Temperature-control time-control sludge carbonization method and multi-section temperature-control time-control sludge carbonization furnace

A carbonization furnace technology with temperature and time control, applied to fixed carbonization furnaces, pyrolysis treatment of sludge, coke ovens, etc., to achieve the effects of simple operation, good sealing, and avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a sludge carbonization method with temperature and time control. In the first stage, biomass is carbonized at high temperature to obtain biochar; The composite carbon is obtained by co-carbonizing the sludge peat and livestock manure at low temperature.

[0027] Among them, the temperatures of high temperature carbonization, medium temperature carbonization and low temperature carbonization are 700°C, 500°C and 300°C respectively, and the time of high temperature carbonization, medium temperature carbonization and low temperature carbonization are 60min, 30min and 20min respectively.

[0028] Based on the method of embodiment 1, the ratio of the sludge, biomass and livestock and poultry manure added is different, and the nutrient content of the sludge charcoal obtained is different, and the addition amount of biomass, sludge and livestock and poultry manure is 2- by mass ratio When 3:4-5:1, the available potassium in the obtained sludge charcoal...

Embodiment 2

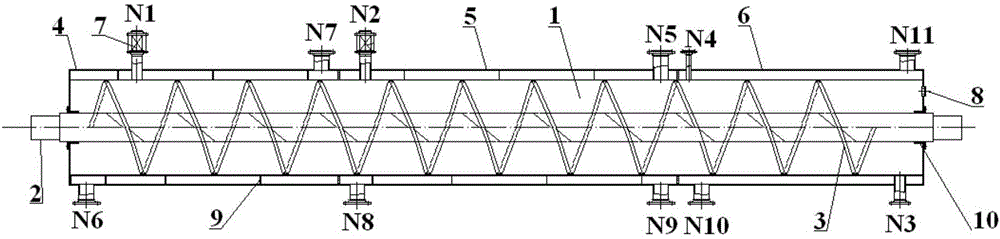

[0031] Comply with the above technical solutions, such as figure 1 As shown, this embodiment provides a multi-stage temperature-controlled and time-controlled sludge carbonization furnace, which includes an inner cylinder 1, and the inner cylinder 1 drives the screw blade 3 on the transmission shaft 2 through the transmission shaft 2 in the inner cylinder 1 to run. The first carbonized raw material inlet N1 and the second carbonized raw material inlet N2 are arranged in turn on the upper side of the front end of the cylinder 1, and the carbide outlet N3 is arranged on the lower side of the end of the inner cylinder 1. The upper side of the inner cylinder 1 is connected to the second carbonized raw material inlet. A conditioner feed port N4 is provided between the feed port N2 and the carbide outlet N3. The conditioner feed port N4 is to add some low-temperature carbonized substances other than biomass during sludge carbonization, so as to change the sludge carbon. nutrient con...

Embodiment 3

[0039] This example provides a multi-stage temperature-controlled and time-controlled sludge carbonization furnace, which uses municipal sludge as raw material to prepare sludge charcoal, which is used for municipal landscaping. In order to reduce energy consumption costs and increase the nutrient content of sludge charcoal, it is necessary to add Co-carbonization of livestock and poultry manure.

[0040]The biomass enters the inner cylinder 1 from the first carbonization raw material inlet N1, and the 800°C high-temperature flue gas enters the high-temperature heating jacket 4 from the high-temperature heat source inlet N6 to the inner cylinder 1 and is discharged from the high-temperature heat source outlet N7. The biomass is carbonized under the heating of the high-temperature heating jacket 1, and converted into biomass charcoal and combustible gas. With the rotation of the spiral blade 3, the biomass charcoal moves to the tail of the inner cylinder 1.

[0041] The municip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com