Mark sample block carbonizing device for wood carbonizing kiln

A technology of carbonization device and carbonization kiln, which is applied in the field of carbonization device for wood mark samples, which can solve the problems of insufficient light, difficult wood carbonization precision control requirements, and inaccurate wood carbonization conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

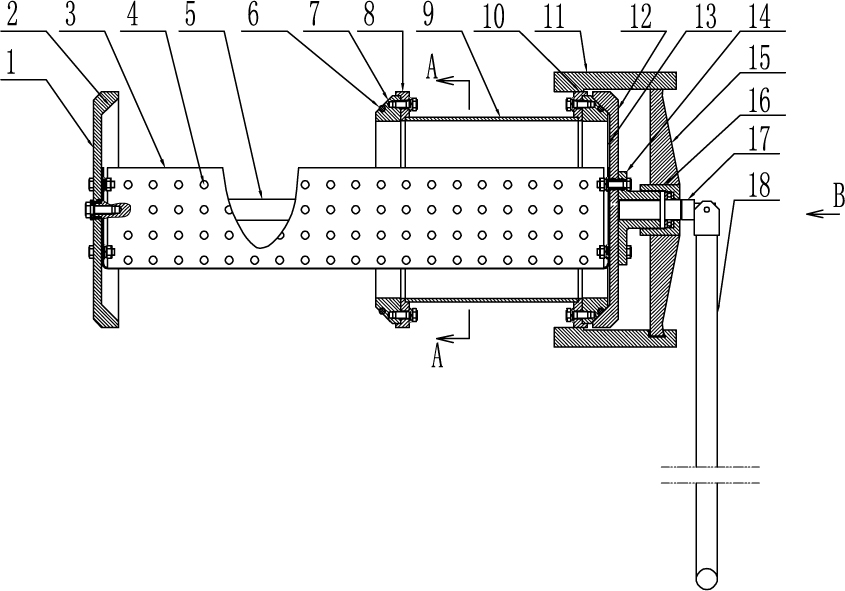

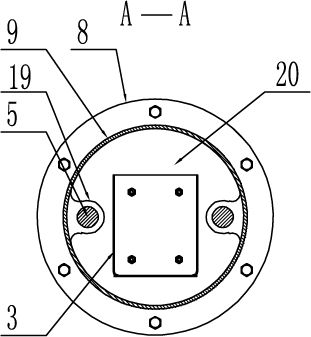

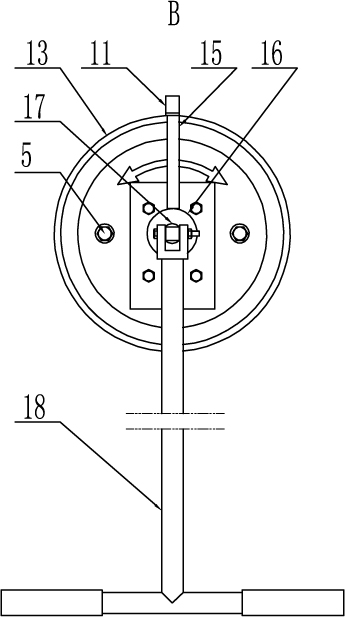

[0018] The wood carbonization kiln carbonization device for marking samples of the present invention comprises a kiln wall channel, a sample block carrying device that can enter and exit the kiln body along the kiln wall channel is installed in the kiln wall channel, and a fixed kiln is installed at the outer end of the sample block carrying device kiln. After the sample block carrying device is pushed into the kiln body, the outer closing door can close the kiln wall channel from the outside of the kiln body. There is a door at the inner end of the kiln of the sample block carrying device. When the sample block carrying device is pulled out of the kiln body, it can be closed from the inside of the kiln body The inner closed door of the closed kiln wall channel is provided with a locking mechanism on the outer closed door to keep the outer closed door and the outer opening of the kiln wall channel sealed. A trough-type sample block bearing device with full contact with the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com