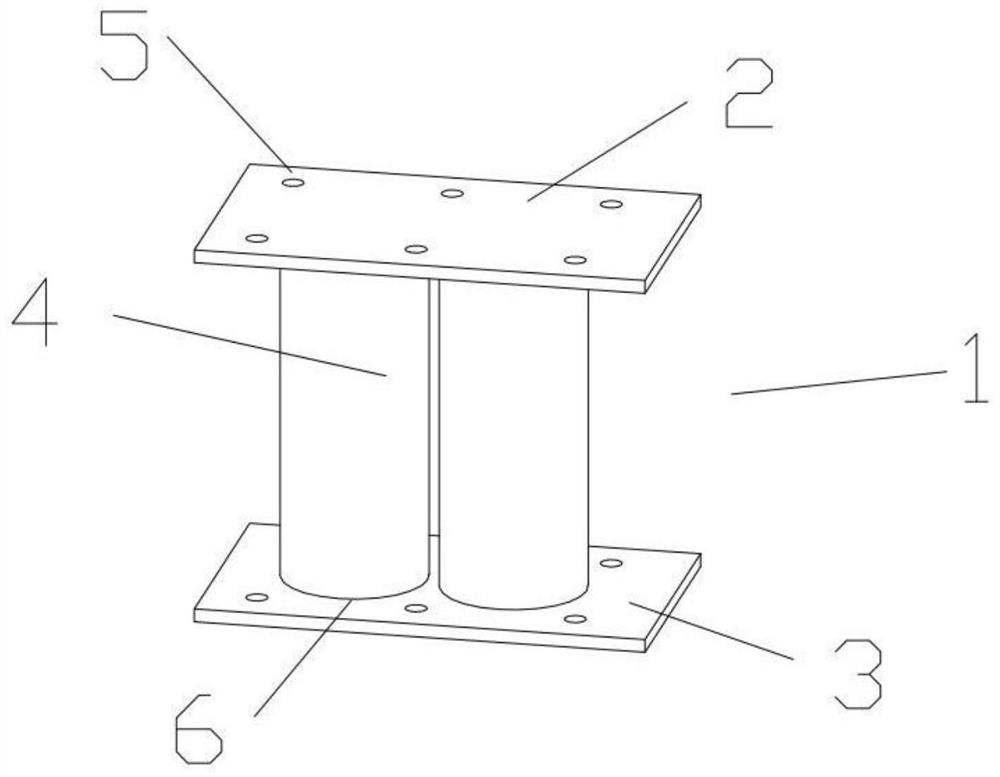

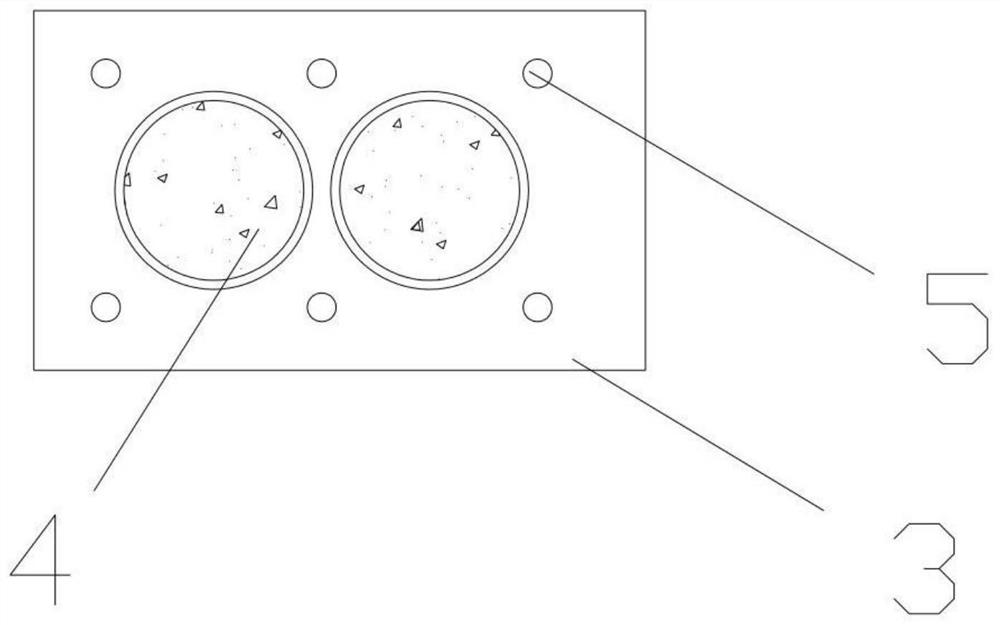

[0051] A prefabricated shear wall in which circular steel tube concrete is longitudinally connected to the longitudinal bars on both sides, characterized in that: the edge member 11 of the prefabricated shear wall unit 7 is provided with longitudinal bars 8 extending from the upper and lower ends of the concrete, and the edge member 11 is provided with The gap provides space for the installation of the connecting device 1. The upper connecting plate 2 of the connecting device 1 is provided with the installation hole 5 through which the lower end of the longitudinal rib 8 of the edge member 11 of the assembled shear wall unit 7 can pass and be connected to it. The lower connecting plate of the connecting device 1 3. Set the installation hole 5 through which the upper end of the longitudinal reinforcement 8 of the edge member 11 of the prefabricated shear wall unit 7 can pass and connect with it. figure 2 , 3 ), vertically connect the prefabricated shear wall units 7 into one (...

specific Embodiment approach 2

[0059] A prefabricated shear wall in which circular steel tube concrete is longitudinally connected to the longitudinal bars on both sides, characterized in that: the edge member 11 of the prefabricated shear wall unit 7 is provided with longitudinal bars 8 extending from the upper and lower ends of the concrete, and the edge member 11 is provided with The gap provides space for the installation of the connecting device 1. The upper connecting plate 2 of the connecting device 1 is provided with the installation hole 5 through which the lower end of the longitudinal rib 8 of the edge member 11 of the assembled shear wall unit 7 can pass and be connected to it. The lower connecting plate of the connecting device 1 3. Set the installation hole 5 through which the upper end of the longitudinal reinforcement 8 of the edge member 11 of the prefabricated shear wall unit 7 can pass and connect with it. figure 2 , 3 ), vertically connect the prefabricated shear wall units 7 into one (...

specific Embodiment approach 3

[0067] A prefabricated shear wall in which circular steel tube concrete is longitudinally connected to the longitudinal bars on both sides, characterized in that: the edge member 11 of the prefabricated shear wall unit 7 is provided with longitudinal bars 8 extending from the upper and lower ends of the concrete, and the edge member 11 is provided with The gap provides space for the installation of the connecting device 1. The upper connecting plate 2 of the connecting device 1 is provided with the installation hole 5 through which the lower end of the longitudinal rib 8 of the edge member 11 of the assembled shear wall unit 7 can pass and be connected to it. The lower connecting plate of the connecting device 1 3. Set the installation hole 5 through which the upper end of the longitudinal reinforcement 8 of the edge member 11 of the prefabricated shear wall unit 7 can pass and connect with it. figure 2 , 3 ), vertically connect the prefabricated shear wall units 7 into one (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com